You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

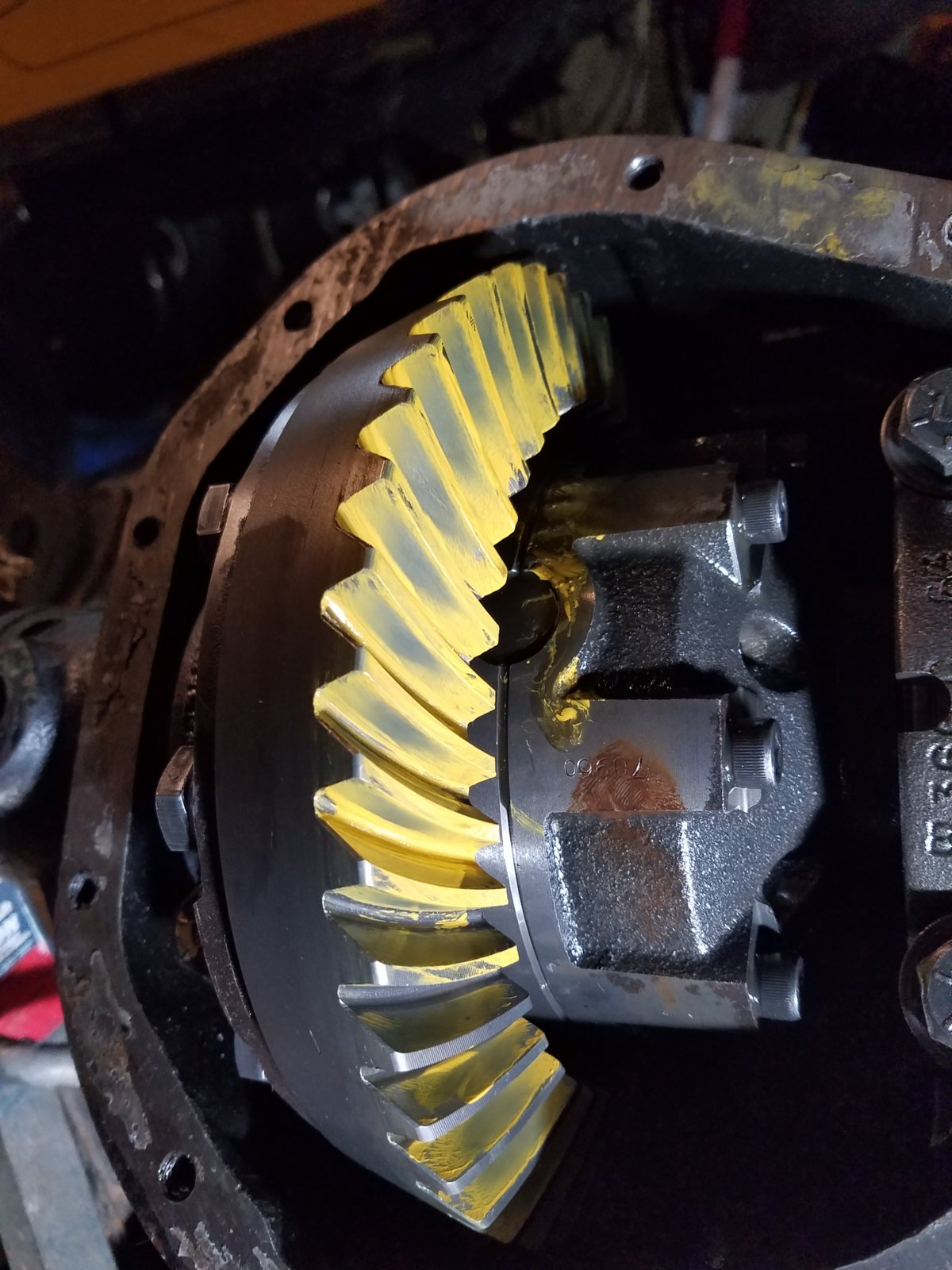

Does this gear mesh pattern look okay?

