Intro

I wanted to add heated side mirrors to my Jeep, since I get freezing rain occasionally here in the Midwest and it’s not super easy to scrape off a thick layer of ice. They’re also handy for foggy/dewy mornings. I had seen a Toytoa Tacoma post about somebody using snowmobile grip heaters for DIY heated mirrors. And started to do some research. I figured I could add some LED turn signal repeaters on the mirrors while I was at it.

This information applies to the 2003-2006 style side mirrors. It will probably not apply to the older style side mirrors.

I ordered some used side mirrors from eBay and proceeded to disassemble them. I used a heat gun to soften the adhesive on the mirror glass and used trim tools to carefully slide in behind the glass and break the adhesive bond. I had to clean up the glass and the mirror mount of residual adhesive using a plastic scraper and mineral spirits. Then did a good cleaning with isopropyl alcohol to remove residue.

For the purposes of this write up, these are the terms I will use for the following parts.

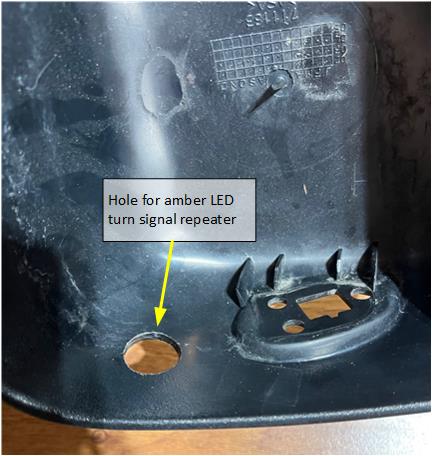

Hole for LED turn signal repeater

I decided on ¾” round LED bullet markers for the turn signal repeater. I marked holes in the mirror housing and drilled holes. The LEDs I had just pop into the hole and stay in place with the grommet.

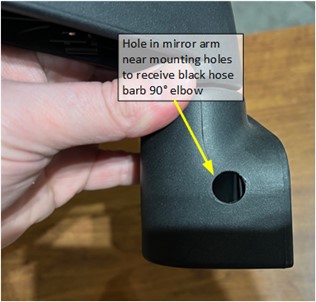

Hole for 90° barbed elbow

I wanted the wiring to look clean and tidy on the mirror, so I found some black hose barb elbows with ¼” NPT threads. I marked and drilled the mirror mounting brackets, and used a brass fitting with ¼” NPT threads to more or less tap the hole for the plastic threads. I used non-split loom over the hose barbs and black nylon hose clamps to keep it in place. This didn’t need to be water tight by any means, but provided very clean fit and finish. The non-split loom was zip tied to a zip tie anchor under the mirror arm, and routed up towards the mirror housing.

