Oh, the single shear build of the AR is probably fine if both are mounted the same side or opposite. The torsion bar probably puts about half the rated shear strength.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wildman's TJ is getting a face lift

- Thread starter Wildman

- Start date

The 9 (or 3) position will give some adjustability. As you mentioned though it may not be needed. If you are sure it’s not needed, do the angle with angle with best clearance and cut the other holes off for even more room/clearance.

I'm really thinking it isn't going to but like I said I've never had a rear swaybar so I don't know what it's like. When I bought the Jeep whoever installed the lift had removed it. Then when I did the rear axle swap the only way to make a stock type swaybar work it was a shovel with the HP axle.

Oh, the single shear build of the AR is probably fine if both are mounted the same side or opposite. The torsion bar probably puts about half the rated shear strength.

I'm not sure it matters which way the heim is facing but I do agree with Sourbluff that it looks better with it facing the air bags. If the head of the heim rubs on the air bag it's probably better as I'm sure the tire can handle the threads rubbing on it better.

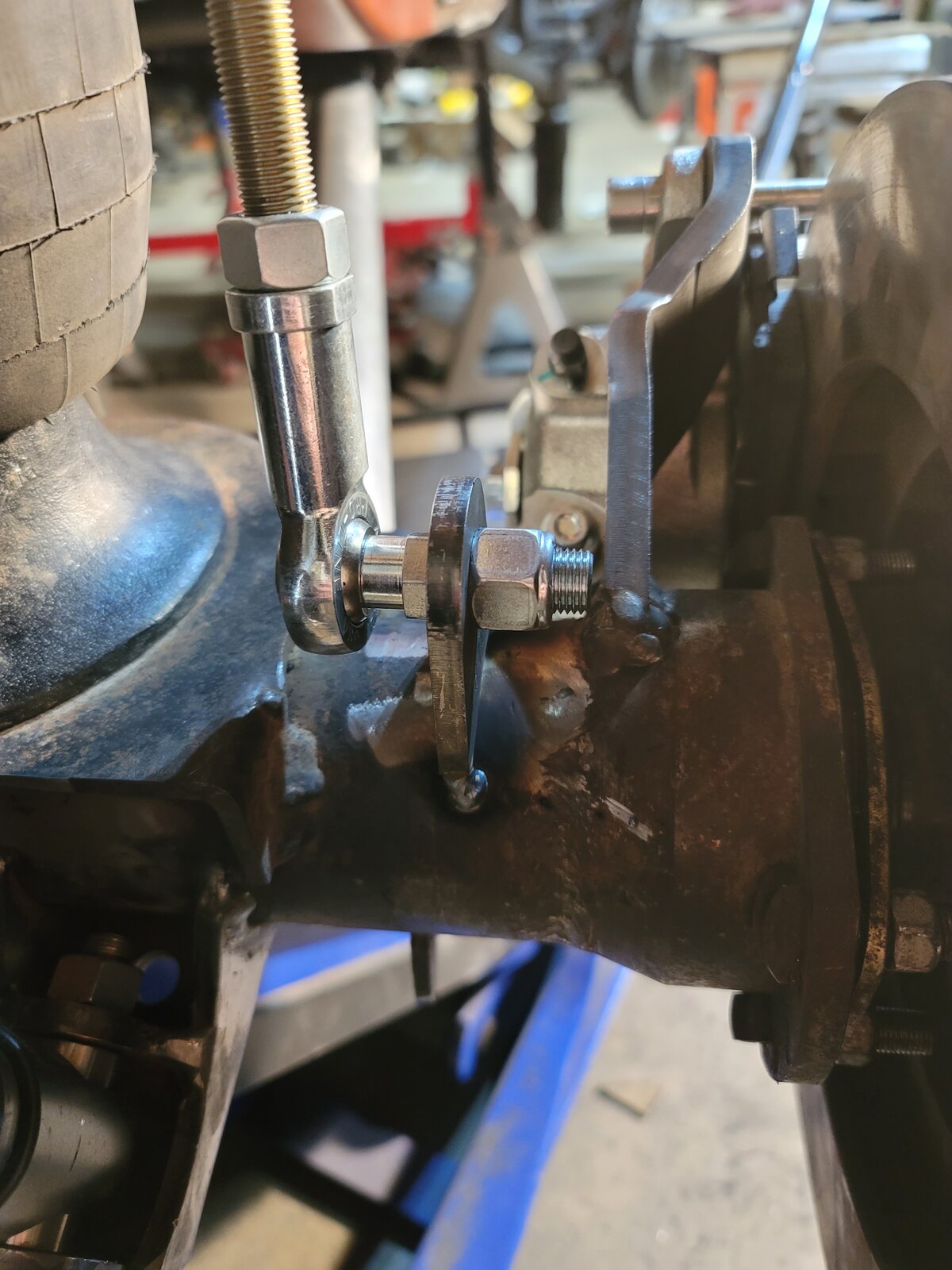

I decided I wasn't gunna worry about having the tab with the holes due to the angle of the link. But also didn't want to cut up the tab from Rock Jock. So I dug out come tabs I had.

I decided to try the cast arms first to see how they fit just for grins & giggles.

So I tacked the tabs on the axle.