- Thread starter Alex0413

- Start date

I would add to the depth. What is the backlash?

Backlash is at 7, how much depth would you add to try and center the pattern a little better on the drive side?

Last edited:

It's totally runable, but try adding like .003 to pinion depth, see what it does. I like a deeper pattern personally. Also, mix in a couple drops of gear oil to your paint, and more pressure on the pinion when you are turning.

Awesome post . I'm going to use that myself the next time gearing comes up.It's totally runable, but try adding like .003 to pinion depth, see what it does. I like a deeper pattern personally. Also, mix in a couple drops of gear oil to your paint, and more pressure on the pinion when you are turning.

I screwed my gears up....man it is such an intense job.

You guys that understand them have my respect...and right now a guy that understands them is about to have my money.

Gears are no joke.

When you are doing gears, I've found that making slip bearings, running zero preload on carrier bearings (so you can slip in in and out) and cutting a piece of tube to simulate a yoke makes the job about 25% of the time. But bearings are spendy, it's a give or take on time versus money for sure. I'm lucky I've done enough to have slip bearings for Dana 30, Dana 44, Dana 60, and Ford 10.50. They go pretty quick, even for an amateur.

Watch the videos Karl Jantz put up on Youtube, they helped me get faster for sure.

Watch the videos Karl Jantz put up on Youtube, they helped me get faster for sure.

It's totally runable, but try adding like .003 to pinion depth, see what it does. I like a deeper pattern personally. Also, mix in a couple drops of gear oil to your paint, and more pressure on the pinion when you are turning.

So it is an acceptable pattern? But I could possibly chase perfection my slightly centering it more with a little more pinion depth?

When you are doing gears, I've found that making slip bearings, running zero preload on carrier bearings (so you can slip in in and out) and cutting a piece of tube to simulate a yoke makes the job about 25% of the time. But bearings are spendy, it's a give or take on time versus money for sure. I'm lucky I've done enough to have slip bearings for Dana 30, Dana 44, Dana 60, and Ford 10.50. They go pretty quick, even for an amateur.

Watch the videos Karl Jantz put up on Youtube, they helped me get faster for sure.

Having the proper bearing puller so I could get the factory shim stacks to start with and make setup bearings made this a lot easier! Using a pipe to simulate the yoke is genius!!!

Personally I would add a touch more pinion shim to see what it does.So it is an acceptable pattern? But I could possibly chase perfection my slightly centering it more with a little more pinion depth?

Personally I would add a touch more pinion shim to see what it does.

cool I'll add 003 and see where it gets me.

I did thin the paint with gear oil and added as much pressure as I could to the ring gear and ran a pattern at a different spot:

Better. When changing depth it is advisable to go beyond what you may think you need and come back as necessary. So if you think it needs .005, go .010. If then too deep you know that the .005-.008 is where you need to be and adjust accordingly. I would add to what you have now and see if where that puts you.

Better. When changing depth it is advisable to go beyond what you may think you need and come back as necessary. So if you think it needs .005, go .010. If then too deep you know that the .005-.008 is where you need to be and adjust accordingly. I would add to what you have now and see if where that puts you.

So going through my shims from the master install kit and after talking with Yukon, it seems that they only included shims to go under the pinion race!!!!!! That's a PITA to drive that in and out! I think I might need to order some pinion shims that go under the bearing on the pinion. Have you experienced this?

Subbed, looking to do this kind of stuff now that I have a garage in which I have room to move around in without constantly bumping into random crap.

Ditto. Whenever I get to this point this will be one of many resources I come back to. The contributors here share some of those small, esoteric sort of tips that can be the key to success.

That last one I would run no problem. Just make sure it looks like that at places all the way around, carriers can have runout sometimes.

That last one I would run no problem. Just make sure it looks like that at places all the way around, carriers can have runout sometimes.

X2. On the couple I have been around they dialed them in like this, then painted the whole carrier and ran it to confirm.

Shims behind the race is the normal place for Dana diffs. That is why you want to use a brass drift to drive the race out.