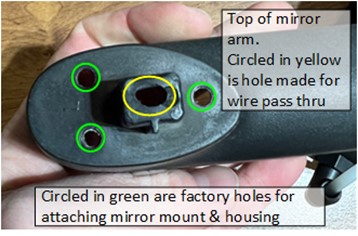

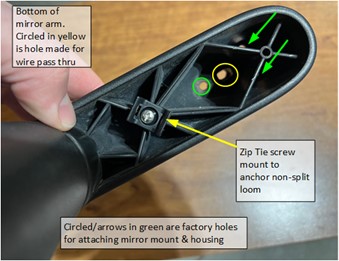

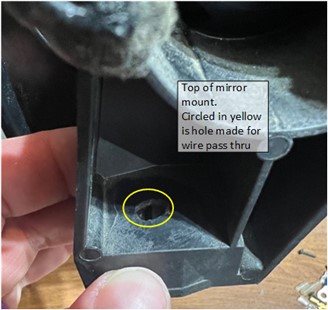

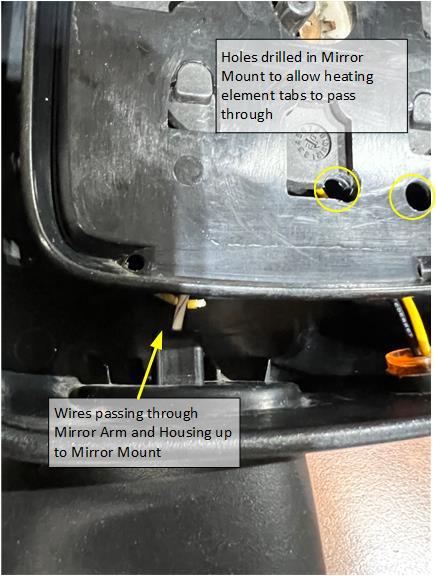

Holes for wire pass through

I needed to drill some holes through the mirror arm and the mirror mount. This would allow the wires to pass into the mirror housing. The hold would need to accommodate three wires (power for LED repeater, power for heating element, and a ground).

Apparently I didn't take many pictures while mounting the heating elements to the mirror glass. Sorry.

-EDIT- I found some pictures.

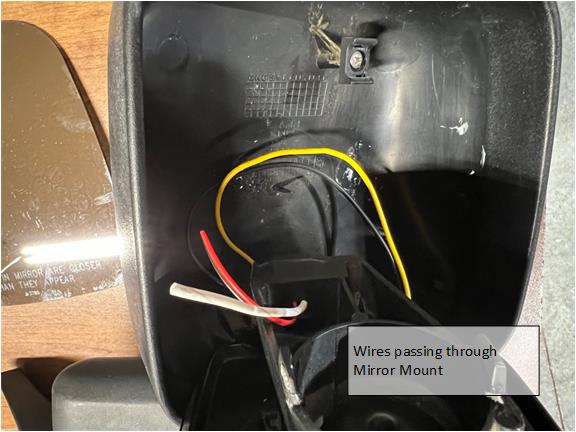

The heating element wires were routed through the mirror mount and into the mirror housing. Once the heating element was adhered to the mirror glass, I used 3M VHB tape to affix the glass to the mirror mount surface.

This tape is remarkably strong and has good temperature resistance and thermal expansion capability. I remember from an episode of I think Modern Marvels, that this is what was used to install the windows in the Burj Khalifa in Dubai to deal with the thermal expansion in the desert heat and cold.

Here's a bench test of the heated mirror. I place the mirror in my freezer for a bit, and then pulled it out to let it fog up and hooked it to a 12V battery.

Ground wires inside the mirror housing for the LED and heating element were connected to the ground wire exiting the housing.

I had some difficulty trying to get the three wires through the barbed elbow. It was just such an abrupt direction change, and the wires didn’t all want to change direction. I eventually did get everything through, used a little bit of wire pulling lubricant