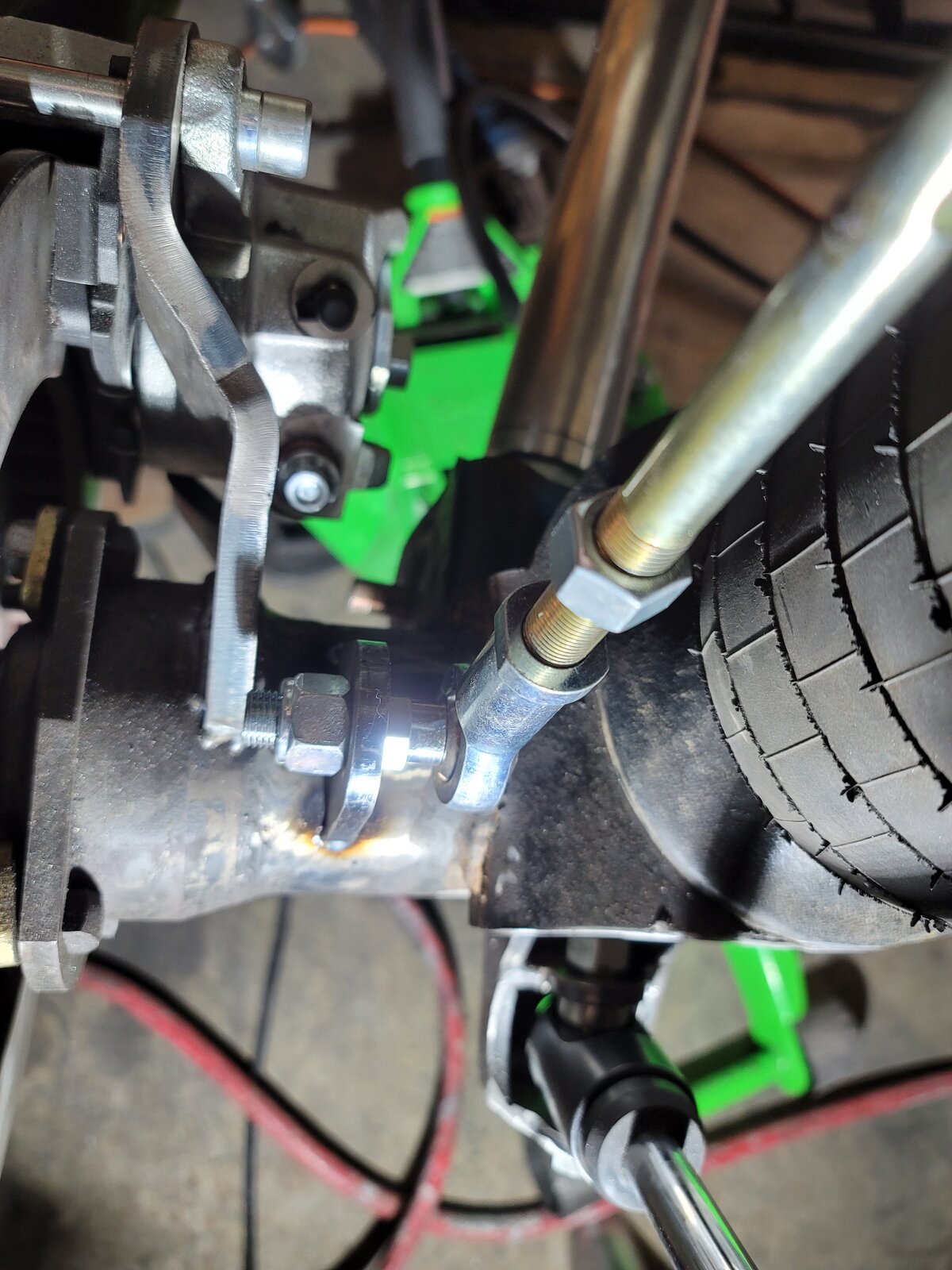

But it stuck out way too far and was into the tire enough that I couldn't hardly turn it. So I slapped the steel arms on after tweaking them a little bit. Then had to take them back off and tweak them AGAIN. 3rd time was a charm this time. The threads of the heim just touch the tire at about 1/2" before full stuff.

So the plan is to pickup some thin jam nuts tomorrow and cut the upper heims down some. I cut the lower tab off and moved it over to match the steel arms.

Now to do this all over again on the other side.

I decided to try the cast arms first to see how they fit just for grins & giggles.

So I tacked the tabs on the axle.

But it stuck out way too far and was into the tire enough that I couldn't hardly turn it. So I slapped the steel arms on after tweaking them a little bit. Then had to take them back off and tweak them AGAIN. 3rd time was a charm this time. The threads of the heim just touch the tire at about 1/2" before full stuff.

So the plan is to pickup some thin jam nuts tomorrow and cut the upper heims down some. I cut the lower tab off and moved it over to match the steel arms.

Now to do this all over again on the other side.

