I recently bought a Clover Leaf Roll for my LJ and quickly realized I didn't want to throw the thing in the cargo area and have it just roll around back there. I figured at some point, I'd be in a hurry and I'd open the rear door and the roll would fall out into a puddle or something; so I wanted to avoid that.

I wanted something that was all black to better blend in with the cargo carpeting and ultimately I wanted to use make use of the footman loops to secure the bag. I could have bought a bag, sure, but they were either too big or too small. There were no Goldilocks' sizes available. I did a quick sketch of what I was thinking about, ordered some 1000D Cordura and hardware, then tweaked that sketch as I waited for everything to arrive. Yesterday I got to work on this project.

First things first. If you have never worked with nylon, cutting it with scissors sucks because it just frays and frays. I bought a hot knife specifically for this project as the components are all nylon and the knife made working with it a breeze. Squeeze the trigger a few seconds here and there and cut away. The heat cauterizes the edges so there's no fraying. TOTALLY WORTH IT. (I have a jacket project I've been putting off because it is also nylon, so this wasn't a one-time use purchase.) It works its magic with Cordura, webbing, and 550 cord. I highly recommend one if you work with synthetics.

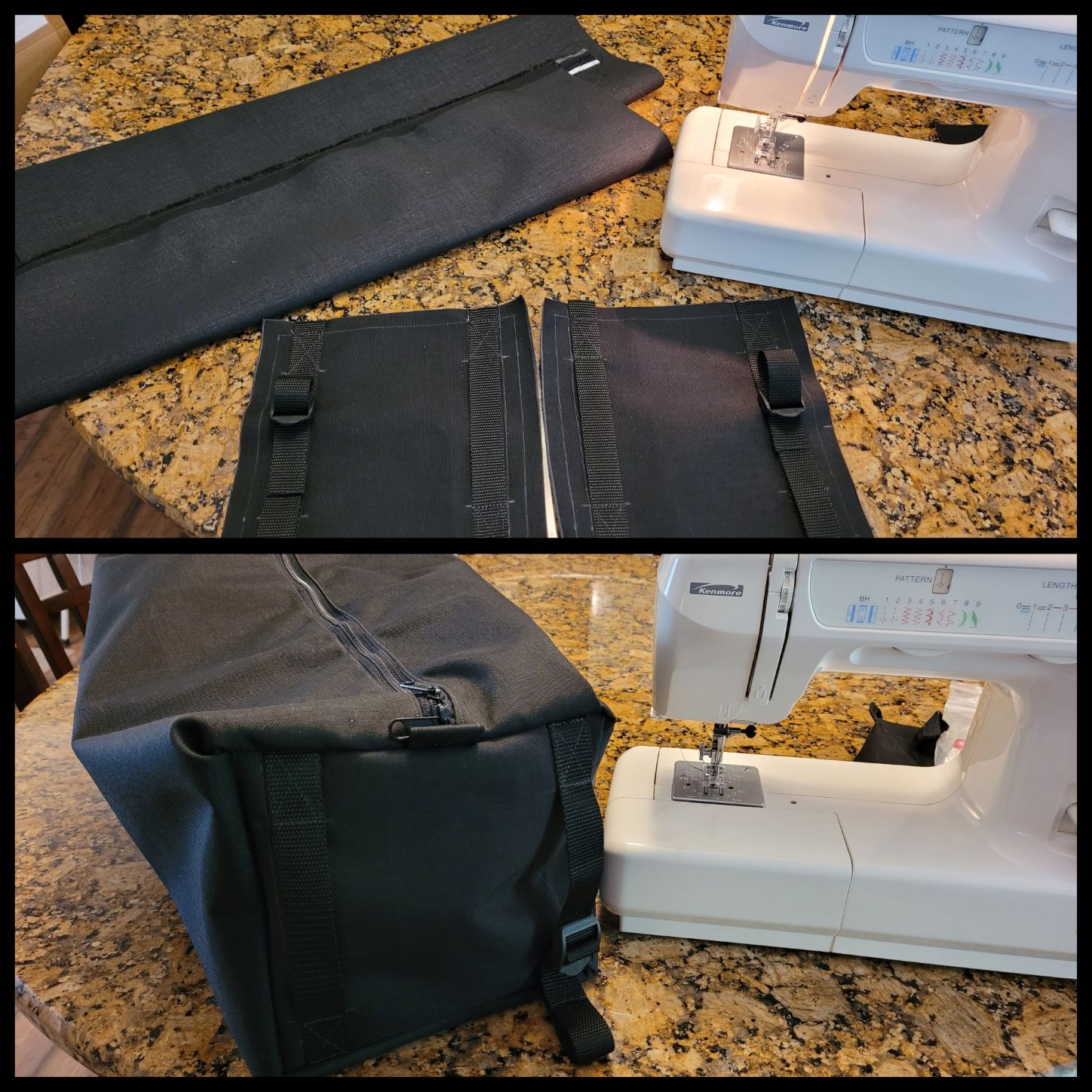