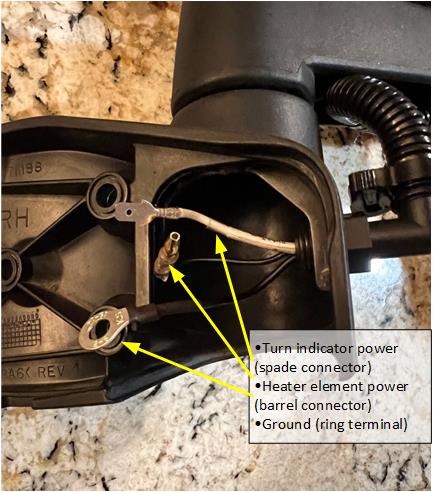

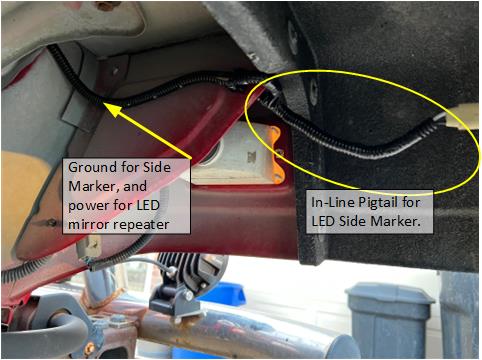

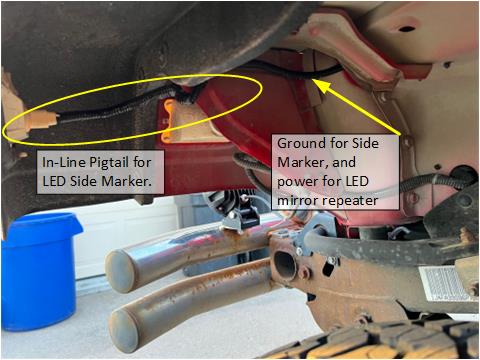

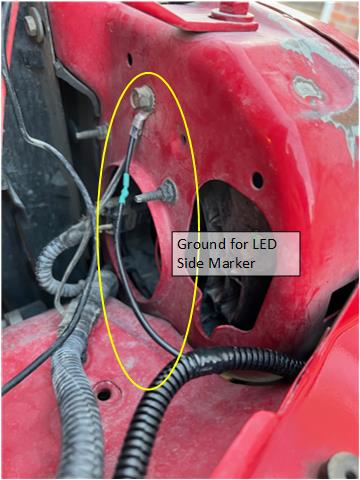

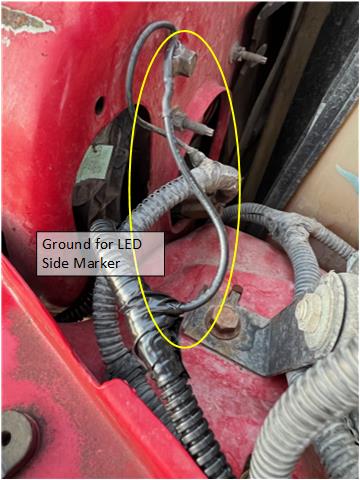

The entire side mirror could be removed from the vehicle and its wiring by 2 connectors at the mirror mounting bracket, and the grounding wire is under a mounting bolt for ground.

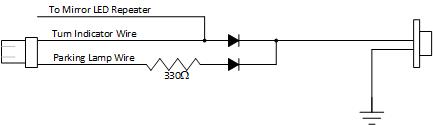

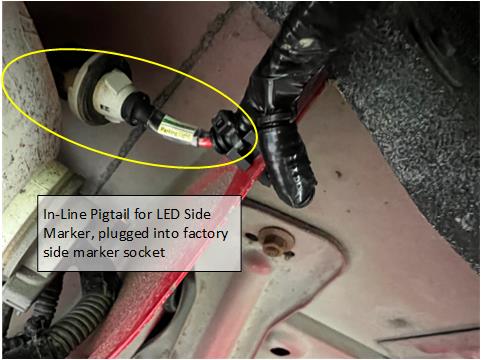

Wiring Power to Mirrors

I piggybacked power from the side fender turn indicator, and routed wiring into the engine compartment, and up to the cowl. The wiring I used to go from the cowl to the mirror itself was two wires in a PVC Jacket. The cowl pinches on the PVC jacket, but it doesn’t seem to cause an issue on the wires contained within. I heated the PVC jacket to fit into crevice between the body and windshield hinge.

Heated Mirrors

Timer control Board

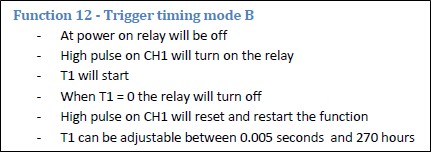

I wanted to mirror heaters to be on a timer similar to the rear defrost so it didn’t continually heat glass in cold weather if not necessary. I looked into some HELLA rear defrost relays, but I wasn’t thrilled at the price. I found a programmable timer relay board on Amazon that could be programmed for various functionality. I needed it to have the relay open when the board powered on (via keyed power circuit), relay closed when switch is pressed, and relay opens when the timer runs out. This ended up being Function 12.

The heating elements are rated at approximately 26W. The description is unclear if that is per element or total for the pair. Let’s assume it is per element, that would be 52W total. 52W / 12V = 4.3A. Also, my Jeep is usually around 13.2V while running (the only time I’d intend to run these) ∴ 52W / 13.2V = 3.93A. The timer board relay is rated for 10A.

Wiring for timed circuit and heating elements

I also wanted to be able to turn the timer off (in case of inadvertent activation). This took some extra thought, since I need to open a circuit when pressing a switch (typically closes a circuit). I suppose there are normally closed (NC) switches, but I couldn’t seem to find them on the wide array of Contura switches that I prefer to use. It then dawned on me that most automotive relays have an NC pin, that can be opened via power to coil side of relay providing a temporary ground break, thereby interrupting power to the board and resetting the timer. The wiring schematic below shows the final result.

Actual installation of this wiring and timer circuit to follow. I haven't had the chance to quite get there yet.

I wanted to add heated side mirrors to my Jeep, since I get freezing rain occasionally here in the Midwest and it’s not super easy to scrape off a thick layer of ice. They’re also handy for foggy/dewy mornings. I had seen a Toytoa Tacoma post about somebody using snowmobile grip heaters for DIY heated mirrors. And started to do some research. I figured I could add some LED turn signal repeaters on the mirrors while I was at it.

This information applies to the 2003-2006 style side mirrors. It will probably not apply to the older style side mirrors.

I ordered some used side mirrors from eBay and proceeded to disassemble them. I used a heat gun to soften the adhesive on the mirror glass and used trim tools to carefully slide in behind the glass and break the adhesive bond. I had to clean up the glass and the mirror mount of residual adhesive using a plastic scraper and mineral spirits. Then did a good cleaning with isopropyl alcohol to remove residue.

For the purposes of this write up, these are the terms I will use for the following parts.

Hole for LED turn signal repeater

I decided on ¾” round LED bullet markers for the turn signal repeater. I marked holes in the mirror housing and drilled holes. The LEDs I had just pop into the hole and stay in place with the grommet.

Hole for 90° barbed elbow

I wanted the wiring to look clean and tidy on the mirror, so I found some black hose barb elbows with ¼” NPT threads. I marked and drilled the mirror mounting brackets, and used a brass fitting with ¼” NPT threads to more or less tap the hole for the plastic threads. I used non-split loom over the hose barbs and black nylon hose clamps to keep it in place. This didn’t need to be water tight by any means, but provided very clean fit and finish. The non-split loom was zip tied to a zip tie anchor under the mirror arm, and routed up towards the mirror housing.

Holes for wire pass through

I needed to drill some holes through the mirror arm and the mirror mount. This would allow the wires to pass into the mirror housing. The hold would need to accommodate three wires (power for LED repeater, power for heating element, and a ground).

Apparently I didn't take many pictures while mounting the heating elements to the mirror glass. Sorry.

-EDIT- I found some pictures.

The heating element wires were routed through the mirror mount and into the mirror housing. Once the heating element was adhered to the mirror glass, I used 3M VHB tape to affix the glass to the mirror mount surface.

This tape is remarkably strong and has good temperature resistance and thermal expansion capability. I remember from an episode of I think Modern Marvels, that this is what was used to install the windows in the Burj Khalifa in Dubai to deal with the thermal expansion in the desert heat and cold.

Here's a bench test of the heated mirror. I place the mirror in my freezer for a bit, and then pulled it out to let it fog up and hooked it to a 12V battery.

Ground wires inside the mirror housing for the LED and heating element were connected to the ground wire exiting the housing.

I had some difficulty trying to get the three wires through the barbed elbow. It was just such an abrupt direction change, and the wires didn’t all want to change direction. I eventually did get everything through, used a little bit of wire pulling lubricant

The entire side mirror could be removed from the vehicle and its wiring by 2 connectors at the mirror mounting bracket, and the grounding wire is under a mounting bolt for ground.

Wiring Power to Mirrors

I piggybacked power from the side fender turn indicator, and routed wiring into the engine compartment, and up to the cowl. The wiring I used to go from the cowl to the mirror itself was two wires in a PVC Jacket. The cowl pinches on the PVC jacket, but it doesn’t seem to cause an issue on the wires contained within. I heated the PVC jacket to fit into crevice between the body and windshield hinge.

Heated Mirrors

Timer control Board

I wanted to mirror heaters to be on a timer similar to the rear defrost so it didn’t continually heat glass in cold weather if not necessary. I looked into some HELLA rear defrost relays, but I wasn’t thrilled at the price. I found a programmable timer relay board on Amazon that could be programmed for various functionality. I needed it to have the relay open when the board powered on (via keyed power circuit), relay closed when switch is pressed, and relay opens when the timer runs out. This ended up being Function 12.

