Hi - I have a 04 Sport that has rusted holes in both rear fenders. It’s the area at the bottom of the front of the rear fender. I have to imagine this is a common problem but I can’t seem to find anyone who makes patch panels. Pics below. Thanks!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Does anyone make body panels?

- Thread starter Nfrancic

- Start date

Welcome to the forum.

Panels might be available but most of what you need in that area is pretty straight forward and easy to make. I patched those areas of my LJ recently. A lot of the repair area will be covered by the flares and in my case the sill covers.

The ends of your torque boxes (the rectangular "holes" in your pics) look pretty crusty. They are available and are a pain in the butt to replace in whole or in part. Follow them from what you show in your pics to the front wheel well area and prod them with a hammer, screwdriver or what ever to assess any damage. In my case one side was good but I had to do the other side. Torque boxes are welded to the floors and are integral to the strength of the tub.

https://www.ebay.ca/itm/33454068430...d=link&campid=5337789113&toolid=20001&mkevt=1

Panels might be available but most of what you need in that area is pretty straight forward and easy to make. I patched those areas of my LJ recently. A lot of the repair area will be covered by the flares and in my case the sill covers.

The ends of your torque boxes (the rectangular "holes" in your pics) look pretty crusty. They are available and are a pain in the butt to replace in whole or in part. Follow them from what you show in your pics to the front wheel well area and prod them with a hammer, screwdriver or what ever to assess any damage. In my case one side was good but I had to do the other side. Torque boxes are welded to the floors and are integral to the strength of the tub.

https://www.ebay.ca/itm/33454068430...d=link&campid=5337789113&toolid=20001&mkevt=1

P

P man

Guest

I'm not aware of any patches for that area..find a tub and cut them out or just use basic steel to make the patches

OP

Thanks for the replies. I’m new to Jeep world and working front to back on the restoration.

Welcome to the forum.

Panels might be available but most of what you need in that area is pretty straight forward and easy to make. I patched those areas of my LJ recently. A lot of the repair area will be covered by the flares and in my case the sill covers.

View attachment 385415

View attachment 385417

The ends of your torque boxes (the rectangular "holes" in your pics) look pretty crusty. They are available and are a pain in the butt to replace in whole or in part. Follow them from what you show in your pics to the front wheel well area and prod them with a hammer, screwdriver or what ever to assess any damage. In my case one side was good but I had to do the other side. Torque boxes are welded to the floors and are integral to the strength of the tub.

https://www.ebay.ca/itm/33454068430...d=link&campid=5337789113&toolid=20001&mkevt=1

This is a very good post- Good job.

As much as I am quick to tell people to try to avoid getting a TJ with much rust, I have the utmost respect for you guys to have to deal with it.

This is a very good post- Good job.

As much as I am quick to tell people to try to avoid getting a TJ with much rust, I have the utmost respect for you guys to have to deal with it.

Thanks. That was a pretty straight forward repair. I used to do ground up restorations on MG's mainly and probably spent more time on the bodies than was warranted. It wasn't that I was meticulous ... just slow. lol. Original body parts in good condition were hard to find and it was common to take sections from 3 or 4 to make one good fender for example. Even with that we had to fabricate a lot of the sheet metal. A lot of time I would spot weld and hammer weld fenders together; that's basically fusion welding with an O/A torch and no filler rod.

As for rusty northern cars, I like to say they make us better welders. Not better than anyone else ... just better than if we didn't have to do it.

Thanks for the replies. I’m new to Jeep world and working front to back on the restoration.

