You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Diff pro needed: Ford 8.8 carrier too tight with new locker?

- Thread starter TimboSlice

- Start date

That is why you need a shim kit. That way you can have different sized thick shims.

I have them. Thats how I got to my .002 backlash. I just used the cast 1 piece shim on the left and the shim kit on the right. Ended up with the .002 backlash before I called it a night. Looks like I will need to measure 1 piece shim on left and make a shim pack .006 less than original one piece shim. Then configure a shim set to add .006 to current shim set on right.

You're on the right track, just keep moving things around until you have the correct bl and preload.

If your backlash is .002, you need to subtract shim from the left and add shim to the right. If you are using the solid cast shims you either need to find others of the correct thickness or use a different style of shim that sandwiches thinner shims between two thicker shims.

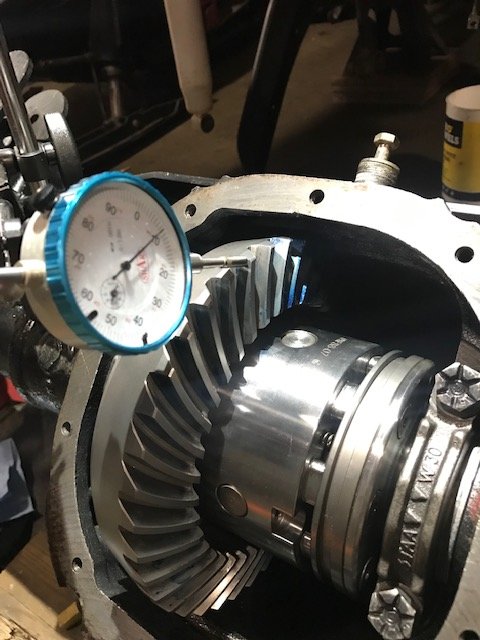

Just wanted to point out this great piece of advise that could come natural to some but not most. Sandwich the smallest shims between the larger ones. This tip will help anyone who is new at this. Its easy to over think the obvious when you are in the midst of learning. It will also save you a shim or two. Using good instruments for measuring is important also. I borrowed a cheap dial indicator from my cousin. So if this is off due to a crummy tool, i'm going to have his head. I have a very good caliper i am using to measure my shims and depth when need be. (mitutuyo) And will have a mic in hand tomorrow.

Last edited:

So a little update as I continued this tonight. I have my ring gear set at .010 backlash. Spec is .008-.012. I then torqued my bearing caps and had the same backlash when double checking. I marked the ring gear with paint and spun the gears. It seems dead on. I would like to share a few photos to get opinions on if I get this pattern correct.

Not a fan of the blue stuff, too hard to see patterns. But, looks pretty good.

Yeah I'd run it! I too like the yellow better, but with the exception of the first picture it looks pretty good. (the first picture is hard to make out, not that I see anything wrong there)