Here's the bag's components; two end pieces (9"x9") and one main bag body (25"x36.5"). The securing straps (1"x20" w/ sliding ladderlock buckle) were offset to the bag's 'rear' edge because of where the footman loops are and I wanted the bag as close to the seat as possible. I was in the cargo area with one of the bag's end pieces and long securing straps confirming that strap's placement when I realized I could add another strap (1"x9") to 'front' edge. It would make a pseudo-handle and a place to clip things if wanted later. The lower picture shows this layout/test fit. The piece of fabric on the glass is scrap I used to make the tabs (two 3"x3" squares) for the each of the zipper's ends.

Here's everything going together. I did an "X" stitch on the strap ends for durability, and the outer parts of those ended up in the bag seams, which I wanted. When I sewed the ends onto the main body, the long end of each securing strap was folded back on itself which captured part of this strap in the bag seam. My thought process was even if this seam rips out the bag would still be secured in the vehicle because the 'X' stitch is holding the strap to the bag. It closes up with a dual-zipper (27" cut to size after installation). My corners need a little work and I'm fighting the urge to take it apart and redo them.

Here is the finished bag in sunlight.

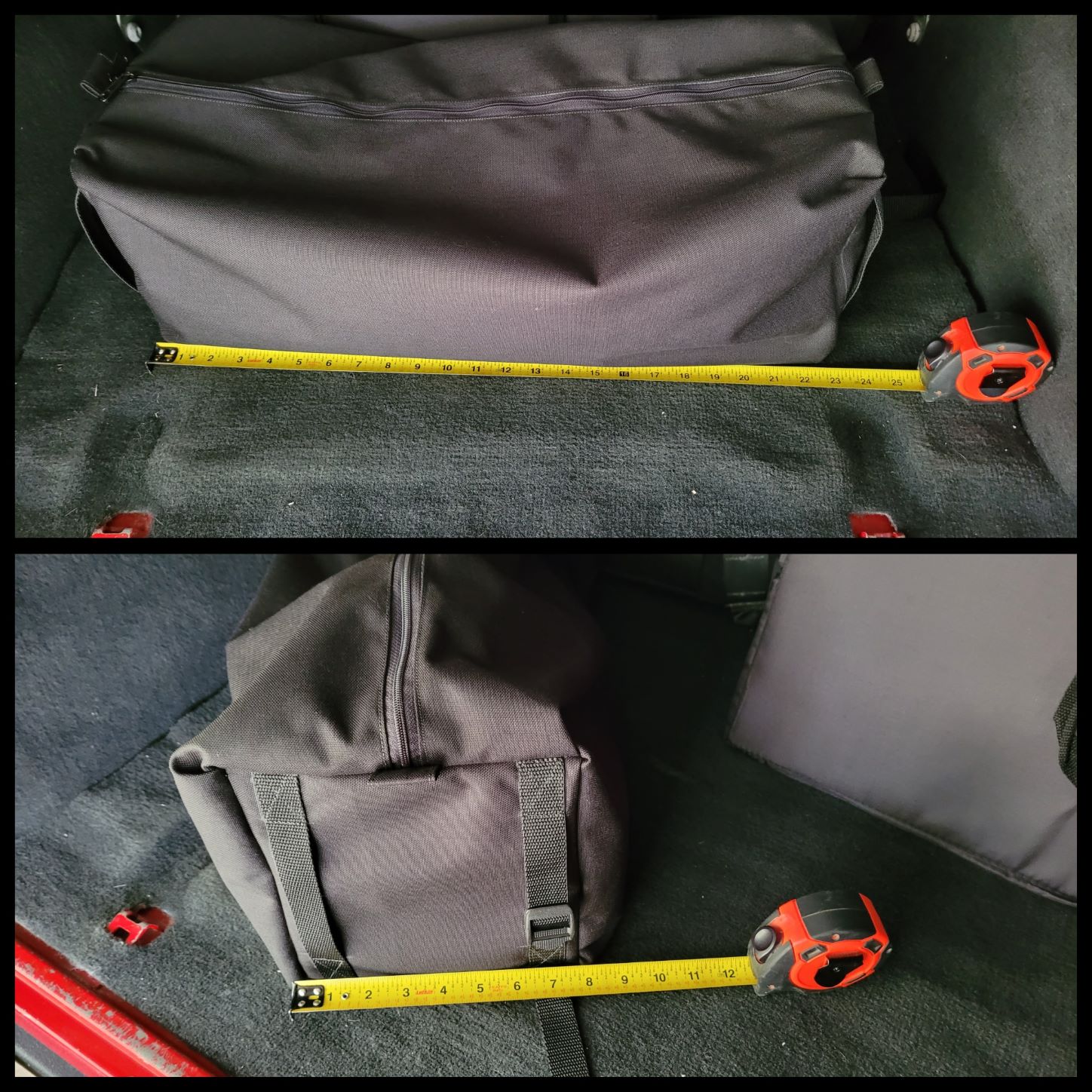

Before I secured it in the Jeep I took its measurements.

Here's the securing straps in action. Run the free end under the footman loops, back up to the sliding ladderlock buckles, and then tighten down. Why the sliding buckle? One, it was easier to sew that way. Two, it makes adjusting and fastening to the Jeep easier. I also thought one could use the bag elsewhere so having some adjustment capability baked in would be a good thing.

Finally, here it is in use. The Cover Patch Roll is inside the duffel. As and added bonus, I have a trunk organizer I stored under the rear seat in there as well. It's one of those fold-up rectangular things for when you go get groceries and don't want milk jugs rolling around during the ride home. Getting it out from under the seat was a pain, so I was happy to discover it fit in with the window roll. There's still some space, so some gloves or some cleaning rags might make their way into there. I sized the duffel to fit between the loops, so that open space on each side of the bag is intentional. I typically put my work bag up against the passenger side wheel well and didn't want to loose that capability. The storage duffel blends in nicely with the carpeting and having tinted windows makes it a little harder to see if you're just passing by.

A few frustrating points with my sewing machine (use a heavy-duty needle for sure), but ultimately everything worked out.

Thanks for looking!

BTW, if you try this, I recommend this video as its what I used as a reference/guide during assembly:

I wanted something that was all black to better blend in with the cargo carpeting and ultimately I wanted to use make use of the footman loops to secure the bag. I could have bought a bag, sure, but they were either too big or too small. There were no Goldilocks' sizes available. I did a quick sketch of what I was thinking about, ordered some 1000D Cordura and hardware, then tweaked that sketch as I waited for everything to arrive. Yesterday I got to work on this project.

First things first. If you have never worked with nylon, cutting it with scissors sucks because it just frays and frays. I bought a hot knife specifically for this project as the components are all nylon and the knife made working with it a breeze. Squeeze the trigger a few seconds here and there and cut away. The heat cauterizes the edges so there's no fraying. TOTALLY WORTH IT. (I have a jacket project I've been putting off because it is also nylon, so this wasn't a one-time use purchase.) It works its magic with Cordura, webbing, and 550 cord. I highly recommend one if you work with synthetics.

Here's the bag's components; two end pieces (9"x9") and one main bag body (25"x36.5"). The securing straps (1"x20" w/ sliding ladderlock buckle) were offset to the bag's 'rear' edge because of where the footman loops are and I wanted the bag as close to the seat as possible. I was in the cargo area with one of the bag's end pieces and long securing straps confirming that strap's placement when I realized I could add another strap (1"x9") to 'front' edge. It would make a pseudo-handle and a place to clip things if wanted later. The lower picture shows this layout/test fit. The piece of fabric on the glass is scrap I used to make the tabs (two 3"x3" squares) for the each of the zipper's ends.

Here's everything going together. I did an "X" stitch on the strap ends for durability, and the outer parts of those ended up in the bag seams, which I wanted. When I sewed the ends onto the main body, the long end of each securing strap was folded back on itself which captured part of this strap in the bag seam. My thought process was even if this seam rips out the bag would still be secured in the vehicle because the 'X' stitch is holding the strap to the bag. It closes up with a dual-zipper (27" cut to size after installation). My corners need a little work and I'm fighting the urge to take it apart and redo them.

Here is the finished bag in sunlight.

Before I secured it in the Jeep I took its measurements.

Here's the securing straps in action. Run the free end under the footman loops, back up to the sliding ladderlock buckles, and then tighten down. Why the sliding buckle? One, it was easier to sew that way. Two, it makes adjusting and fastening to the Jeep easier. I also thought one could use the bag elsewhere so having some adjustment capability baked in would be a good thing.

Finally, here it is in use. The Cover Patch Roll is inside the duffel. As and added bonus, I have a trunk organizer I stored under the rear seat in there as well. It's one of those fold-up rectangular things for when you go get groceries and don't want milk jugs rolling around during the ride home. Getting it out from under the seat was a pain, so I was happy to discover it fit in with the window roll. There's still some space, so some gloves or some cleaning rags might make their way into there. I sized the duffel to fit between the loops, so that open space on each side of the bag is intentional. I typically put my work bag up against the passenger side wheel well and didn't want to loose that capability. The storage duffel blends in nicely with the carpeting and having tinted windows makes it a little harder to see if you're just passing by.

A few frustrating points with my sewing machine (use a heavy-duty needle for sure), but ultimately everything worked out.

Thanks for looking!

BTW, if you try this, I recommend this video as its what I used as a reference/guide during assembly:

Last edited: