Export Taillights (this does require some rewiring to vehicle harness)

I'd like start out by saying certain aspects of this build were gained from an existing thread about the export style tail lights. Thank you to all who have contributed.

https://wranglertjforum.com/threads...us-tjs-without-having-to-run-new-wires.18771/

I wanted to do a comprehensive write up of my build, but there is certainly information in the other thread that will be omitted from the how-to. There will be a list of materials with links at the end of the post.

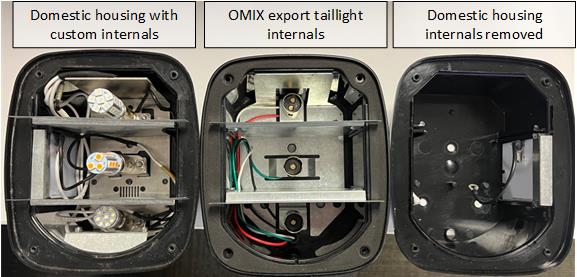

I ordered a set of used factory style taillights from Ebay. It had the 4 pin square style connector that my 2006 TJ has on the wiring harness. From what I understand different years had a flat style 4 pin connector. I chose to get a set of domestic taillights to modify because the house contains the required side reflector and side marker. Also, the driver side has the clear lens in the bottom of the housing for the factory license plate illumination.

The domestic style grounding plate inside the housing wouldn’t work for the export lenses. Aside from the obvious side & license plate lenses being different, there are minor interior differences between the two housings. I have friends at work that have access to the fabrication shop, so I figured I could measure both the export tail light and the domestic tail light and develop a grounding plate that could fit inside the domestic housing and fit the requisite 3 bulb sockets (1 – 1157 for the parking/brake bulb, 1 – 1156 for the turn indicator bulb, and 1 – 1156 for the reverse bulb).

Next, I needed to remove the grounding plate. I heated the tips of some needle nose pliers and began melting the plastic “rivets” hold the grounding plate against the housing. After melting/pinch the rivets, I cut the tops off with a razor blade. Once the three “rivets” were sliced off I was able to wiggle the grounding plate from the housing, although the wires were still connected.

I de-pinned the connector and was able to pull the wires through the housing.