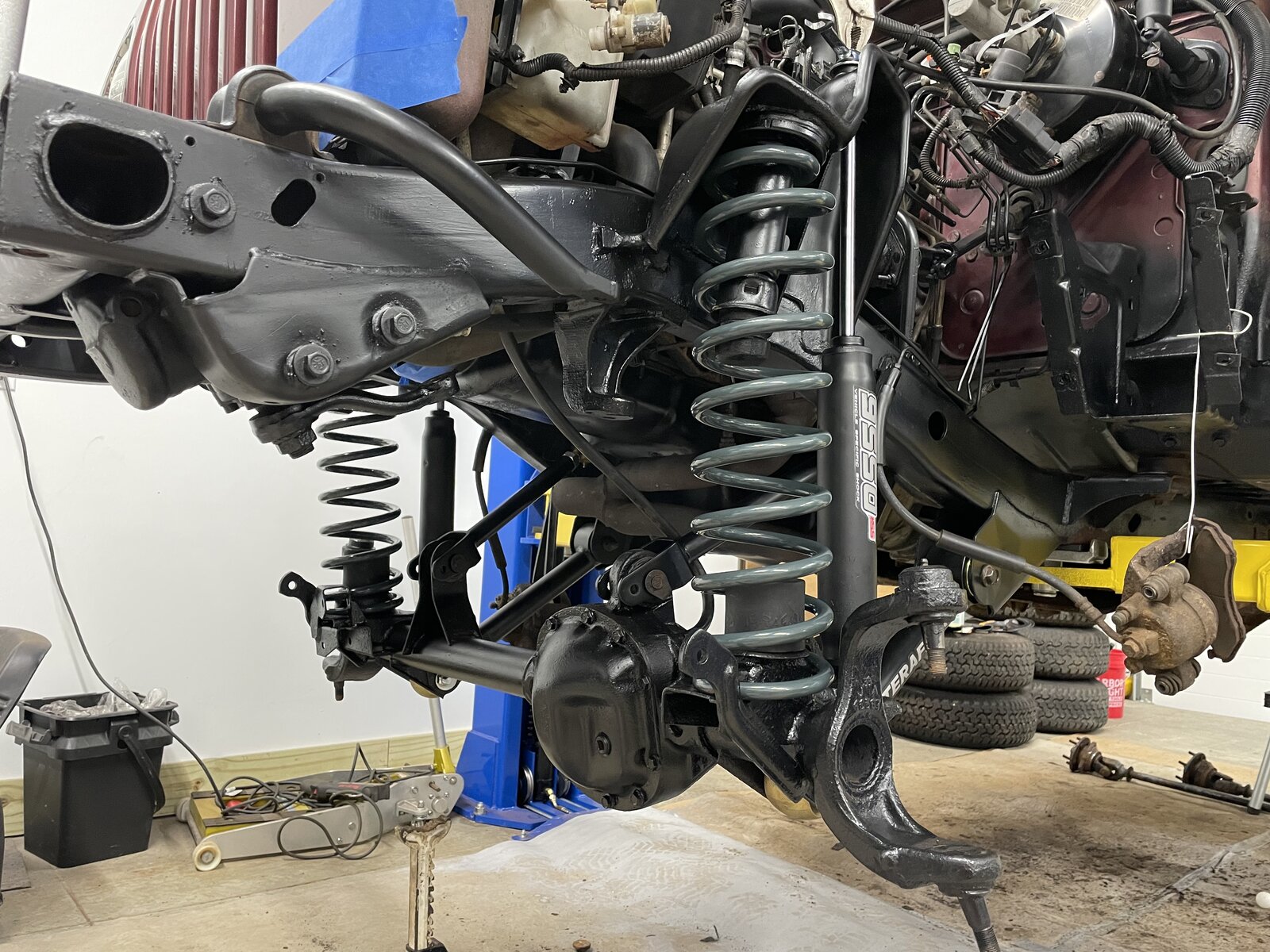

View attachment 385433

The extra hole in the right front upper control arm to pull the axle backward is a trick that I don’t think I’ve seen or heard of-

Vtx531

TJ Addict

Common spot (I have to do mine too) but nobody makes panels for it. I plan on making some pieces to fit from 18 gauge.

Keep us updated when you do the repairs. Love seeing this type of work on a TJ.

Keep us updated when you do the repairs. Love seeing this type of work on a TJ.

OP

The extra hole in the right front upper control arm to pull the axle backward is a trick that I don’t think I’ve seen or heard of-

It’s a Teraflex control arm and the directions said the rear hole is what works for “most applications”. I guess we’ll see…