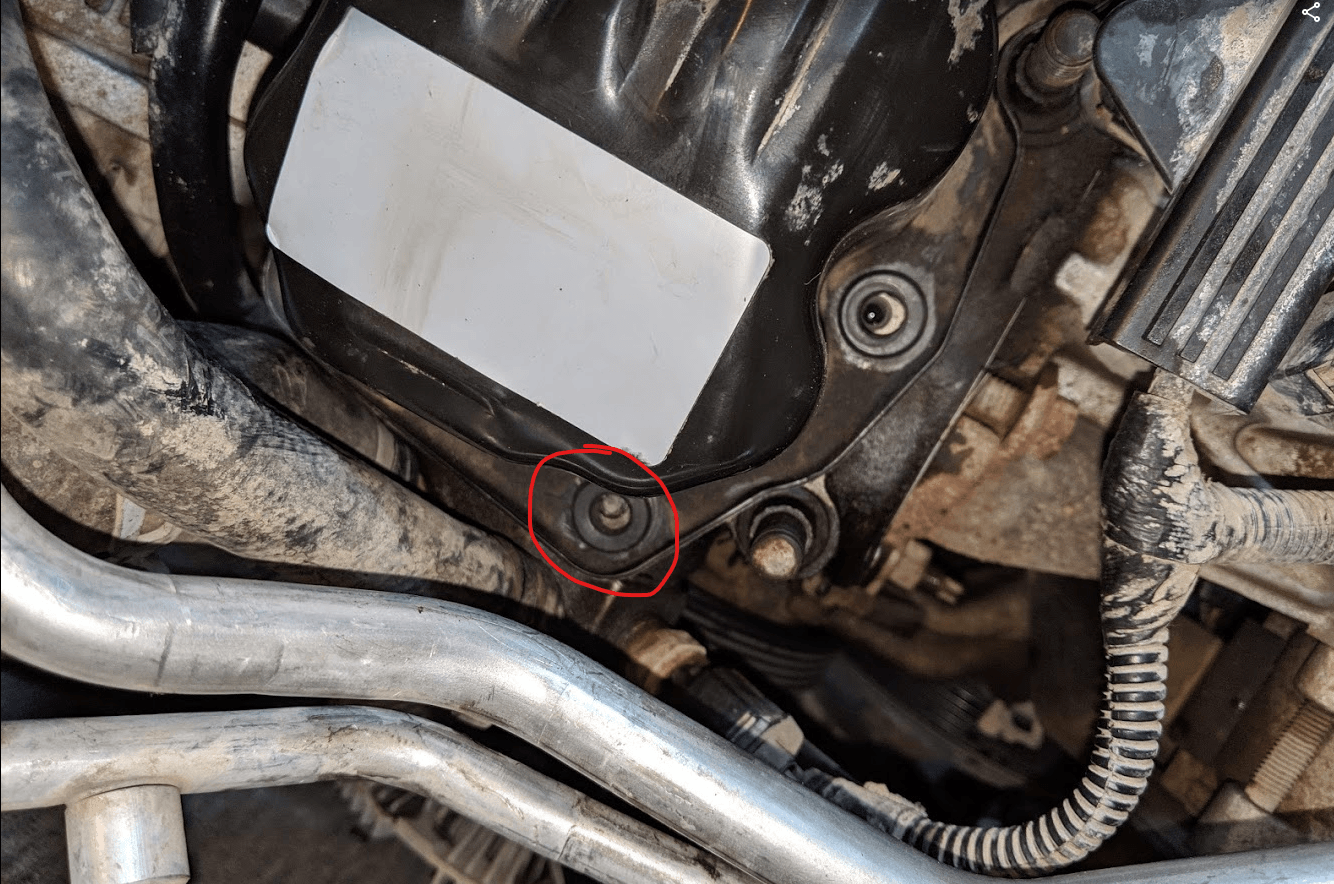

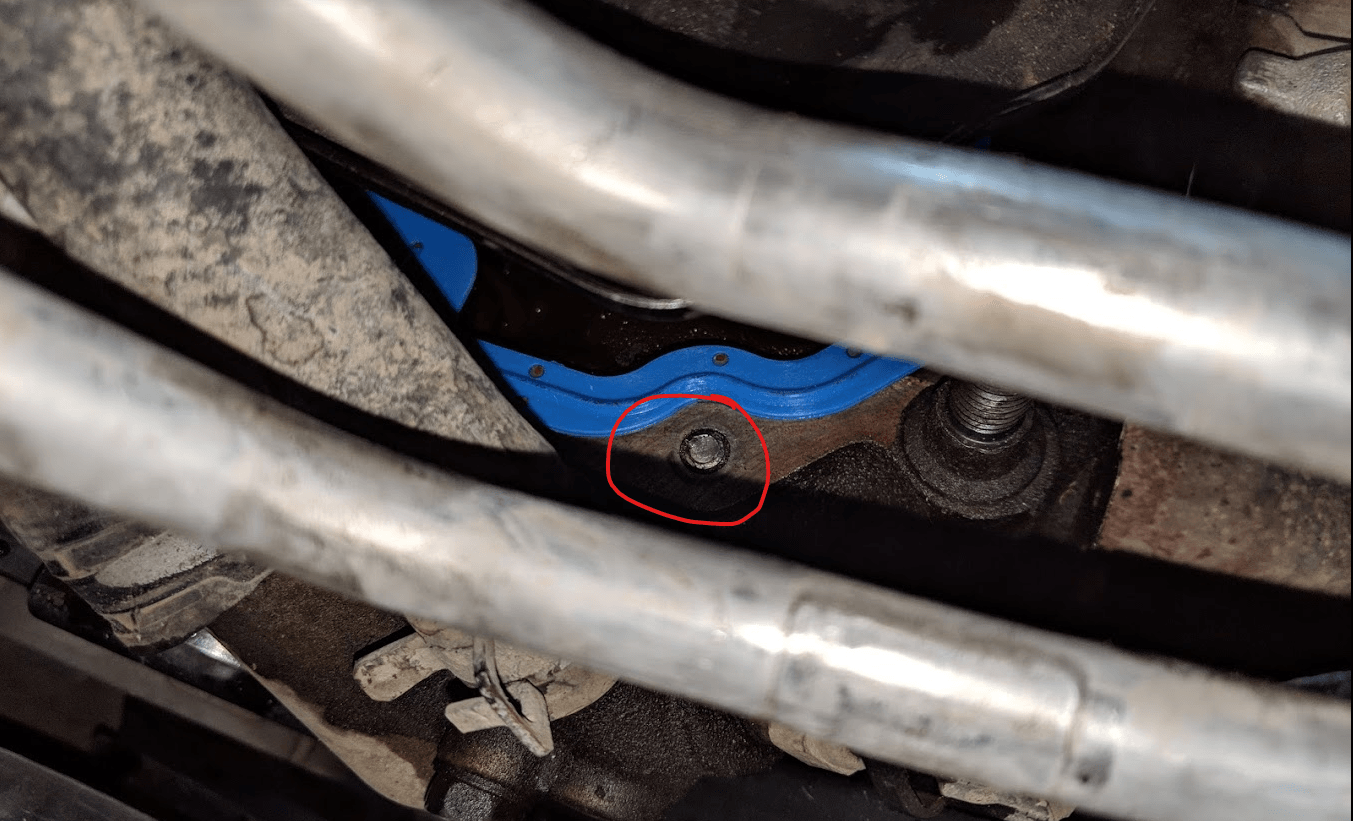

I was replacing my valve cover gasket today when I found out that it already had a broken bolt. The head was stripped off nearly flush with the surface. It's bolt in the front, closest to the radiator. This is likely one of the causes of the leak I've had. I've already tried left threaded drill bits, PB blaster and similar tools to remove broken bolts. I've managed to drill into it a bit, but have not been able to get it moving out.

I'm still new to Jeeps and am building up my capabilities in working on it:

I'm still new to Jeeps and am building up my capabilities in working on it:

- Is it an issue to drive with 1 bolt missing on the valve cover?

- I'm assuming it will just continue with the leak its had.

- How difficult is it to remove the refigerant lines for the A/C?

- They have been in the way while trying to get the broken bolt out and don't seem easy to remove.

- is this something a mechanic can remove without major costs?