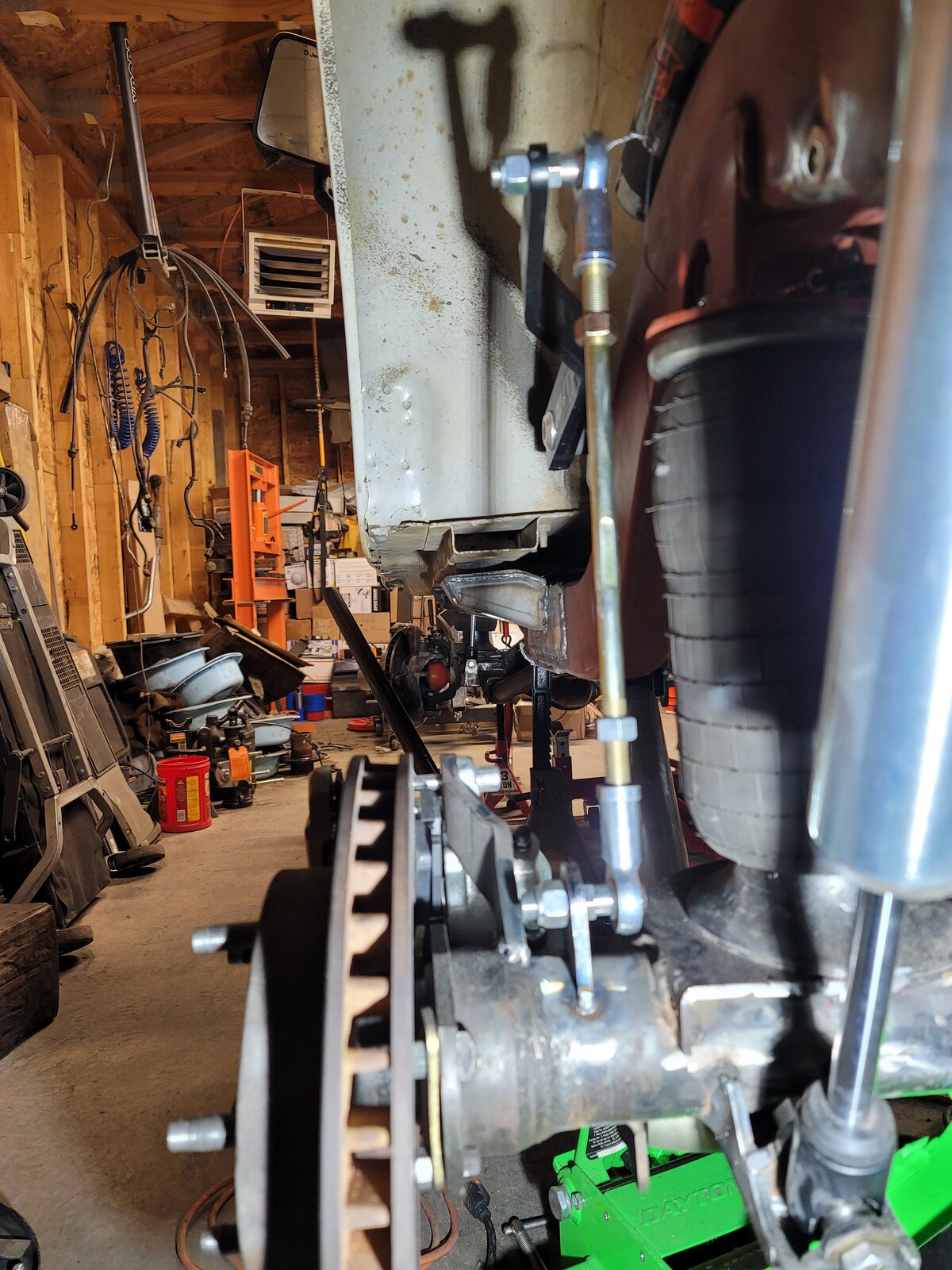

Before I headed to the other side I had to get a shot of the finished product.

I might have to extend the link a bit more to get the heim nut up a little more.

And then the drivers side.

And the tab on the axle welded in place with the link straight.

Once I get the thin nuts and cut the threads off I'll try flexing it more. But I think I've about got this.... Fingers crossed.

I might have to extend the link a bit more to get the heim nut up a little more.

And then the drivers side.

And the tab on the axle welded in place with the link straight.

Once I get the thin nuts and cut the threads off I'll try flexing it more. But I think I've about got this.... Fingers crossed.

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

Did you check to make sure the air bags don't bulge out and hit the bar when they're compressed?Before I headed to the other side I had to get a shot of the finished product.

View attachment 309749

I might have to extend the link a bit more to get the heim nut up a little more.

View attachment 309750

And then the drivers side.

View attachment 309751

And the tab on the axle welded in place with the link straight.

View attachment 309752

View attachment 309753

Once I get the thin nuts and cut the threads off I'll try flexing it more. But I think I've about got this.... Fingers crossed.

I probably wouldve put the link (vertical bar) in front of axle so it wouldn't hit.

Did you check to make sure the air bags don't bulge out and hit the bar when they're compressed?

I probably wouldve put the link (vertical bar) in front of axle so it wouldn't hit.

I had the bags compressed pretty good at full stuff but will look at it again. I'm not sure how you mean to put the link in front of the axle? The arms are the shortest ones they offer. Unless you're suggesting that I drill a hole in arms that puts the link more towards the front of the Jeep?

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

I don't know whats wrong with your body but I got room for days hahahI had the bags compressed pretty good at full stuff but will look at it again. I'm not sure how you mean to put the link in front of the axle? The arms are the shortest ones they offer. Unless you're suggesting that I drill a hole in arms that puts the link more towards the front of the Jeep?

Yep yack it up.... But I also don't have that long body to try and drag thru the trees. And those 5-6 point turns I can do in 2....

And I've got hardly any overhang too.

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

Brooooo you know I'm abouts that cutting brake life!Yep yack it up.... But I also don't have that long body to try and drag thru the trees. And those 5-6 point turns I can do in 2....

And I've got hardly any overhang too.

Brooooo you know I'm abouts that cutting brake life!

Yep, and I'm waiting to see how well they work for you. I wonder if these bigger brakes I've installed could lock up a wheel?

There are times I wish I'd bought a LJ. I went and looked at one right after I'd paid my TJ off. And it was a RubiHara too.

I got an appointment tomorrow morning so won't get a lot done but will hopefully get in a few hours tomorrow afternoon.

Wednesday I've got an appointment at the U of WA for a new foot study and will be picking up the exhaust from the ceramic coating shop.

Thursday I will get some done to it but have to get my truck packed with tools I'll need for a rear axle seal fix. My nieces boyfriend's car has a bad wheel bearing and axle seal and they are broke. And her car lost reverse so I am going to go over and fix his car. Got to be the good uncle. I'm headed over there Thursday afternoon and will come home once it's all fixed. Figuring Friday and maybe part of Saturday. It's a Crown Vic with a 8.8 so it isn't a HUGE job.

Wednesday I've got an appointment at the U of WA for a new foot study and will be picking up the exhaust from the ceramic coating shop.

Thursday I will get some done to it but have to get my truck packed with tools I'll need for a rear axle seal fix. My nieces boyfriend's car has a bad wheel bearing and axle seal and they are broke. And her car lost reverse so I am going to go over and fix his car. Got to be the good uncle. I'm headed over there Thursday afternoon and will come home once it's all fixed. Figuring Friday and maybe part of Saturday. It's a Crown Vic with a 8.8 so it isn't a HUGE job.

jesseshoots

TJ Enthusiast

Good on you for helping out family. Hopefully it brings you some good luck with the rest of your rear axle!I got an appointment tomorrow morning so won't get a lot done but will hopefully get in a few hours tomorrow afternoon.

Wednesday I've got an appointment at the U of WA for a new foot study and will be picking up the exhaust from the ceramic coating shop.

Thursday I will get some done to it but have to get my truck packed with tools I'll need for a rear axle seal fix. My nieces boyfriend's car has a bad wheel bearing and axle seal and they are broke. And her car lost reverse so I am going to go over and fix his car. Got to be the good uncle. I'm headed over there Thursday afternoon and will come home once it's all fixed. Figuring Friday and maybe part of Saturday. It's a Crown Vic with a 8.8 so it isn't a HUGE job.

Also, more studies = more Jeep parts right?

T

TRE3TOP

Guest

Unless you’re going over 110” the TJ is well suited, unless you absolutely need a foot more of storage space.Yep, and I'm waiting to see how well they work for you. I wonder if these bigger brakes I've installed could lock up a wheel?

There are times I wish I'd bought a LJ. I went and looked at one right after I'd paid my TJ off. And it was a RubiHara too.

Good on you for helping out family. Hopefully it brings you some good luck with the rest of your rear axle!

Also, more studies = more Jeep parts right?

Got to pay it forward right? My BIL isn't very mechanically inclined so I've always been the go to guy for stuff.

And YES more studies mean more Jeep funds.

Unless you’re going over 110” the TJ is well suited, unless you absolutely need a foot more of storage space.

Up until a few years ago I needed the additional storage space as I had more than 2 people in the rig. So when I was looking at LJ's it was for the added space.

T

TRE3TOP

Guest

I would like the extra space, but not enough to start over…Got to pay it forward right? My BIL isn't very mechanically inclined so I've always been the go to guy for stuff.

And YES more studies mean more Jeep funds.

Up until a few years ago I needed the additional storage space as I had more than 2 people in the rig. So when I was looking at LJ's it was for the added space.

I picked up my exhaust this morning. WOW it looks awesome.

And I ran into a guy who does V-8 swaps in Jeeps. So I've got a bunch of info to share.

And I ran into a guy who does V-8 swaps in Jeeps. So I've got a bunch of info to share.

OK back home from the UW and man am I excited about this new socket study that I'm getting involved in.

Bu the KEWL part was that as I was picking up the exhaust I can into someone who has a shop in Buckly, WA and he do custom vehicle work. So he does a LOT OF JEEP V-8 swaps and will make a wiring harness for around $800 for anyone who is thinking about doing a V-8 swap on your rig. He supplies the harnesses also.

Anyone in the Seattle area that needs ceramic coating done you have got to check out Performance Coating in Auburn. These guys were AWESOME. And it only cost me $130 to get my parts done. This is coated inside and out.

I'm very impressed with the work and can't wait to get this installed on the Jeep just to see how much it helps with the heat under the hood.

Bu the KEWL part was that as I was picking up the exhaust I can into someone who has a shop in Buckly, WA and he do custom vehicle work. So he does a LOT OF JEEP V-8 swaps and will make a wiring harness for around $800 for anyone who is thinking about doing a V-8 swap on your rig. He supplies the harnesses also.

Anyone in the Seattle area that needs ceramic coating done you have got to check out Performance Coating in Auburn. These guys were AWESOME. And it only cost me $130 to get my parts done. This is coated inside and out.

I'm very impressed with the work and can't wait to get this installed on the Jeep just to see how much it helps with the heat under the hood.

@WSS you'd posted before about being careful with the ceramic coating on my headers so I'll assume the same apply to the Y-pipes.

When I do finally get the Jeep reassembled and go to fire off the engine for the first time are there any precautions I need to take with the coated headers and exhaust? They did include some basic directions but all it says in them is to not run the engine on a dyno until you have a minimum of 3 heat cycles on the exhaust.

Appreciate any help as this is my first time with using ceramic coated parts.

When I do finally get the Jeep reassembled and go to fire off the engine for the first time are there any precautions I need to take with the coated headers and exhaust? They did include some basic directions but all it says in them is to not run the engine on a dyno until you have a minimum of 3 heat cycles on the exhaust.

Appreciate any help as this is my first time with using ceramic coated parts.

I did notice the ceramic coating on my headers scratched if you are not careful. I assume that's normal, but I don't know. My first heat cycle was on the dyno, but I didn't really have a choice. My engine guy told me not to run it at all with a stock tune. I've suffered no ill effects as far as I can tell.@WSS you'd posted before about being careful with the ceramic coating on my headers so I'll assume the same apply to the Y-pipes.

When I do finally get the Jeep reassembled and go to fire off the engine for the first time are there any precautions I need to take with the coated headers and exhaust? They did include some basic directions but all it says in them is to not run the engine on a dyno until you have a minimum of 3 heat cycles on the exhaust.

Appreciate any help as this is my first time with using ceramic coated parts.

It is the weld spatter and even grinding sparks to a lesser degree that damages the coating. Handling them should be fine. even before the heat cycles, they are tough and scratch resistant.@WSS you'd posted before about being careful with the ceramic coating on my headers so I'll assume the same apply to the Y-pipes.

When I do finally get the Jeep reassembled and go to fire off the engine for the first time are there any precautions I need to take with the coated headers and exhaust? They did include some basic directions but all it says in them is to not run the engine on a dyno until you have a minimum of 3 heat cycles on the exhaust.

Appreciate any help as this is my first time with using ceramic coated parts.

My problem was doing a bunch of welding/cutting/fitting with the headers mocked up/installed. The headers did not peel but you could see and feel the hot sparks embedded in the surface.