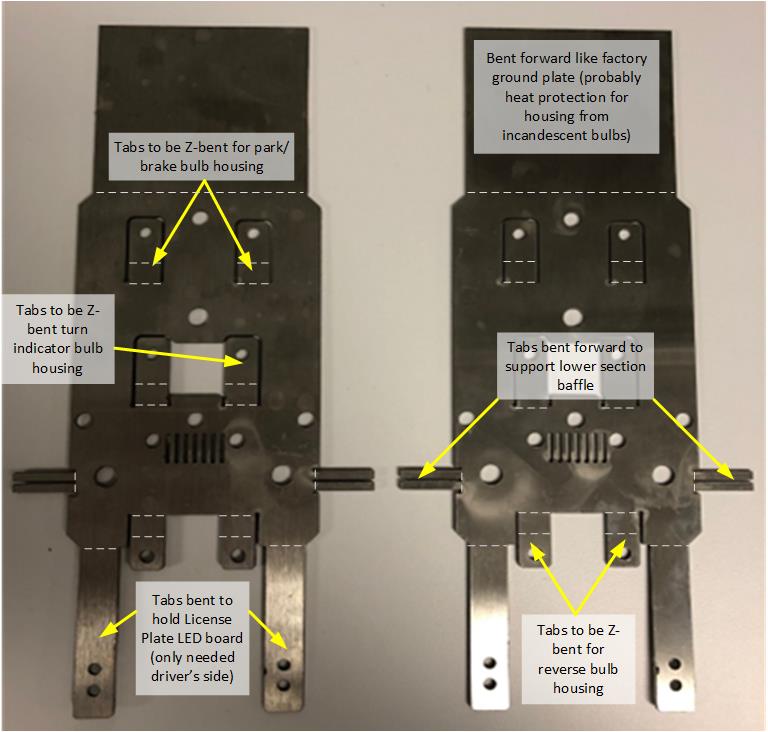

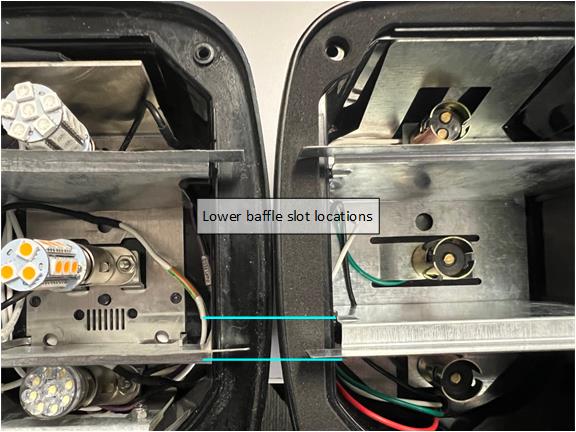

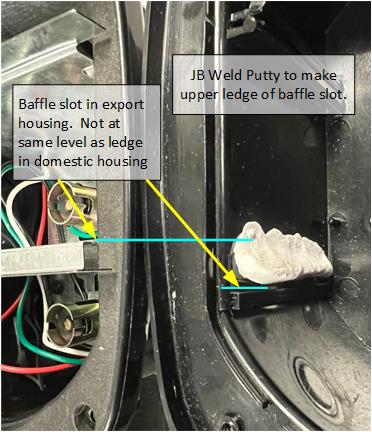

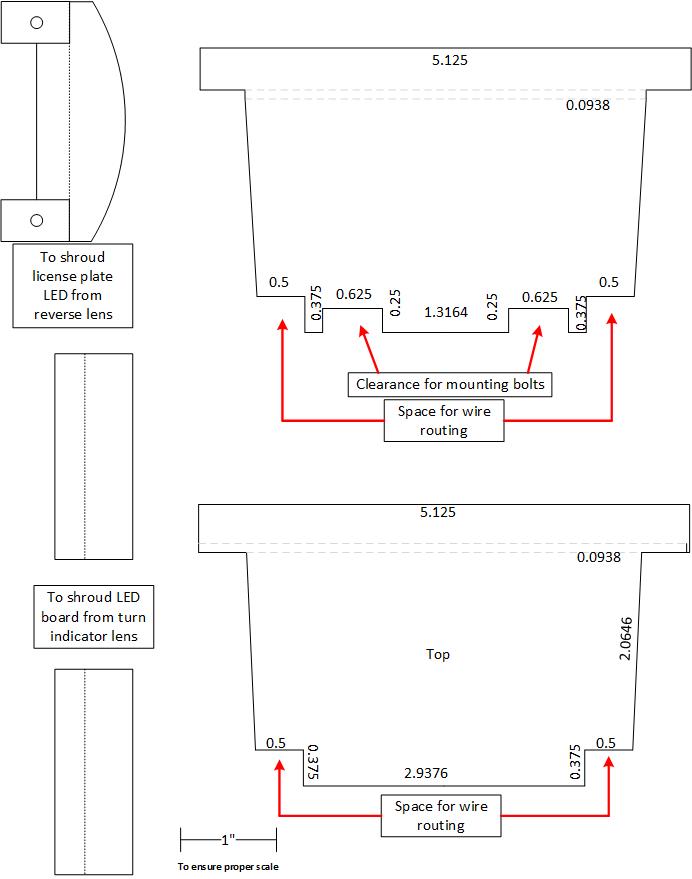

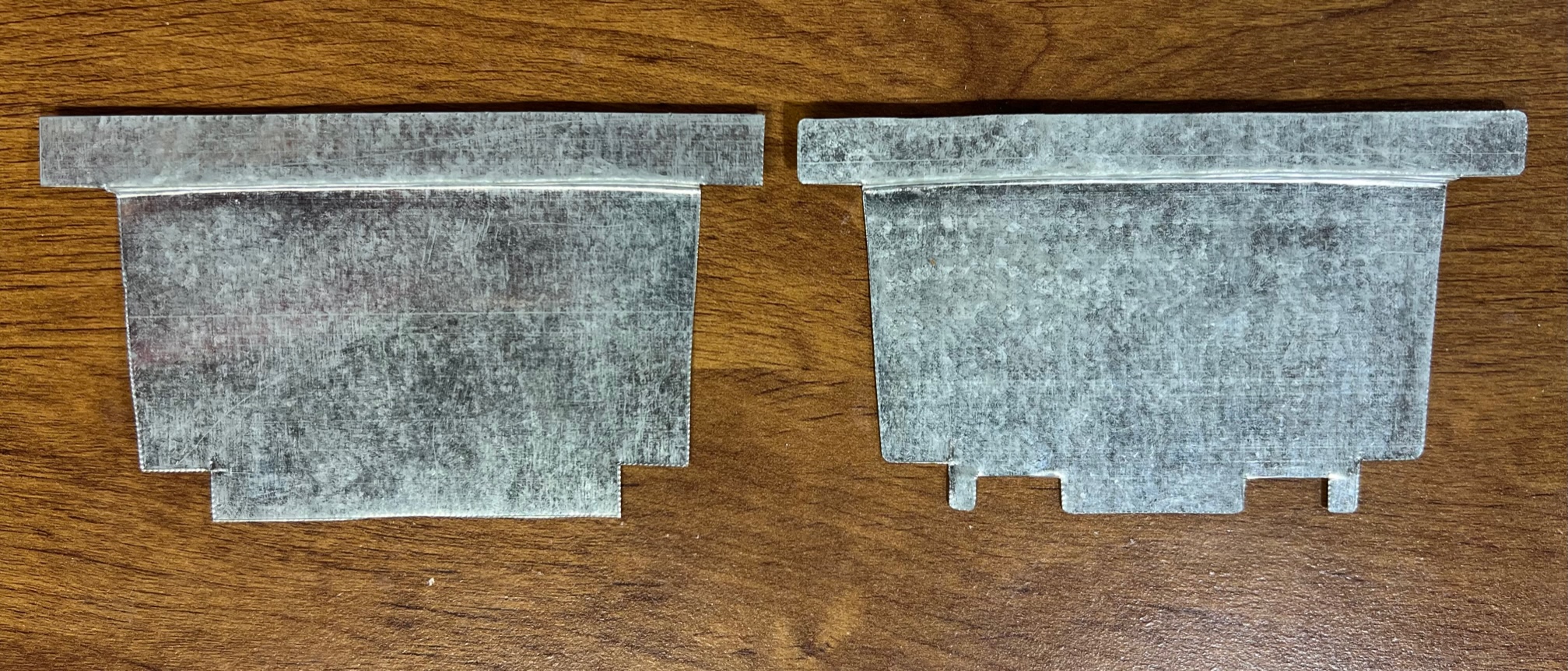

The slots in the domestic housing for the section baffles weren’t exactly the same as the export housing, so I also started figuring baffles that would work with the slots in the domestic housing. The final design file for the grounding plate is shown. I have it as both a Visio file (which is scalable) and DXF file which is what was used for the waterjet. I realized I didn’t need to completely block out the backup lamp from the license plate lens, as it will just illuminate the plate more while reversing.

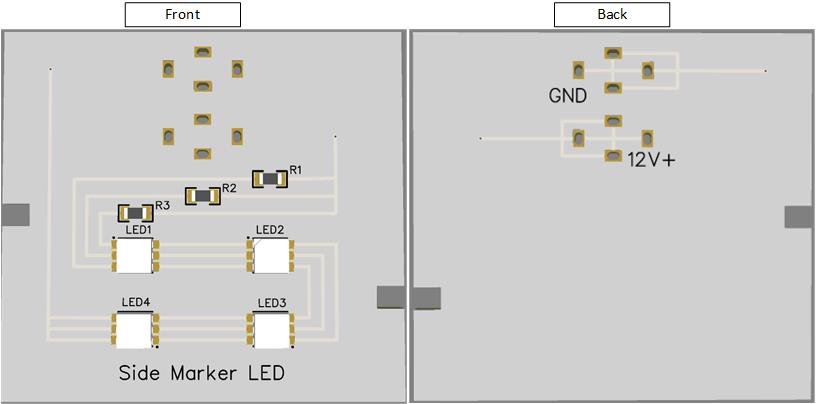

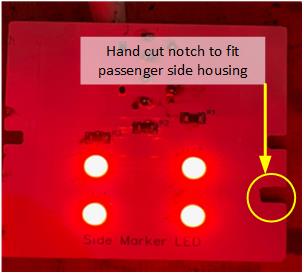

The PCBs were also iterative, but here’s what I ended up with for the side markers. There will be surface mount connectors placed in the holes at the top of the board.

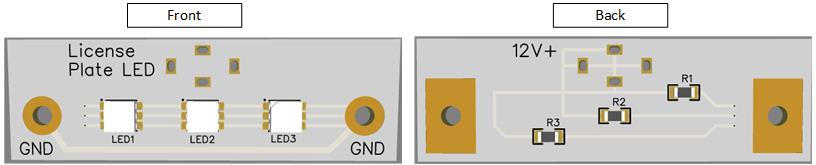

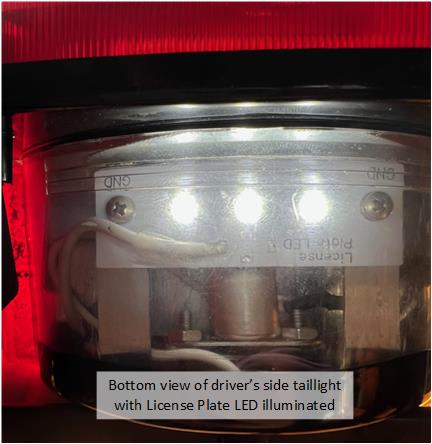

Here’s what I ended up with for the license plate light. This only needs a power wire that’s daisy chained to the side marker and parking lamp. This will screw to two tabs on the grounding plate and will just be grounded directly.

I will try to attach the gerber files for the circuit boards that I used to order them. Minimum order quantity from JLCPCB was 5 PCBs each, and was about $8 total.

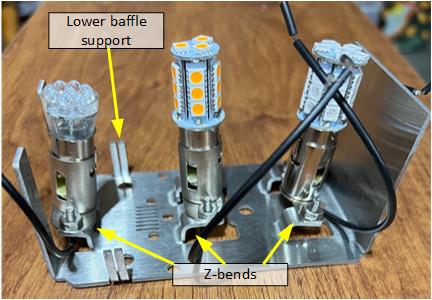

Grounding plate after being bent, with the bulb sockets attached.

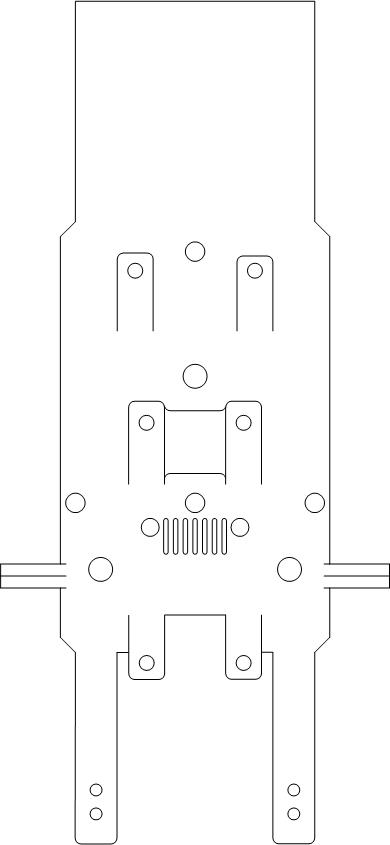

I wanted to post this picture as an SVG file which will be to scale. This jpeg SHOULD be to scale, but there is a 1" reference line on there to ensure correct scaling if printed.

I designed the Side Marker circuit board having only disassemble the driver's side taillight. The notch for the passenger side was NOT the same location, so I hand cut a notch into the board. The graphics above (in the design section) have been updated to move the notch for the passenger's side to the correct location.

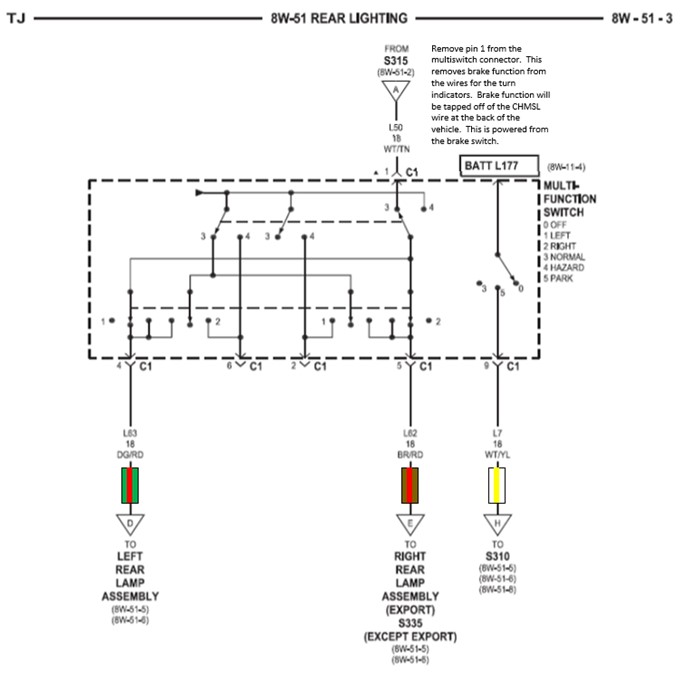

In order to remove the brake function from the turn indicator wires headed to the back of the vehicle, pin 1 will be removed from multifunction switch harness C1. The easiest thing to do would be to cut the wire, but I'm personally not a fan of cutting wires on a factory harness whenever possible.

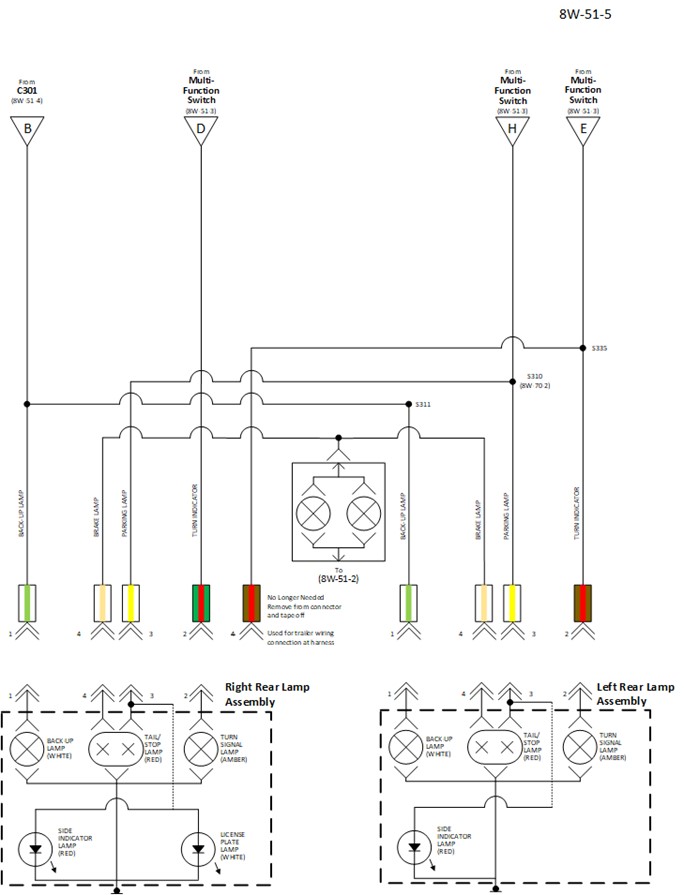

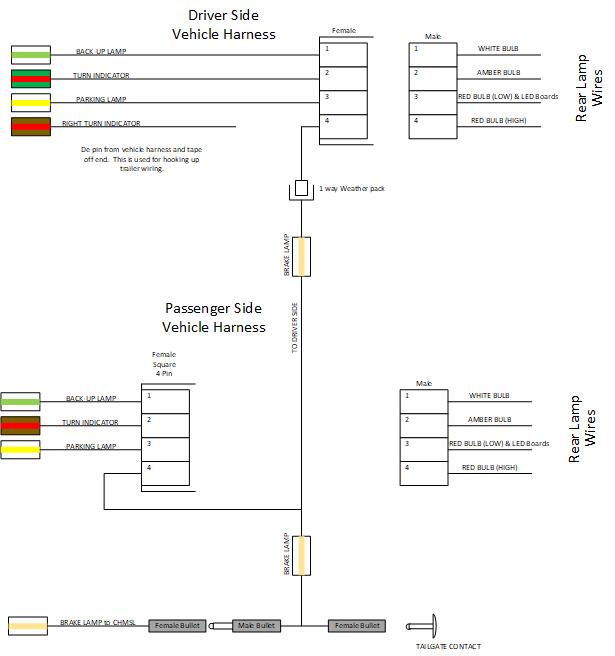

This is how I tapped into the CHMSL power that comes directly from the brake switch. I used a 1-way molded 12” connector that I turned into a plug-in T-splice. The female end will plug onto the tailgate contact after the tan/white wire (power to CHMSL) is removed. The male end will plug into the female connection on the tan/white wire. This provides a plugin splice without having to cut the factory wiring harness. Spliced into the 1-way molded connector will be 1 wire for the passenger side tail light brake light function, and another to run under the vehicle to the driver’s side to provide power to the driver’s side tail light brake light function. I put a 1-pin weather pack connector inline on this wire about 12” from the vehicle harness connector for the driver’s tail light so it wasn’t 1 long hard wired connection to ease wire routing up underneath the bumper near the gas tank.

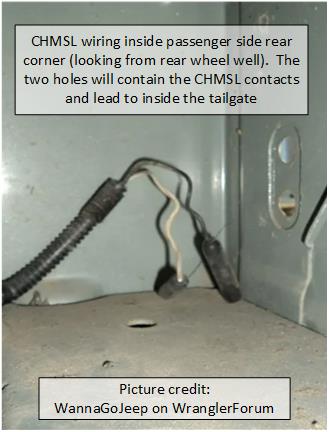

To add the T-splice on the CHMSL wire, I needed to remove the passenger side rear tire, and wheel well liner. The CHMSL wires are located by the gas tank evap cylinder. The taillight wires were also stuck on the evap system, so this allowed me to “free” them, so there was adequate slack to disconnect the connector of the original taillight, and plug in the new export style taillight. I learned this via WannaGoJeep’s post on WranglerForum.

The brown/red wire in the driver side harness connector is for T-splice quick connect trailer wiring. A previous owner ran a flat 4 trailer harness using 3M quick splices in by the hard top connector, so I didn’t need this quick connect functionality. Note: If you tow and have a trailer harness connected on the driver side tail light connector, this option will probably not work for you.

As I hopefully complete my install of this project this spring, I'll add more pictures. I've been sitting on this write up for a while and figured it should be posted.

I'd like start out by saying certain aspects of this build were gained from an existing thread about the export style tail lights. Thank you to all who have contributed.

https://wranglertjforum.com/threads...us-tjs-without-having-to-run-new-wires.18771/

I wanted to do a comprehensive write up of my build, but there is certainly information in the other thread that will be omitted from the how-to. There will be a list of materials with links at the end of the post.

I ordered a set of used factory style taillights from Ebay. It had the 4 pin square style connector that my 2006 TJ has on the wiring harness. From what I understand different years had a flat style 4 pin connector. I chose to get a set of domestic taillights to modify because the house contains the required side reflector and side marker. Also, the driver side has the clear lens in the bottom of the housing for the factory license plate illumination.

The domestic style grounding plate inside the housing wouldn’t work for the export lenses. Aside from the obvious side & license plate lenses being different, there are minor interior differences between the two housings. I have friends at work that have access to the fabrication shop, so I figured I could measure both the export tail light and the domestic tail light and develop a grounding plate that could fit inside the domestic housing and fit the requisite 3 bulb sockets (1 – 1157 for the parking/brake bulb, 1 – 1156 for the turn indicator bulb, and 1 – 1156 for the reverse bulb).

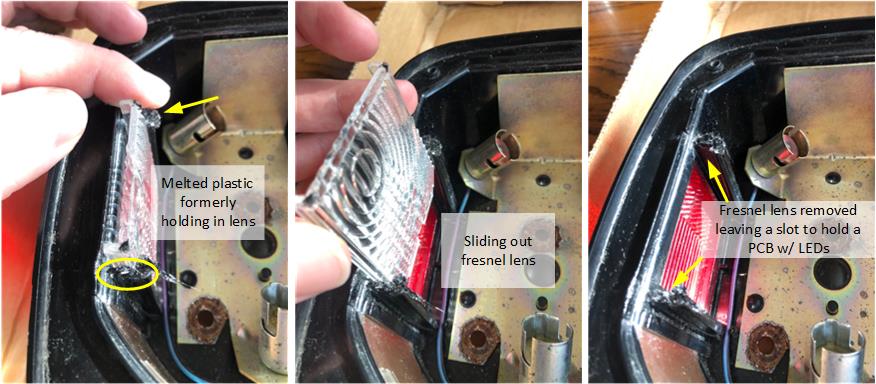

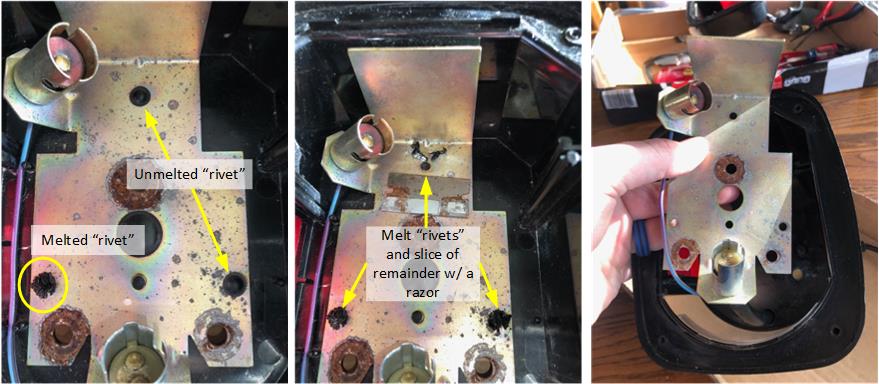

Disassembly of Domestic Taillight Housings

I started by removing the fresnel lens on the inside of the domestic housing for the side marker illumination. This slot would make a great place for a printed circuit board (PCB) with some LEDs for the side marker, and the solid nature of the PCB would block out the blinking light of the turn indicator from the side marker. I used a soldering iron to carefully heat the plastic that was holding the Fresnel lens and would pry it away from the lens’ plastic with a screwdriver. Eventually enough was out of the way to remove the lens.Next, I needed to remove the grounding plate. I heated the tips of some needle nose pliers and began melting the plastic “rivets” hold the grounding plate against the housing. After melting/pinch the rivets, I cut the tops off with a razor blade. Once the three “rivets” were sliced off I was able to wiggle the grounding plate from the housing, although the wires were still connected.

I de-pinned the connector and was able to pull the wires through the housing.

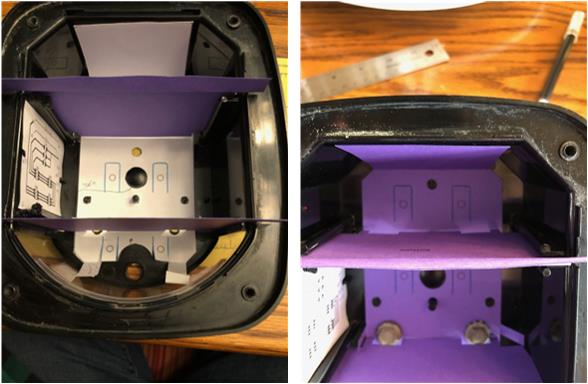

Grounding Plate Design

The design of the grounding plate was an iterative process of taking some measurements, print out a scale copy, cut it out, see where things fit/didn’t fit, etc. Here’s some in process shots of various iterations. Also during this process I found a website that had a free PCB designer and started to design PCBs that could hold LEDs for the side marker and the license plate light.The slots in the domestic housing for the section baffles weren’t exactly the same as the export housing, so I also started figuring baffles that would work with the slots in the domestic housing. The final design file for the grounding plate is shown. I have it as both a Visio file (which is scalable) and DXF file which is what was used for the waterjet. I realized I didn’t need to completely block out the backup lamp from the license plate lens, as it will just illuminate the plate more while reversing.

Printed Circuit Board Design - Side Markers and License Plate LEDs

Note: I have zero previous experience designing circuit boards. I have a reasonable understanding of simple electrical circuits (primarily LED circuits), but I stumbled through this using EasyEDA via JLCPCB's website.The PCBs were also iterative, but here’s what I ended up with for the side markers. There will be surface mount connectors placed in the holes at the top of the board.

Here’s what I ended up with for the license plate light. This only needs a power wire that’s daisy chained to the side marker and parking lamp. This will screw to two tabs on the grounding plate and will just be grounded directly.

I will try to attach the gerber files for the circuit boards that I used to order them. Minimum order quantity from JLCPCB was 5 PCBs each, and was about $8 total.

Grounding Plates

I had the grounding plate cut out of stainless on the water jet at my work’s machine shop. The Z bends for the light sockets were done by hand with a vise, metal block, and a hammer. The sockets are grounded to plate when bolted/screwed in place, and the ground plate is grounded to the body/frame with the mounting bolts used to attach the taillight housing to the Jeep body.Grounding plate after being bent, with the bulb sockets attached.

Baffles

Interior baffles were hand bent using thin gauge metal flashing. These were not identical to those found in the OMIX export light. The interiors of the housings were slightly different, and the domestic housing had less baffle support channels, since they only require one interior baffle. I printed the templates out and I think I glued them to the flashing with a glue stick and then used aviation snips to cut the pieces out. I used sheet metal vise grips mostly to make these z-bends (dotted lines) on the baffles.I wanted to post this picture as an SVG file which will be to scale. This jpeg SHOULD be to scale, but there is a 1" reference line on there to ensure correct scaling if printed.

Taillight Assembly

LED Circuits Boards

I did not get pictures while I was soldering the circuit boards, but I was figuring that out as I went. I needed to buy a reflow station and solder paste to get the SMD components soldered onto the boards. I expect that there are different forums and/or Youtube resources to help this this.I designed the Side Marker circuit board having only disassemble the driver's side taillight. The notch for the passenger side was NOT the same location, so I hand cut a notch into the board. The graphics above (in the design section) have been updated to move the notch for the passenger's side to the correct location.

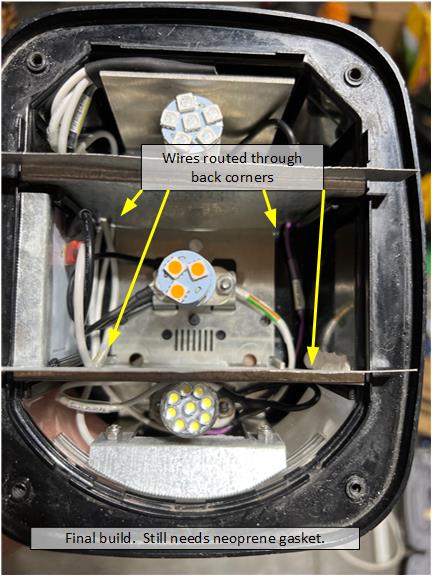

Assembly

Wiring is routed in the back corners of the housings like the factory wiring was. The cutouts in the baffles allow for upper wires to get to the bottom of the housing through which the pigtail exits.Vehicle Wiring Changes

Note: The following steps have not been completed as of 21-Mar-2024. I'm hoping for some warmer weather soon to be able to complete.In order to remove the brake function from the turn indicator wires headed to the back of the vehicle, pin 1 will be removed from multifunction switch harness C1. The easiest thing to do would be to cut the wire, but I'm personally not a fan of cutting wires on a factory harness whenever possible.

This is how I tapped into the CHMSL power that comes directly from the brake switch. I used a 1-way molded 12” connector that I turned into a plug-in T-splice. The female end will plug onto the tailgate contact after the tan/white wire (power to CHMSL) is removed. The male end will plug into the female connection on the tan/white wire. This provides a plugin splice without having to cut the factory wiring harness. Spliced into the 1-way molded connector will be 1 wire for the passenger side tail light brake light function, and another to run under the vehicle to the driver’s side to provide power to the driver’s side tail light brake light function. I put a 1-pin weather pack connector inline on this wire about 12” from the vehicle harness connector for the driver’s tail light so it wasn’t 1 long hard wired connection to ease wire routing up underneath the bumper near the gas tank.

To add the T-splice on the CHMSL wire, I needed to remove the passenger side rear tire, and wheel well liner. The CHMSL wires are located by the gas tank evap cylinder. The taillight wires were also stuck on the evap system, so this allowed me to “free” them, so there was adequate slack to disconnect the connector of the original taillight, and plug in the new export style taillight. I learned this via WannaGoJeep’s post on WranglerForum.

The brown/red wire in the driver side harness connector is for T-splice quick connect trailer wiring. A previous owner ran a flat 4 trailer harness using 3M quick splices in by the hard top connector, so I didn’t need this quick connect functionality. Note: If you tow and have a trailer harness connected on the driver side tail light connector, this option will probably not work for you.

As I hopefully complete my install of this project this spring, I'll add more pictures. I've been sitting on this write up for a while and figured it should be posted.

Bill of Materials

Item | Qty | Source | Part # / SKU | Comment |

| Reverse Bulbs | 2 | Super Bright LEDs | 67-W15-2PK | Link is for a 2 pack |

| Park/Brake Bulbs | 2 | Super Bright LEDs | 1157-R27-T-2PK | Link is for a 2 pack |

| Turn Indicator Bulbs | 2 | Super Bright LEDs | 1156-A18-T-2PK | Link is for a 2 pack |

| 1156 Sockets | 4 | Super Bright LEDs | BA15S-SW | Reverse & Turn sockets |

| 1157 Sockets | 2 | Super Bright LEDs | BA15D-SW | Park/Brake sockets |

| SMD LEDs (red) | 8 | Super Bright LEDs | 5050-R1200 | LEDs for side marker circuit board |

| SMD LEDs (white) | 3 | Super Bright LEDs | 5050-WW6000 (link) 5050-PW6000 (natural white I used) | The link is for warm white, as it does not look like they have the natural white color I ordered. This would still work fine. Only needed for driver side |

| 1206 SMD resistors (560W) | 9 | Digikey | 541-10664-1-ND | Appropriate surface mount resistors for the LEDs I used |

| SMD spade connectors (30°) | 4 | Digikey | 36-4908-ND | Spade connectors on side marker circuit boards for ground and power connections |

| Delphi GT280 Male Connector | 2 | 15304731-L | Male pins for taillight pigtail | |

| Delphi GT280 Female Connect | 2 | 15304719-L | Female pins for vehicle harness | |

| Delphi GT280 Cable Seal | 4 | 15366066 | Cable seals for above pins | |

| 1-way Sealed Weather Pack | 1 | WP01-20-18 | Disconnect point on brake wire running from passenger side to driver side | |

| 1-way Molded bullet connector | 1 | Del City | 74115 | It appears 84115 is the replacement part for 74115. Used to make a plug-in splice for CHMSL power to brake lights |

| 1/8" neoprene w/ adhesive | 1 | Amazon | | Gasket material |

| Marine Grade Heat Shrink | 1 | Amazon | | Heat shrink used to seal wires/pigtail coming out of tail light housing |

| Flashing for baffles | 4 | Lowes | A3X4X7 | Used for making the internal baffles. |

| JB Weld Plastic Epoxy | 1 | Anywhere that sells it | 8237 | Used to make the upper “lip” for lower baffles on the non-side marker wall of tail light housing |

| Export Tail Light Lenses | 2 | Quadratec | 55212-0051 83501003 | |

| Unlinked items | | | | |

| Assorted stainless machine screws | | | | |

| Assorted stainless nuts | | | | |

| Assorted heat shrink | | | | |

| Assorted wire and basic connectors | | | | |

| Used domestic tail lights | | U-Pull it / Ebay | |

Last edited: