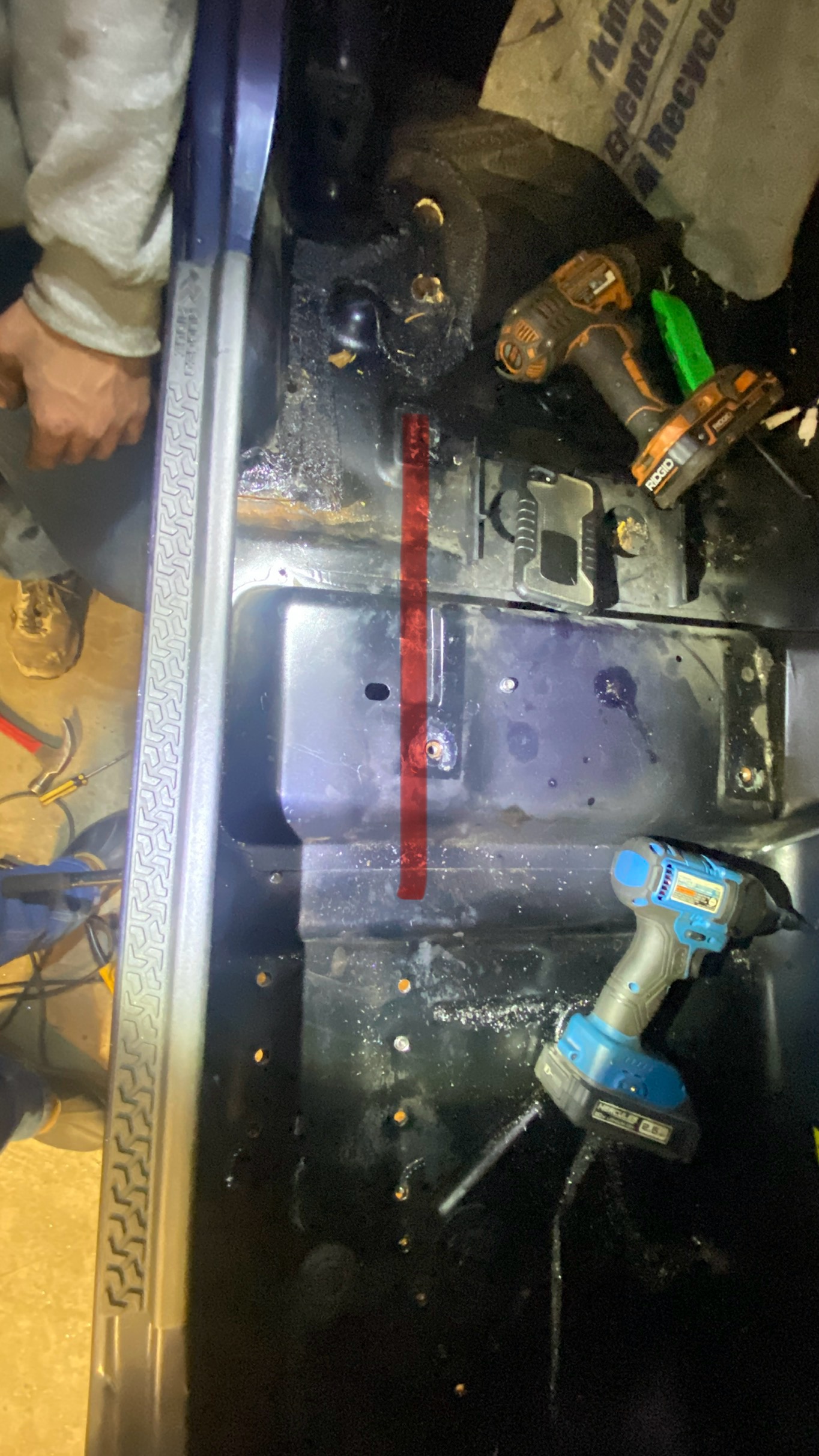

@PCO6 and @Vtx531 how do you get to the spot welds along the red line? I’m sending this for @KJT. He’s out in the garage working on it.

Also, how in the heck do you find some of the spot welds? He can't see them at all. He wire-wheeled some of it to get the rust off in hopes of finding them, but the torque box still seems rather sturdy, so there must be several more.

Also, how in the heck do you find some of the spot welds? He can't see them at all. He wire-wheeled some of it to get the rust off in hopes of finding them, but the torque box still seems rather sturdy, so there must be several more.

Last edited: