I had the hood open today, adding a secondary return spring to my throttle (it's a 2005 4.0L and only had the onboard/inline spring) as a short term experiment. I was poking around, looking at the vacuum lines just to understand where everything connects. I've never really paid attention to them, but I'm glad I did today.

While lightly tracing the line that runs from the speed control back towards the engine I got to where the main harness plugs into the block and the rubber elbow was loose. I thought that's not good and I when I touched the elbow it was soft. Like, it would crumble to dust if I tried messing with it more than I did.

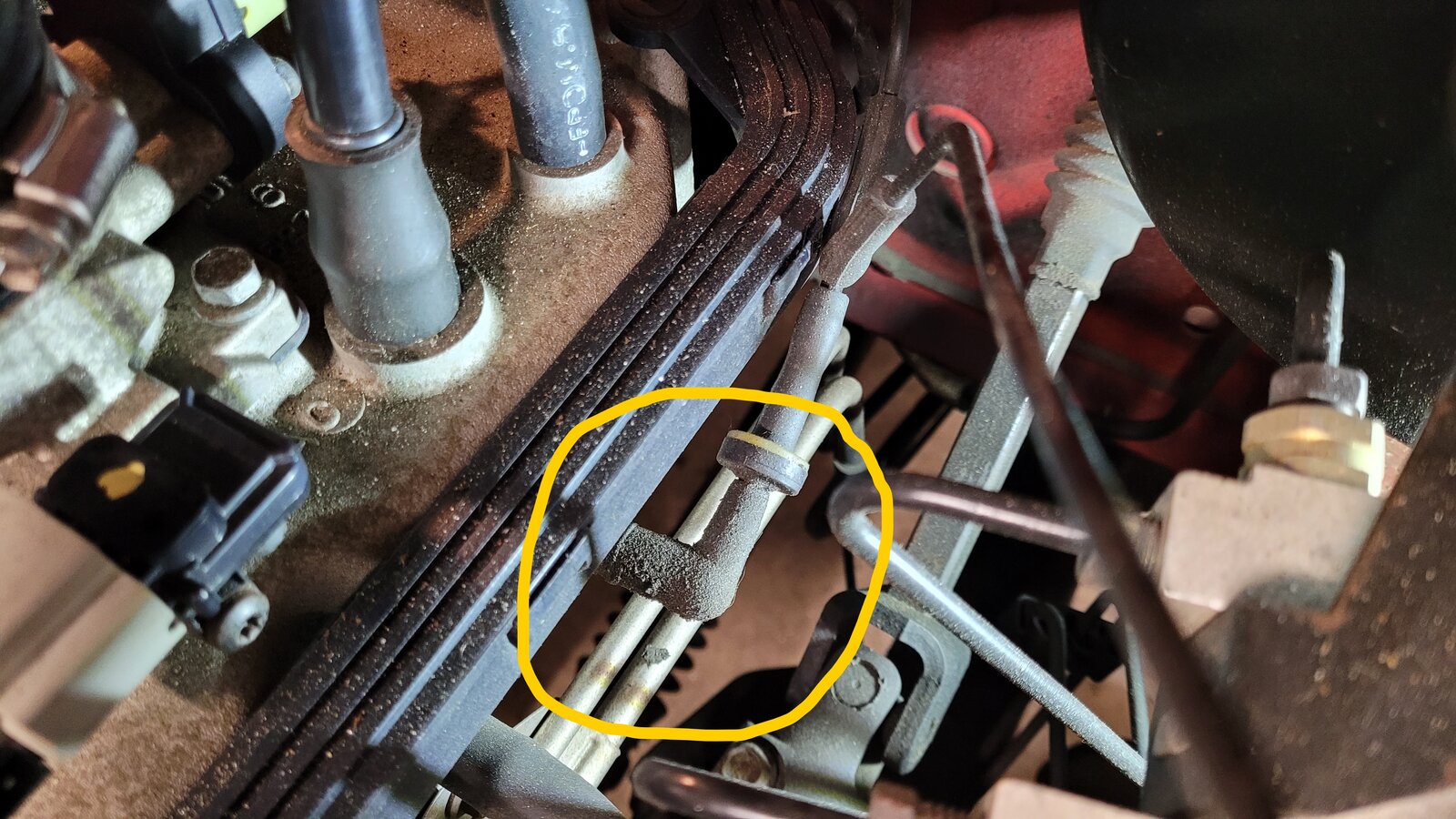

I circled the part I'm talking about and you can see the flake of rubber that fell off below the elbow.

So I came right in, fired up this forum and searched for help on what the heck I needed. A Mopar 55037637AB vacuum harness is now on order.

I'm assuming this will be a detach and replace procedure? Meaning, unplug old and plug in new; just taking time to not crack, break, or tear any of the other connections in the process? Any other tips from those who have done this swap? Thanks in advance.

While lightly tracing the line that runs from the speed control back towards the engine I got to where the main harness plugs into the block and the rubber elbow was loose. I thought that's not good and I when I touched the elbow it was soft. Like, it would crumble to dust if I tried messing with it more than I did.

I circled the part I'm talking about and you can see the flake of rubber that fell off below the elbow.

So I came right in, fired up this forum and searched for help on what the heck I needed. A Mopar 55037637AB vacuum harness is now on order.

I'm assuming this will be a detach and replace procedure? Meaning, unplug old and plug in new; just taking time to not crack, break, or tear any of the other connections in the process? Any other tips from those who have done this swap? Thanks in advance.