For those who don't like to obsess over chickenshit details, you'd probably be better off hitting your "back" button now...

For the rest, bear with me for a moment while I lay this out, familiarity with the Warn M8000 would probably help...

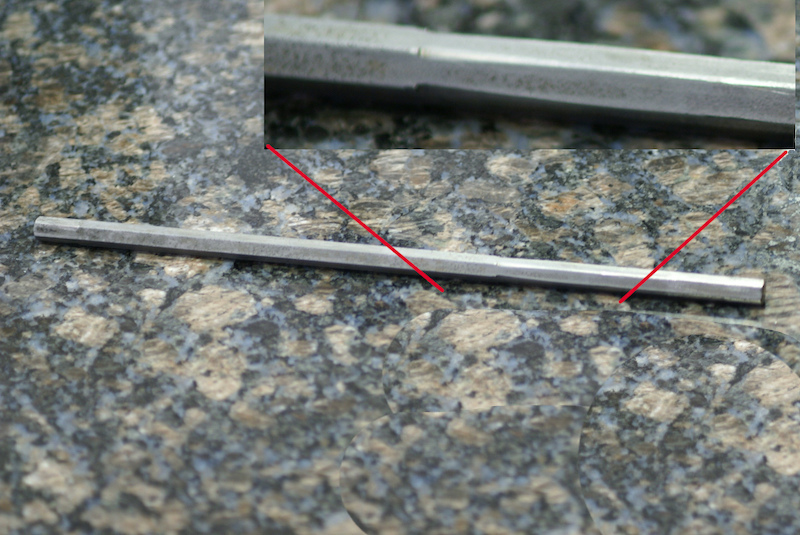

Inset shows wear on the M8000 driveshaft, coincident with where it passed through the 3rd stage planetary via the "Splined Drive"...

Which would be this part right here - note witness marks from the 3rd stage planetary...

Other side of the same part. Note much sharper/less chamfering on this side, which was facing OUT.

Sun gears, old one on the right, which has an obvious problem.

Side view of same.

Old part on the now repainted drive shaft. Note how it cannot pass all the way through, even with part of the swaged on end missing...

An attempt to place the new part in the same relative orientation.

As it has no swaged end on it, the shaft is free to push 1/16" or so further in...

Here's what I think happened: The shaft, for whatever reason, was a BCH too long for the old Sun gear style, so it bowed, and wore on the axial opening of the "Splined Drive" as it (the driveshaft) spins much faster than the splined drive does. Perhaps incompatible revision levels between the shaft and the Sun gear. What with the new style Sun gear, it should relieve the tension and the shaft won't bow - says here.

IN ADDITION: I think the Splined Drive was in backwards, and the more chamfered opening should face outwards. After looking the entire assembly over, I see no reason why the more relieved opening needs to face inwards, yet it might make some sense for it to face outwards. And yes, this winch has "been into" before, no question.

Anyone with any thoughts about an alternate explanation and/or an opinion about the orientation of the Splined Drive part would be appreciated. Makes for interesting speculation if nothing else! I'll probably flip the drive shaft end for end while I'm at it.

For the rest, bear with me for a moment while I lay this out, familiarity with the Warn M8000 would probably help...

Inset shows wear on the M8000 driveshaft, coincident with where it passed through the 3rd stage planetary via the "Splined Drive"...

Which would be this part right here - note witness marks from the 3rd stage planetary...

Other side of the same part. Note much sharper/less chamfering on this side, which was facing OUT.

Sun gears, old one on the right, which has an obvious problem.

Side view of same.

Old part on the now repainted drive shaft. Note how it cannot pass all the way through, even with part of the swaged on end missing...

An attempt to place the new part in the same relative orientation.

As it has no swaged end on it, the shaft is free to push 1/16" or so further in...

Here's what I think happened: The shaft, for whatever reason, was a BCH too long for the old Sun gear style, so it bowed, and wore on the axial opening of the "Splined Drive" as it (the driveshaft) spins much faster than the splined drive does. Perhaps incompatible revision levels between the shaft and the Sun gear. What with the new style Sun gear, it should relieve the tension and the shaft won't bow - says here.

IN ADDITION: I think the Splined Drive was in backwards, and the more chamfered opening should face outwards. After looking the entire assembly over, I see no reason why the more relieved opening needs to face inwards, yet it might make some sense for it to face outwards. And yes, this winch has "been into" before, no question.

Anyone with any thoughts about an alternate explanation and/or an opinion about the orientation of the Splined Drive part would be appreciated. Makes for interesting speculation if nothing else! I'll probably flip the drive shaft end for end while I'm at it.

Last edited: