After having a bad head on in a loaded van in 2013 I began looking for better work ideas and found contractor Ron Paulk out of Anacortes, Washington on line- he had a video on a great trailer set up so I decided to go that direction-

Here is where I am today :

Image one is during a typical work day - everything is designed for easy access and fast set up- the miter saw is cordless and stays put -

First thing was multiple coats of spar varnish inside the trailer, and a traction additive in the final tailgate coat - then added screws to the floor from underneath and screws all in the interior plywood to unify it better -

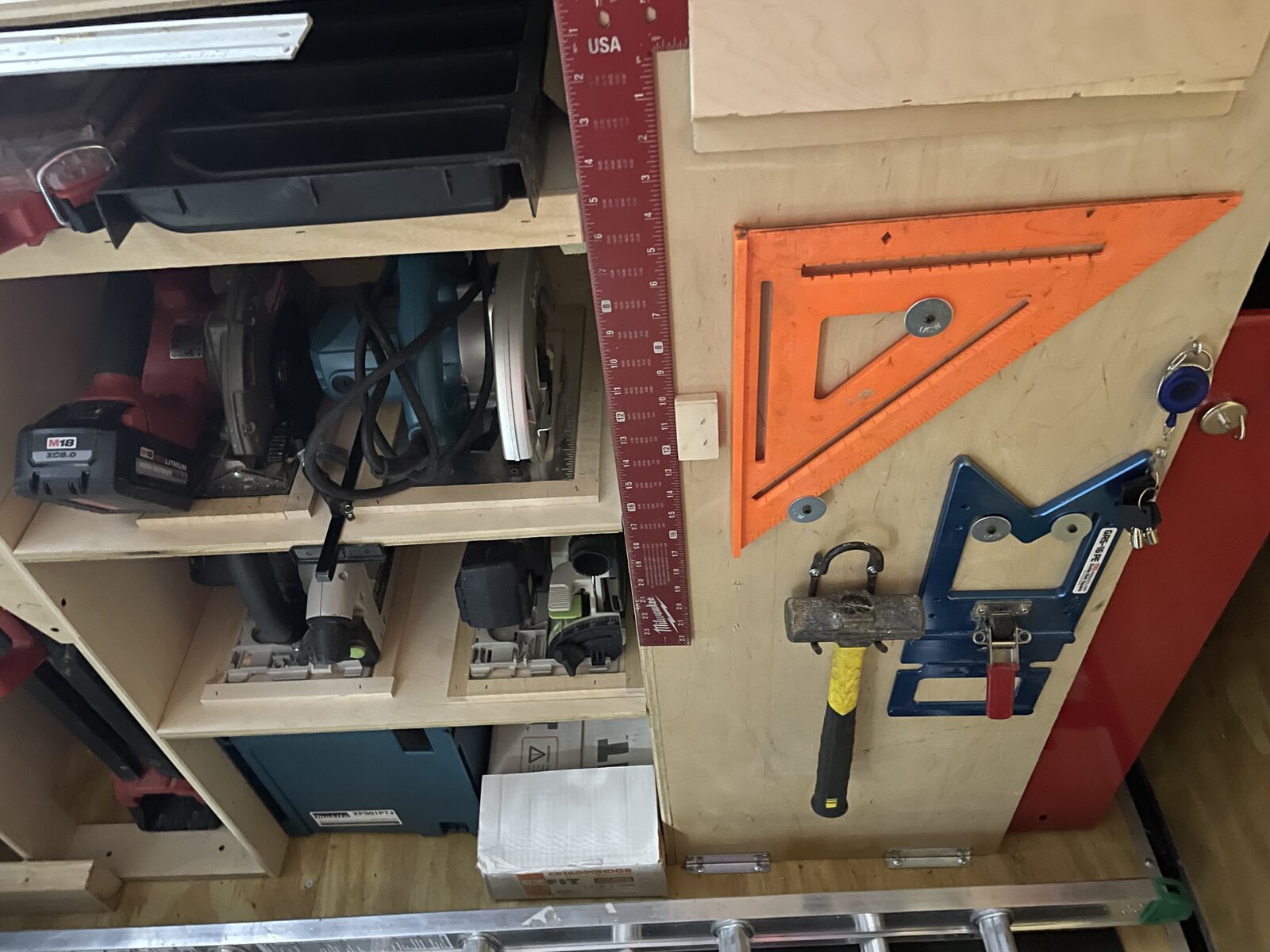

Tool compartments- all tools are out of the case- I want the tool in my hand -

Marking tools by the back door for a fast grab - the red toolbox in the first image is behind these with all gun nails

Ladders are in the front - things we do not use as frequently are toward the front, or things you only grab once a day like tool belts.

The hoses and cords go out the side door, compressor is behind the air tool mounted in, tank dranks out the floor. This 10 gauge 100 foot cord is the shore cord that runs everything.

The air is plumbed and the big hole is to drain the tank-It has a hose and goes out the floor of the trailer.

Stains are are all readable

Anything that needs to stay out of the way has a retractable tether

This led light has a built in battery that is plugged in to the trailer for light 24/7

All the chargers are wired in - we have 2 main platforms- Dewalt and Milwaukee.

Clamps act as fences for tools during transport and stay handy

Caulk is below the miter saw outfeed

The hot batteries stay handy above the saw , first aid kit is docked below it

The miter saw has an extruded x track with adjustable stops

Cords are real rubber for pliability and hoses polyurethane- the paslode below may be on the way out- the red bin below them is screws to the table and has all the common screws we use-

The trailer is based on lean principles- construction is just manufacturing- done remotely, with lots of variation- so you have to save time where you can to give the challenges you run into the time they need.

Our main rule is nothing has to be moved to get to anything else- this creates shuffling which leads to chaos.

Secondly is we keep complimentary tools together.

Third is frequency of use dictates the layout.

We carry tools to work on tools.

The black boxes have all the hand tools and supplies and although they lock they have neobendium magnets that pull them shut. More magnets are on order- so handy.

I started this at 47 and have learned more in the last 8 years about tool and supply management than all the years before- the trailer stays this neat all the time.

Another truth I’ve learned is the better the system you have is the less you notice it-

Once it is working, your system will tell you if something is missing- it really will.

Another thing this does is prevents frustration- it makes work a joy. This is huge, because mood affects productivity.

In my opinion the average tradesperson works far harder and earns less than they are capable of.

Every day I go to work and know exactly what I have and what I don’t have- which is just as important.

All of this pays for itself- and the only downside is I practically can’t install a light switch cover without it- I simply no longer want to work any other way. It makes it that much easier.

Thanks for reading my thread, and please share any workshop or worksite tips you have - I’m always looking for new ideas.

Here is where I am today :

Image one is during a typical work day - everything is designed for easy access and fast set up- the miter saw is cordless and stays put -

First thing was multiple coats of spar varnish inside the trailer, and a traction additive in the final tailgate coat - then added screws to the floor from underneath and screws all in the interior plywood to unify it better -

Tool compartments- all tools are out of the case- I want the tool in my hand -

Marking tools by the back door for a fast grab - the red toolbox in the first image is behind these with all gun nails

Ladders are in the front - things we do not use as frequently are toward the front, or things you only grab once a day like tool belts.

The hoses and cords go out the side door, compressor is behind the air tool mounted in, tank dranks out the floor. This 10 gauge 100 foot cord is the shore cord that runs everything.

The air is plumbed and the big hole is to drain the tank-It has a hose and goes out the floor of the trailer.

Stains are are all readable

Anything that needs to stay out of the way has a retractable tether

This led light has a built in battery that is plugged in to the trailer for light 24/7

All the chargers are wired in - we have 2 main platforms- Dewalt and Milwaukee.

Clamps act as fences for tools during transport and stay handy

Caulk is below the miter saw outfeed

The hot batteries stay handy above the saw , first aid kit is docked below it

The miter saw has an extruded x track with adjustable stops

Cords are real rubber for pliability and hoses polyurethane- the paslode below may be on the way out- the red bin below them is screws to the table and has all the common screws we use-

The trailer is based on lean principles- construction is just manufacturing- done remotely, with lots of variation- so you have to save time where you can to give the challenges you run into the time they need.

Our main rule is nothing has to be moved to get to anything else- this creates shuffling which leads to chaos.

Secondly is we keep complimentary tools together.

Third is frequency of use dictates the layout.

We carry tools to work on tools.

The black boxes have all the hand tools and supplies and although they lock they have neobendium magnets that pull them shut. More magnets are on order- so handy.

I started this at 47 and have learned more in the last 8 years about tool and supply management than all the years before- the trailer stays this neat all the time.

Another truth I’ve learned is the better the system you have is the less you notice it-

Once it is working, your system will tell you if something is missing- it really will.

Another thing this does is prevents frustration- it makes work a joy. This is huge, because mood affects productivity.

In my opinion the average tradesperson works far harder and earns less than they are capable of.

Every day I go to work and know exactly what I have and what I don’t have- which is just as important.

All of this pays for itself- and the only downside is I practically can’t install a light switch cover without it- I simply no longer want to work any other way. It makes it that much easier.

Thanks for reading my thread, and please share any workshop or worksite tips you have - I’m always looking for new ideas.

Last edited: