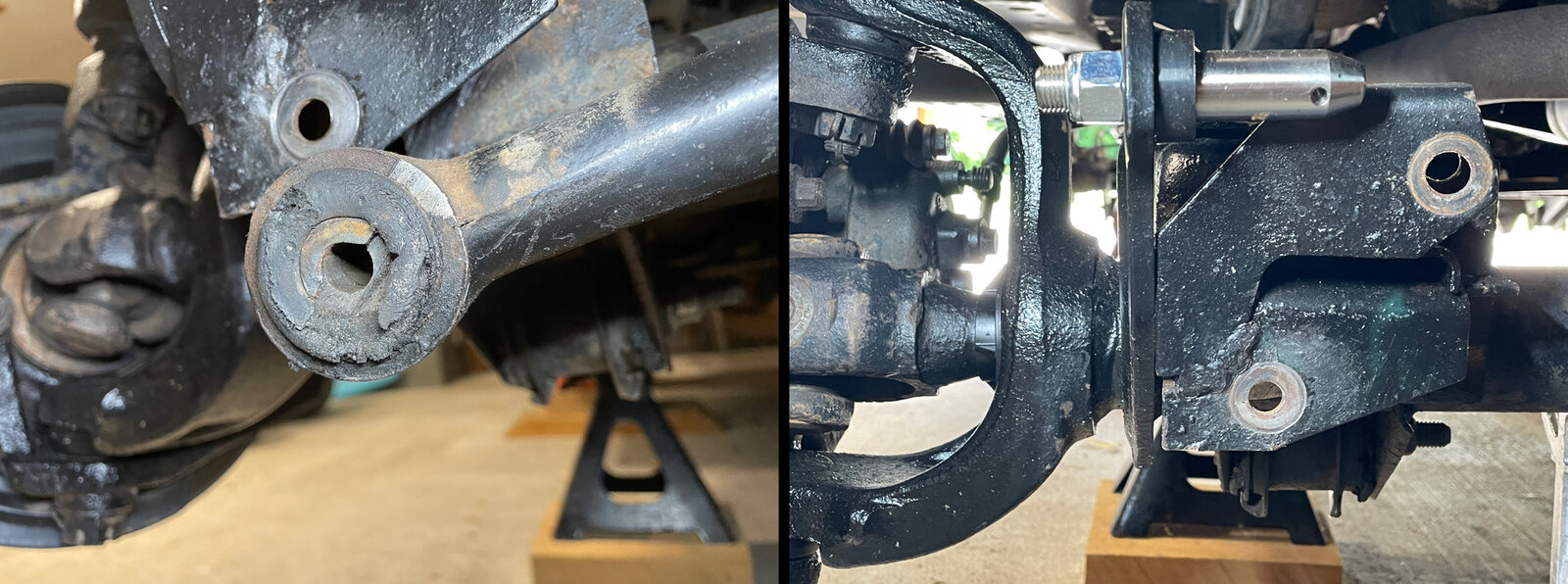

Flag nut broke while removing OEM front track bar. I tried to get a 15mm wrench in from the drivers side but couldn't get it to bite - bolt & nut kept spinning. I am replacing the track bar with an OEM equivalent (Moog DS1235) so ended up cutting through the old rubber bushing, bolt sleeve, and bolt in order to preserve the mount. I tried to be careful with the cutting blade but ended up getting into the backside of the mount a little and the hole is now slightly distorted.

I am not sure if this is an application for a lock washer & regular nut, so ordered the ARP bolt and heavy duty flag nut from @mrblaine. I'd like some advice on the back mount hole. Is it ok to install the new bolt & flag nut despite the back hole being slightly distorted? Will the two sides of the mount still be able to clamp to the end of the bolt sleeve and stop it from moving with the back hole like this?

I am not sure if this is an application for a lock washer & regular nut, so ordered the ARP bolt and heavy duty flag nut from @mrblaine. I'd like some advice on the back mount hole. Is it ok to install the new bolt & flag nut despite the back hole being slightly distorted? Will the two sides of the mount still be able to clamp to the end of the bolt sleeve and stop it from moving with the back hole like this?