So I purchased a '00 Sport (4.0, 5spd) about a month back, first time jeep owner. When I purchased it I noticed the oil pressure gauge only reads 10ish psi at all times. Cold start, warm start, cold day, hot day, regardless of RPM...10psi. After doing some research I saw the issues with the sensor working fine for a bit then just dropping to 0. I also found that my gauge should still be an actual functioning gauge (i.e. the gauge should move depending on the above variables), as they didn't change the PCM programing until '02ish to make it a "dummy gauge". I know the wiring to the sensor is good as if I unplug it, it reads 0 and the "check gauges" light comes on. Before throwing money at it, I figured I'd ask here first and see if anyone had this issue, or may have some suggestions. I think I'm going to pull the sensor, give it a good spray of parts cleaner and see what that yields. Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

10psi oil pressure?

- Thread starter SouthernTJ2000

- Start date

Standard answer is to put a mechanical gauge on it and see what readings you get directly off the engine, w/o any influence from the PCM or other electronics.

So this has turned into quiet the fiasco. Went to pull it off and realized I don’t have the proper socket size. Okay, I’ll get a crescent in there. To hell with that, I’m not taking this off at a 1/16 of a turn at a time. Research the ole interwebs, 1-1/16” socket it is. Ordered. Received. WTF, just a tad to small….ugghhh. More research. Okay, 1-3/16”. Ordered. Received. Just a tad to big?!?!?! You sorry….. Fine, I’ll do it with a crescent. Well, that sucked, but its off. Put the new master craft one on, that actually utilized the 1-1/16” socket…score. I know, I know, go with a genuine Mopar. Anyway, fire it up, BAM…works like a charm. Kill it, go to bed. Wake up the next morning to go to work. Fire it up, works great. 15 minutes down the road come to a stop, “check gauges” light comes on and 0 oil pressure. Take off, light goes out and I have oil pressure…..ugghhhh. Rinse and repeat these results all the way to work. Guess I’ll be taking this sensor back to the parts house for a refund and order the Mopar one.

Last edited:

There is a special oil pressure sensor socket you can get from the parts store, but other things can work in a pinch.

Much has been said about the Mopar sensor vs other brands. I've had this problem with both my 97's. For mine, changing the sensor didn't do anything (I went with a Standard Motor Products), so I changed the pump with a new Melling. Never had a low pressure problem again. Seems like it actually was a pressure problem and not a sensor problem since the new pump fixed it.

On my daughter's, I put in the same new sensor but nothing changed. This time I'm going to put a mechanical gauge on it first to verify the pressure fluctuations (which I should've done on mine). This is my recommendation to you.

I've also heard that some gunk can get into the port and cause issues with the reading.

Much has been said about the Mopar sensor vs other brands. I've had this problem with both my 97's. For mine, changing the sensor didn't do anything (I went with a Standard Motor Products), so I changed the pump with a new Melling. Never had a low pressure problem again. Seems like it actually was a pressure problem and not a sensor problem since the new pump fixed it.

On my daughter's, I put in the same new sensor but nothing changed. This time I'm going to put a mechanical gauge on it first to verify the pressure fluctuations (which I should've done on mine). This is my recommendation to you.

I've also heard that some gunk can get into the port and cause issues with the reading.

There is a special oil pressure sensor socket you can get from the parts store, but other things can work in a pinch.

Much has been said about the Mopar sensor vs other brands. I've had this problem with both my 97's. For mine, changing the sensor didn't do anything (I went with a Standard Motor Products), so I changed the pump with a new Melling. Never had a low pressure problem again. Seems like it actually was a pressure problem and not a sensor problem since the new pump fixed it.

On my daughter's, I put in the same new sensor but nothing changed. This time I'm going to put a mechanical gauge on it first to verify the pressure fluctuations (which I should've done on mine). This is my recommendation to you.

I've also heard that some gunk can get into the port and cause issues with the reading.

So I did order the 1-1/16" & 1-3/16" oil pressure socket. Made install of the new one so much easier. I did clean the block port while I had the sensor off. I'm going to pick up a oil pressure gauge to check it that way before replacing this sensor. On my long list of maintenance is a new RMS. While I'm in there I planned on replacing the oil pump, jeep has 154K on it. Looks like I might be tackling this sooner than later.

Yeah, mine had 185k, daughters has 240k. The 4.0 is a workhorse, but everything wears out eventually.

Yeah, mine had 185k, daughters has 240k. The 4.0 is a workhorse, but everything wears out eventually.

Quick question. I'm assuming there is a oil pump rod that runs from the distributor to the pump? Was it easy enough to just slide it back in from the bottom side, or did you need to remove the distributor? Mines an '00 so it has the electric distributor thing, however I assume it works the same way.

Quick question. I'm assuming there is a oil pump rod that runs from the distributor to the pump? Was it easy enough to just slide it back in from the bottom side, or did you need to remove the distributor? Mines an '00 so it has the electric distributor thing, however I assume it works the same way.

I don't remember if you NEED to remove the distributor....I don't think you do. I did, which is why I don't remember if it's required. The oil pump has a slotted shaft at the top which matches with the bottom end of the distributor (looks like a flathead screw driver). Those two parts mate. Let me grab a pic real fast (brb).

Now WHY I removed the distributor was because I read many places about the need to prime the oil pump first with a drill or some such until you could feel some pressure build up. I did that for a LONG time and it never felt like it did anything, contrary to what I read everywhere. So I put the dizzy back in and when I fired it up I immediately had pressure.

I vaguely recall that you can somehow pack the pump with petroleum jelly in lieu of priming it, but I can neither confirm nor deny.

This is the distributor end, looks like a screwdriver.

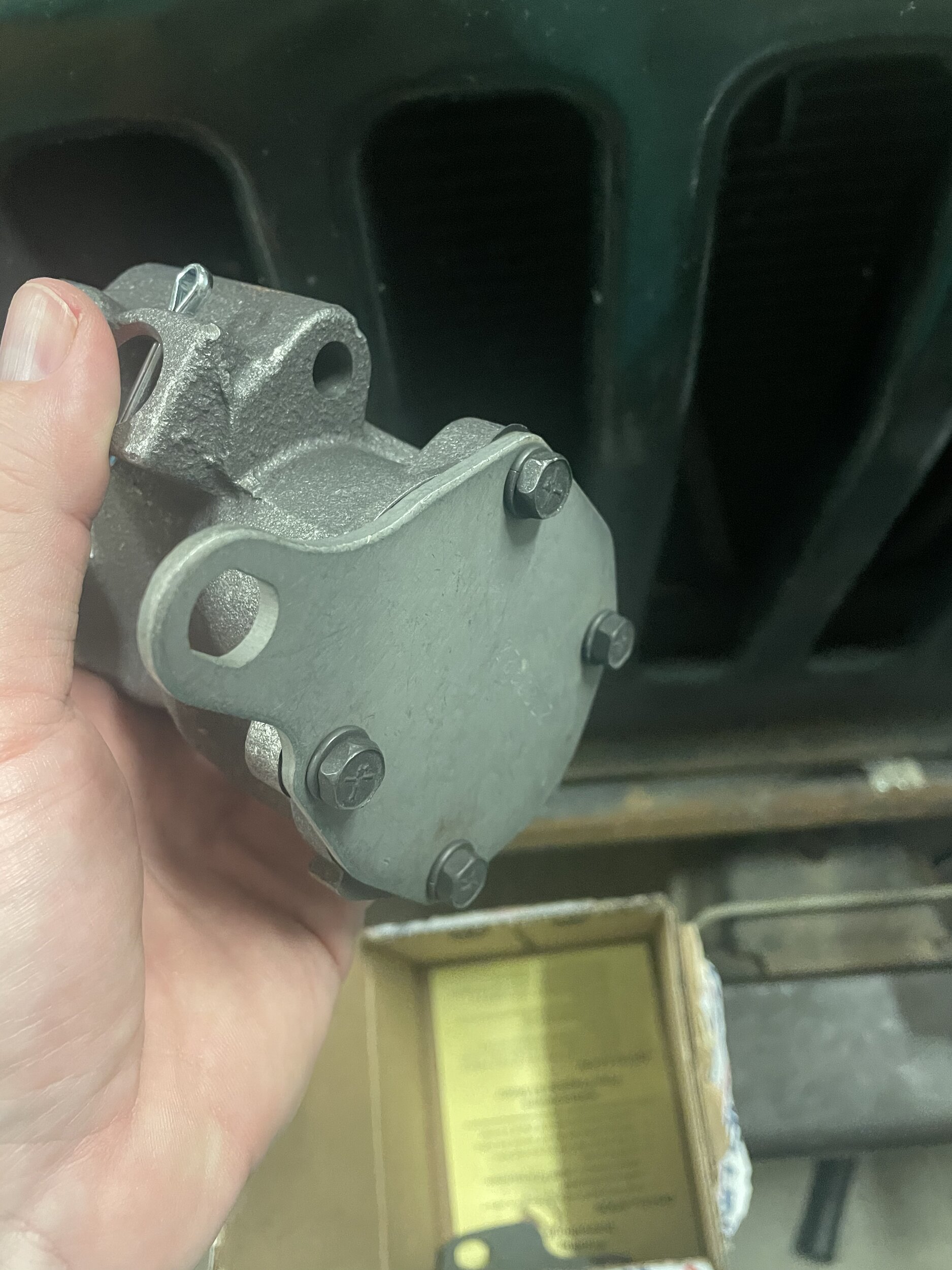

Then the pump has this “receiving” slot.

And then I believe the priming “hack” involves removing this plate, but I need to re-find that thread.

Then the pump has this “receiving” slot.

And then I believe the priming “hack” involves removing this plate, but I need to re-find that thread.

This is the distributor end, looks like a screwdriver.

Then the pump has this “receiving” slot.

And then I believe the priming “hack” involves removing this plate, but I need to re-find that thread.

Greatly appreciated!!!

Found this, which is what I recall reading when I did mine......and then basically ignored everything because YOLO? But like I said, I had pressure immediately when I started it up. Priming via drill did not work as advertised (it didn't get hard to spin), although I didn't think to check the gauge itself. If/when I do this again I'll probably also use a mechanical gauge to see if it's primed.

https://www.jeepforum.com/threads/forgot-to-prime-new-oil-pump-question.729734/

https://www.jeepforum.com/threads/forgot-to-prime-new-oil-pump-question.729734/