Okay so first off I want to preface that this was my first attempt at a DIY Highline, purchasing an actual kit to use actual Highline fenders is definitely much easier but my brother wanted to keep the Jeep look as well as not spend 1000+ dollars on the proper fenders, also this isn't a complete write-up as my brother did some of the work but didn't document any of it so Ill do my best to fill the gaps as best as I can.

The first step should feel a bit obvious but remove all the bolts holding the fender to both the tub and grill so it is one free entity, as well as everything connected to the fender.

The bottom bolt hole on the grill can be reused, the other holes need to be re-drilled, this was our first test fit, you can see just how much clearance a project like this can create. I feel now is a great time to talk about the why of this project. My brother uses his Jeep for daily driving and occasional camping trips. It doesn't see many hardcore trails and he really likes the looks of 35s. He has a roof rack and RTT for said adventures. At the current lift height of approximately 2in, he barely, and I mean almost touches the entrances to the parking garages on campus so lifting it was an automatic no, he also does not want to drop tire size so I suggested we try to highline it.

To get the inner fender to go all the way up in the front, you have to grind the lip behind the headlight, we used a Dremel with a rotary bit and cut-off wheel.

While working on the front we clamped the rear of the fender to the tub to locate it.

We started by using the bottom bolt and tightened that down, I didn't mention this but you also need to pull your headlights to access the holes you are drilling into the grill to get and nut and fender washer on.

Before we get too far, make sure you cut this slot in the fender brace, this will give the fender enough flex to bend around, this is very important as you won't be able to get it to bend without this cut.

The next thing you want to do is drill a large enough hole into the grill using the fender holes as your reference guide. After drilling the second hole, using a longer bolt and large fender washers on both sides, tighten the bolt so it sucks the fender in as close as you can to the grill. This is where things start to get a bit tricky as its very easy to stretch the metal and break the paint, this part didn't turn out perfect for us but from what I understand this is a pretty common issue a lot of people run into.

The last bolt is the farthest stretch, you can kind of see where the fender stretched in this picture.

As for hardware, this is what you are looking for, a long enough bolt to bridge the gap between the grill and fender and the largest fender washers you can find to have the most surface area as possible.

This is what the grill should look like in term of hole locations.

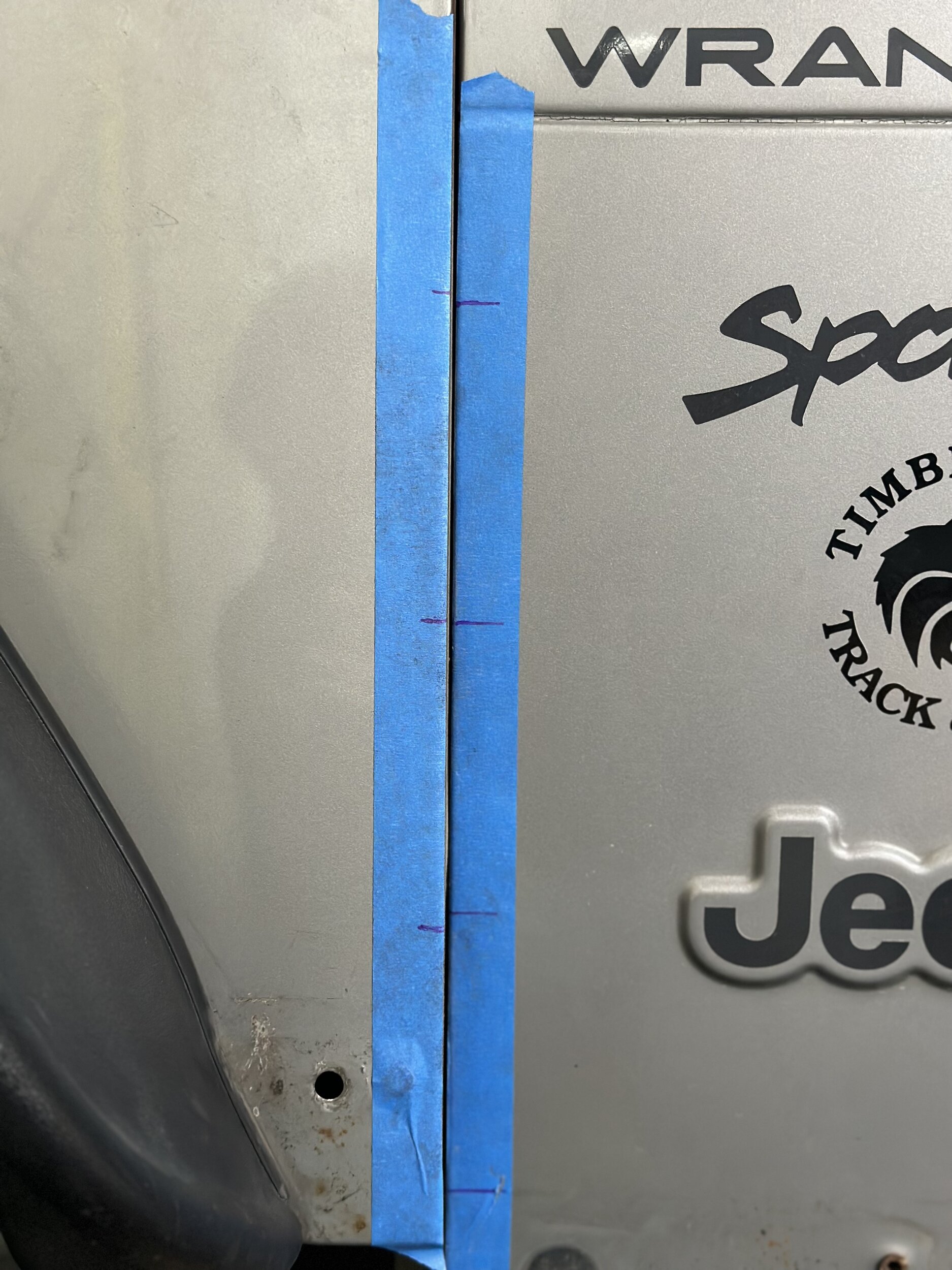

The next step is to completely pull your fender and get ready because this thing can be a bit awkward because you will probably have to take it off and put it back on 3-4 times. with the fender take a piece of painter's tape and put it at the full height of the fender next to the edge of the tub, mark your factory holes on your tub on the tape.

Now you want to reinstall your fenders, set the rear height to be flush with the top body line, and apply another piece of masking tape to the fender, the bottom hole is not usable if I remember correctly, as for the lines, please make sure you mark them correctly or it with be a major pain to fix, yes I caught this before drilling but those lines not even close and I don't remember how they ended up so weird, but I did get it correct before drilling.

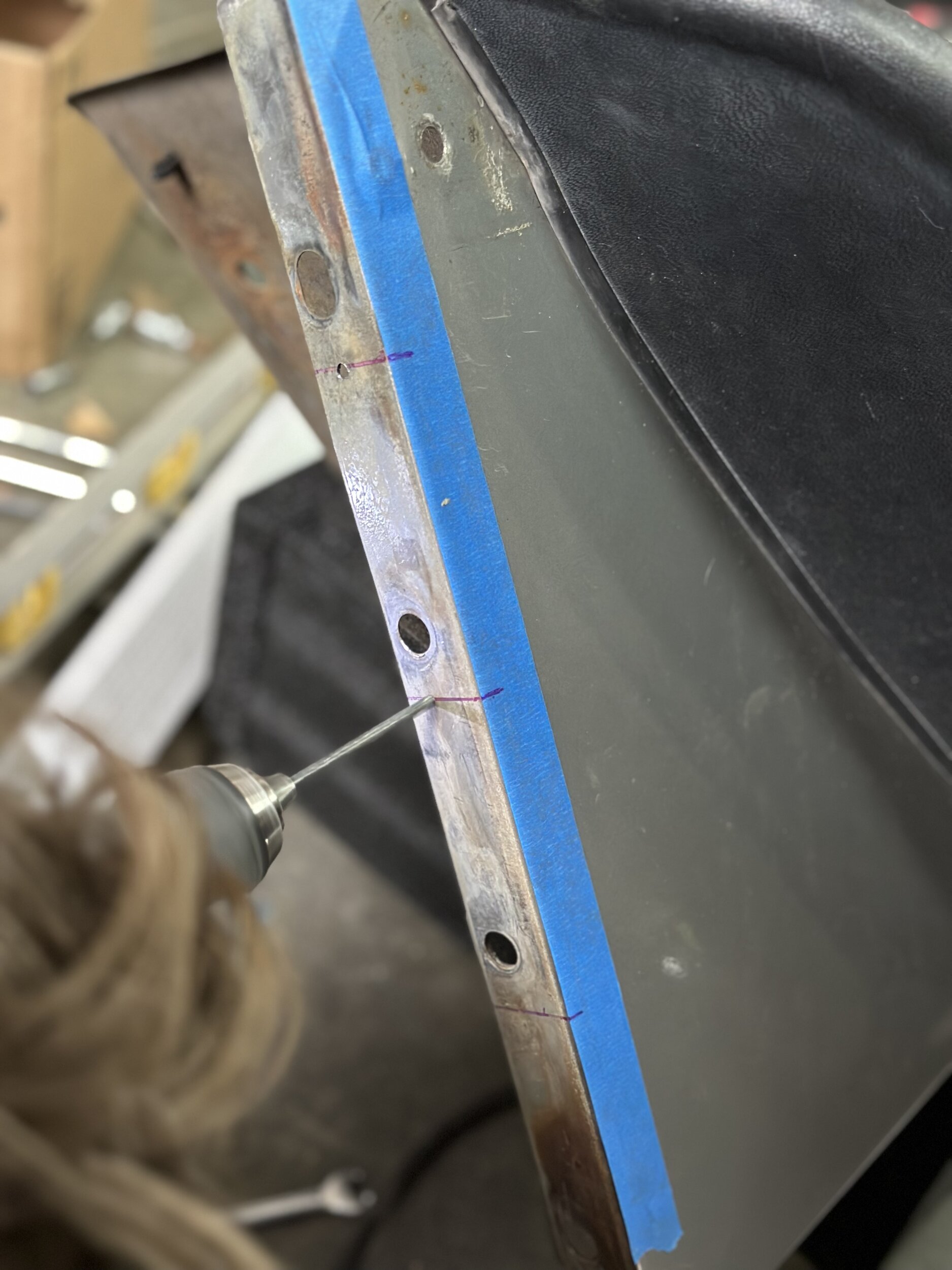

After you are happy with your lines, pull the fender again and use a speed square to transfer the lines to the inside lip of the fender.

After you've transferred your lines, drill pilot holes in line with the old holes in their new positions, please don't be like us and actually measure it instead of eyeballing it, I am amazed looking back on it that everything lined up. For some adjustability, I did end up ovaling out the holes a bit just so that we could position them as perfectly as possible.

We used a step bit to enlarge the pilot holes, this worked pretty good.

Finally, you need to cut a bit of the metal from the bottom usable hole on the backside to get a bolt in, this concludes the work you have to bolt the fenders up, with the fenders bolted in and that slot cut into the front brace, you should be able to bend the fenders almost all the way down to flat, we weren't able to get it all the way be a lot closer than what it looks like when you first bolt everything together.

With everything said and done, this is how your new highline fender should look.

Now unfortunetely most of the rest of the project was completed without much documentation, but fortunately I should be able to use both the information from Higherground4x4 and the few pictures I have to finish out this thread. We retained both brackets because they added too much rigidity to just ignore, Its really as simple as cutting on the line in the picture above for both sides.

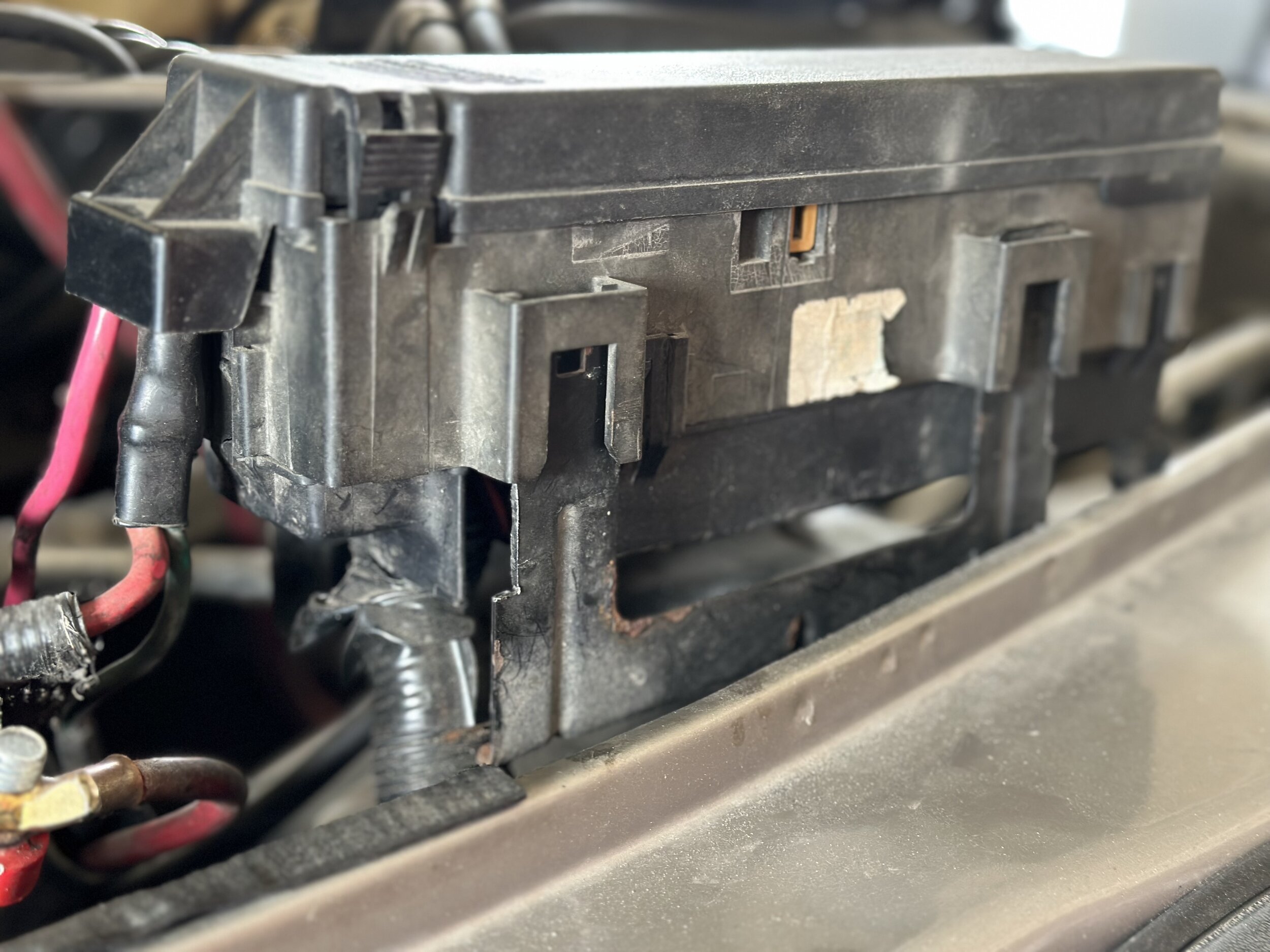

To fit the fuse box, notch it like the picture above so that it can slid further down the mounting bracket.

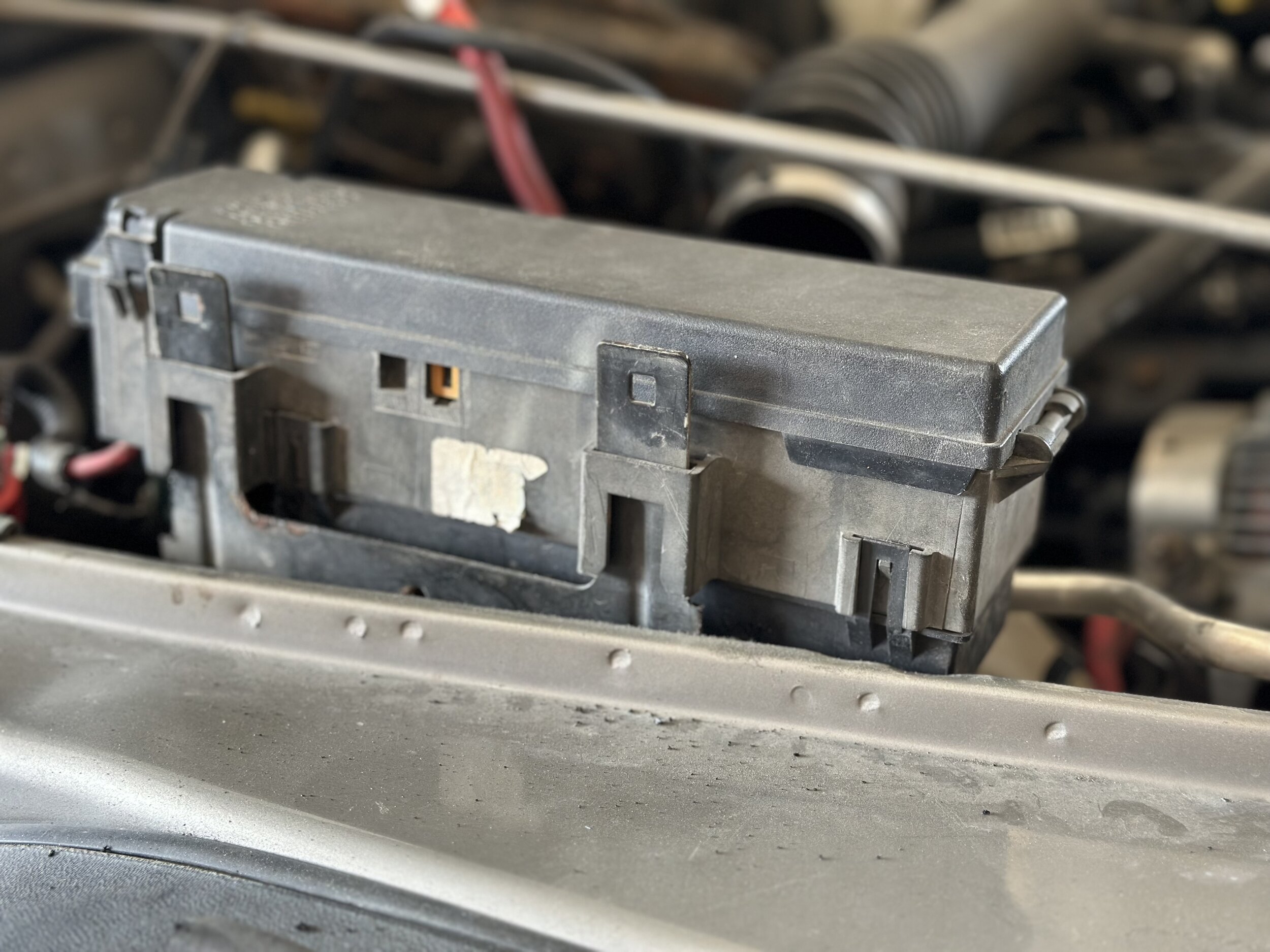

This should be the finished product for your fuse box.

I can only attach 20 photos per post, so I will be posting this and then adding the rest afterward.

Also, I accidentally added this to the general forum instead of the how-to, I don't know how to move it so if @Chris or anyone else that knows how to move it to the how-to section of the forum?

The first step should feel a bit obvious but remove all the bolts holding the fender to both the tub and grill so it is one free entity, as well as everything connected to the fender.

The bottom bolt hole on the grill can be reused, the other holes need to be re-drilled, this was our first test fit, you can see just how much clearance a project like this can create. I feel now is a great time to talk about the why of this project. My brother uses his Jeep for daily driving and occasional camping trips. It doesn't see many hardcore trails and he really likes the looks of 35s. He has a roof rack and RTT for said adventures. At the current lift height of approximately 2in, he barely, and I mean almost touches the entrances to the parking garages on campus so lifting it was an automatic no, he also does not want to drop tire size so I suggested we try to highline it.

To get the inner fender to go all the way up in the front, you have to grind the lip behind the headlight, we used a Dremel with a rotary bit and cut-off wheel.

While working on the front we clamped the rear of the fender to the tub to locate it.

We started by using the bottom bolt and tightened that down, I didn't mention this but you also need to pull your headlights to access the holes you are drilling into the grill to get and nut and fender washer on.

Before we get too far, make sure you cut this slot in the fender brace, this will give the fender enough flex to bend around, this is very important as you won't be able to get it to bend without this cut.

The next thing you want to do is drill a large enough hole into the grill using the fender holes as your reference guide. After drilling the second hole, using a longer bolt and large fender washers on both sides, tighten the bolt so it sucks the fender in as close as you can to the grill. This is where things start to get a bit tricky as its very easy to stretch the metal and break the paint, this part didn't turn out perfect for us but from what I understand this is a pretty common issue a lot of people run into.

The last bolt is the farthest stretch, you can kind of see where the fender stretched in this picture.

As for hardware, this is what you are looking for, a long enough bolt to bridge the gap between the grill and fender and the largest fender washers you can find to have the most surface area as possible.

This is what the grill should look like in term of hole locations.

The next step is to completely pull your fender and get ready because this thing can be a bit awkward because you will probably have to take it off and put it back on 3-4 times. with the fender take a piece of painter's tape and put it at the full height of the fender next to the edge of the tub, mark your factory holes on your tub on the tape.

Now you want to reinstall your fenders, set the rear height to be flush with the top body line, and apply another piece of masking tape to the fender, the bottom hole is not usable if I remember correctly, as for the lines, please make sure you mark them correctly or it with be a major pain to fix, yes I caught this before drilling but those lines not even close and I don't remember how they ended up so weird, but I did get it correct before drilling.

After you are happy with your lines, pull the fender again and use a speed square to transfer the lines to the inside lip of the fender.

After you've transferred your lines, drill pilot holes in line with the old holes in their new positions, please don't be like us and actually measure it instead of eyeballing it, I am amazed looking back on it that everything lined up. For some adjustability, I did end up ovaling out the holes a bit just so that we could position them as perfectly as possible.

We used a step bit to enlarge the pilot holes, this worked pretty good.

Finally, you need to cut a bit of the metal from the bottom usable hole on the backside to get a bolt in, this concludes the work you have to bolt the fenders up, with the fenders bolted in and that slot cut into the front brace, you should be able to bend the fenders almost all the way down to flat, we weren't able to get it all the way be a lot closer than what it looks like when you first bolt everything together.

With everything said and done, this is how your new highline fender should look.

Now unfortunetely most of the rest of the project was completed without much documentation, but fortunately I should be able to use both the information from Higherground4x4 and the few pictures I have to finish out this thread. We retained both brackets because they added too much rigidity to just ignore, Its really as simple as cutting on the line in the picture above for both sides.

To fit the fuse box, notch it like the picture above so that it can slid further down the mounting bracket.

This should be the finished product for your fuse box.

I can only attach 20 photos per post, so I will be posting this and then adding the rest afterward.

Also, I accidentally added this to the general forum instead of the how-to, I don't know how to move it so if @Chris or anyone else that knows how to move it to the how-to section of the forum?