So about 2 weeks ago, I replaced the clutch and rear main seal in my 4 cylinder Jeep. It had a decent leak that I traced with UV dye to the rear of the oil pan and there wasn't any coming down from above, so with 179000 on the odometer and an unknown clutch age, it was time to do both. The clutch had some shuddering a take-off, so I thought maybe it had been done before by someone who had it resurfaced incorrectly. I thought I'd post a little of my experience, since I've benefitted enormously from reading the forum. Most of the YouTube guides are for the more common 6 cylinder, so I here's what I found:

These two videos were extremely helpful - one is for the 6 cylinder but it was pretty much the same to drop the AX-5 vs the AX-15. Pulled the transmission and the transfer case as one piece with a Harbor Freight transmission jack.

Only real issue I had with the removal was the gearshift lever, the FSM says to shift into 1st or 3rd for removing it, but I could not get the lock collar to rotate without it being in neutral. Came right off once I did that and reinstalled the same way.

The top two bolts on my AX-5 were the same hex head as the rest of the transmission to engine bolts, no E12 up there. Looking at the 97 parts list diagram, it calls out hex head bolts for the top two positions, so maybe the E12's are only on the 6 cylinder models?

Once piece rear main seal, replaced it with a Timken rear main seal. The original one had a felt ring, but this one was reinforced rubber. Hope it works!

I replaced the pivot in the bellhousing, as well as the clip that holds the clutch fork in place on it.

Used the Luk clutch kit, and a Timken throwout bearing as well. Also replaced the flywheel with a Luk one. I was never able to find replacement bolts for the flywheel, so I reused the original ones with blue Loc-tite. The bolts are tightened to I believe 50 ft/lbs and then 60 degrees extra. I looked high and low and couldn't find brand new ones. Not sure what to do in the future if they ever need replacing. They are a 7/16" x 24 bolt, which I couldn't even find a generic one anywhere. Plenty of 7/16" x 20 pitch, but the parts list identifies them as 24 pitch, and are no longer made. I measured the bolts when they were out and they were in fact 24 pitch. Hate to think that someday this engine could be condemned for the lack of 6 flywheel bolts that aren't made anymore, but hopefully that is a long way off!

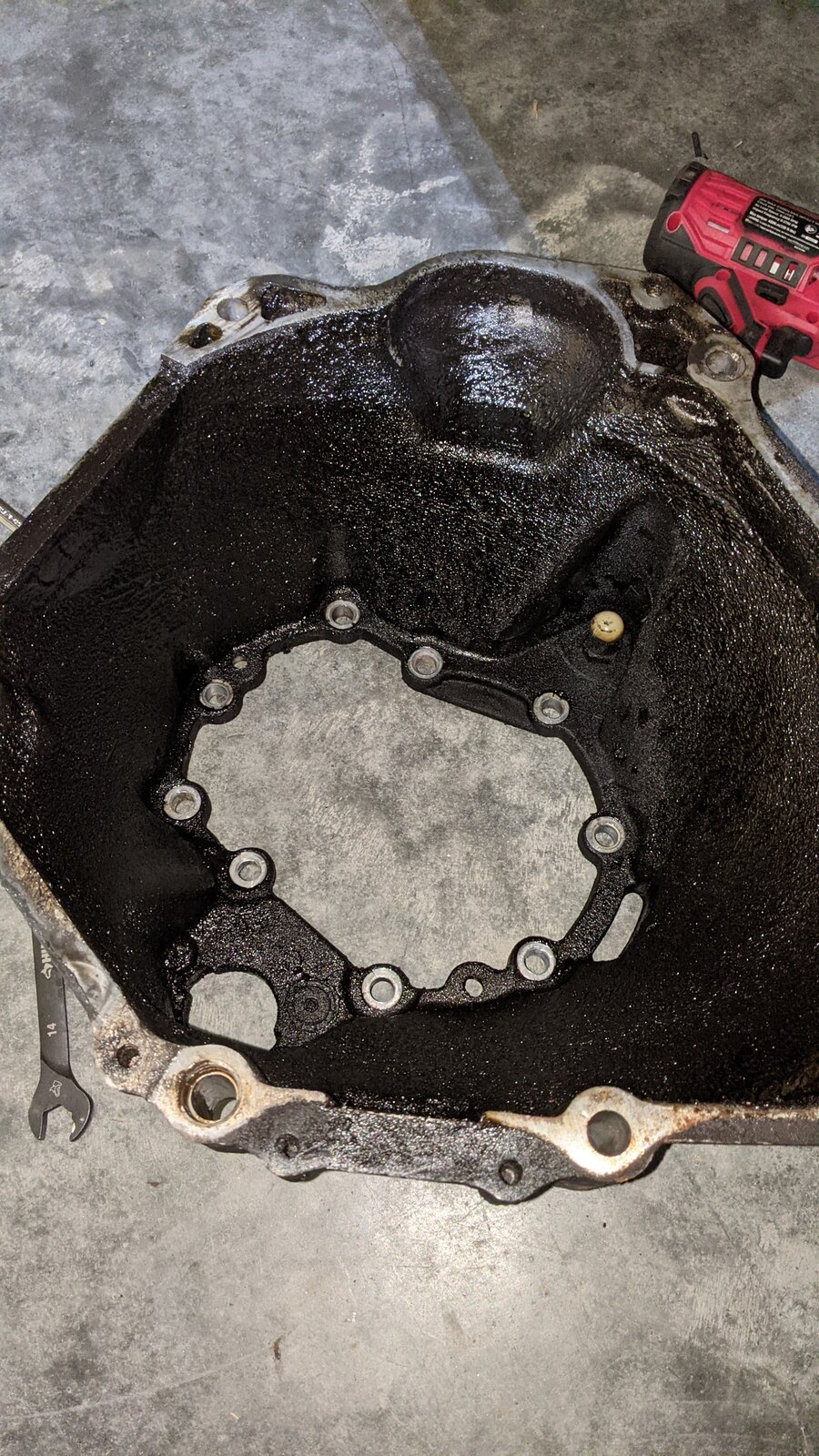

Total mess inside the bell housing of clutch dust and baked on oil, took about a couple of hours of cleaning and pressure washing to get all that gunk out.

Everything went back together fairly easily, no real issues there. And also, happy to report that there are no longer any oil leaks, and the clutch is totally smooth now. Overall, it was a decent long weekend's worth of work, but I'm pretty pleased with how it turned out. Happy to answer any questions about it since this combo of engine and trans isn't as common as the 6 cylinder. We basically use the Jeep as a family convertible (I know, for shame...) and don't go off road, so this little engine and trans does all right for our needs.

These two videos were extremely helpful - one is for the 6 cylinder but it was pretty much the same to drop the AX-5 vs the AX-15. Pulled the transmission and the transfer case as one piece with a Harbor Freight transmission jack.

Only real issue I had with the removal was the gearshift lever, the FSM says to shift into 1st or 3rd for removing it, but I could not get the lock collar to rotate without it being in neutral. Came right off once I did that and reinstalled the same way.

The top two bolts on my AX-5 were the same hex head as the rest of the transmission to engine bolts, no E12 up there. Looking at the 97 parts list diagram, it calls out hex head bolts for the top two positions, so maybe the E12's are only on the 6 cylinder models?

Once piece rear main seal, replaced it with a Timken rear main seal. The original one had a felt ring, but this one was reinforced rubber. Hope it works!

I replaced the pivot in the bellhousing, as well as the clip that holds the clutch fork in place on it.

Used the Luk clutch kit, and a Timken throwout bearing as well. Also replaced the flywheel with a Luk one. I was never able to find replacement bolts for the flywheel, so I reused the original ones with blue Loc-tite. The bolts are tightened to I believe 50 ft/lbs and then 60 degrees extra. I looked high and low and couldn't find brand new ones. Not sure what to do in the future if they ever need replacing. They are a 7/16" x 24 bolt, which I couldn't even find a generic one anywhere. Plenty of 7/16" x 20 pitch, but the parts list identifies them as 24 pitch, and are no longer made. I measured the bolts when they were out and they were in fact 24 pitch. Hate to think that someday this engine could be condemned for the lack of 6 flywheel bolts that aren't made anymore, but hopefully that is a long way off!

Total mess inside the bell housing of clutch dust and baked on oil, took about a couple of hours of cleaning and pressure washing to get all that gunk out.

Everything went back together fairly easily, no real issues there. And also, happy to report that there are no longer any oil leaks, and the clutch is totally smooth now. Overall, it was a decent long weekend's worth of work, but I'm pretty pleased with how it turned out. Happy to answer any questions about it since this combo of engine and trans isn't as common as the 6 cylinder. We basically use the Jeep as a family convertible (I know, for shame...) and don't go off road, so this little engine and trans does all right for our needs.