The heating elements are rated at approximately 26W. The description is unclear if that is per element or total for the pair. Let’s assume it is per element, that would be 52W total. 52W / 12V = 4.3A. Also, my Jeep is usually around 13.2V while running (the only time I’d intend to run these) ∴ 52W / 13.2V = 3.93A. The timer board relay is rated for 10A.

Wiring for timed circuit and heating elements

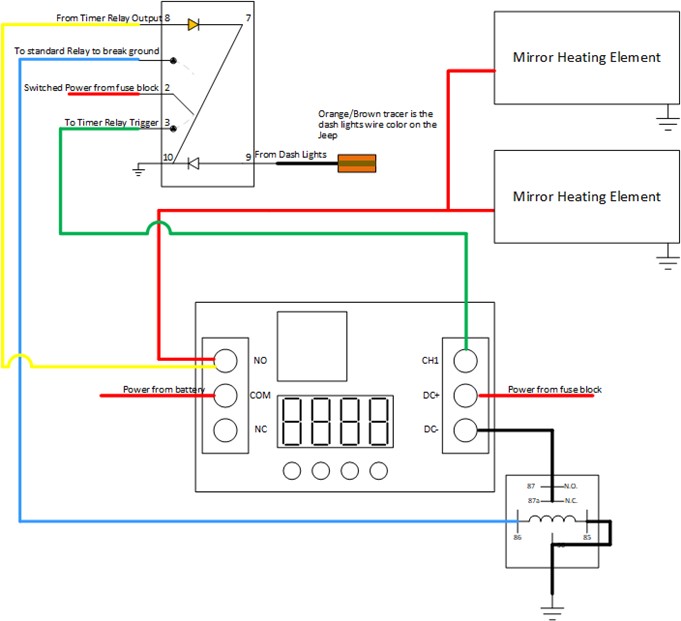

I also wanted to be able to turn the timer off (in case of inadvertent activation). This took some extra thought, since I need to open a circuit when pressing a switch (typically closes a circuit). I suppose there are normally closed (NC) switches, but I couldn’t seem to find them on the wide array of Contura switches that I prefer to use. It then dawned on me that most automotive relays have an NC pin, that can be opened via power to coil side of relay providing a temporary ground break, thereby interrupting power to the board and resetting the timer. The wiring schematic below shows the final result.

- The timer relay board has keyed power into the DC+ terminal. It’s ground wire is routed from DC- to the load side of a standard 5-pin relay landed on pin 87a the NC pin.

- The switch is a Contura (On) – Off – (On). It is momentary both up and down. I bought one that didn’t have illumination (since I couldn’t find the LED combo I wanted anyway) and switch the momentary internals into an illuminated Contura switch I had that was not momentary, and switch one of the LEDs for color preference

- Pin 2 gets keyed power

- Pin 3 (green) sends 12V to the timer relay CH1 pin

- Pin 1 (blue) sends 12V to the coil side of the standard 5-pin relay

- This opens the relay, and therefore ground connection to the timer board

- Pin 8 receives 12V from the timer board when the timer is active to illuminate an amber LED (like most rear defrost switches)

- Pin 7 and Pin 10 are grounded for the switch’s LEDs (I swapped an LED color in the switch and managed to put the LED in backwards so had to switch the wiring polarity)

- https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwjc8sOgr_mDAxWqJzQIHUoPCPsQFnoECBkQAQ&url=https://www.thehulltruth.com/marine-electronics-forum/346417-replace-bulb-led-contura-switch.html&usg=AOvVaw3ypBp--Wt5an0XOiNJKgZT&opi=89978449

- Pin 9 is power from the dash lights circuit, to illuminate the switch when dash lights are powered.

- Power from the battery is wired into the COM terminal on the timer board

- The heating elements are wired into the normally open (NO) terminal

- The amber LED on the switch is also power from the NO terminal .

Actual installation of this wiring and timer circuit to follow. I haven't had the chance to quite get there yet.

Last edited: