Cuttin" it close, but it looks like you might be on schedule to have her ready to run the winter ALCAN?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Higher horses, higher revs & even higher torque, a streetable LJ engine swap

- Thread starter toximus

- Start date

Cuttin" it close, but it looks like you might be on schedule to have her ready to run the winter ALCAN?

Thankfully that's not for another year!

We're undecided on it though. It sounds like during the winter event it's just as many miles driving each day except portions of it are very slow due to road conditions and then you need to make up for it when the roads are nice. And a good portion of the driving is when it's dark outside and taking in the sights made the many miles bearable. Our favorite part was meeting people and it sounds like during the winter nobody visits outside, only at the hotel bar at night, which isn't as much our cup of tea. Coming from WI, I don't understand since anything above 0F is still t-shirt weather.

I still have a dream of driving Alaska in the winter. So I'm sure it'll happen at some point, but not necessarily with the Alcan 5000. Jeep forum adventure ride maybe?

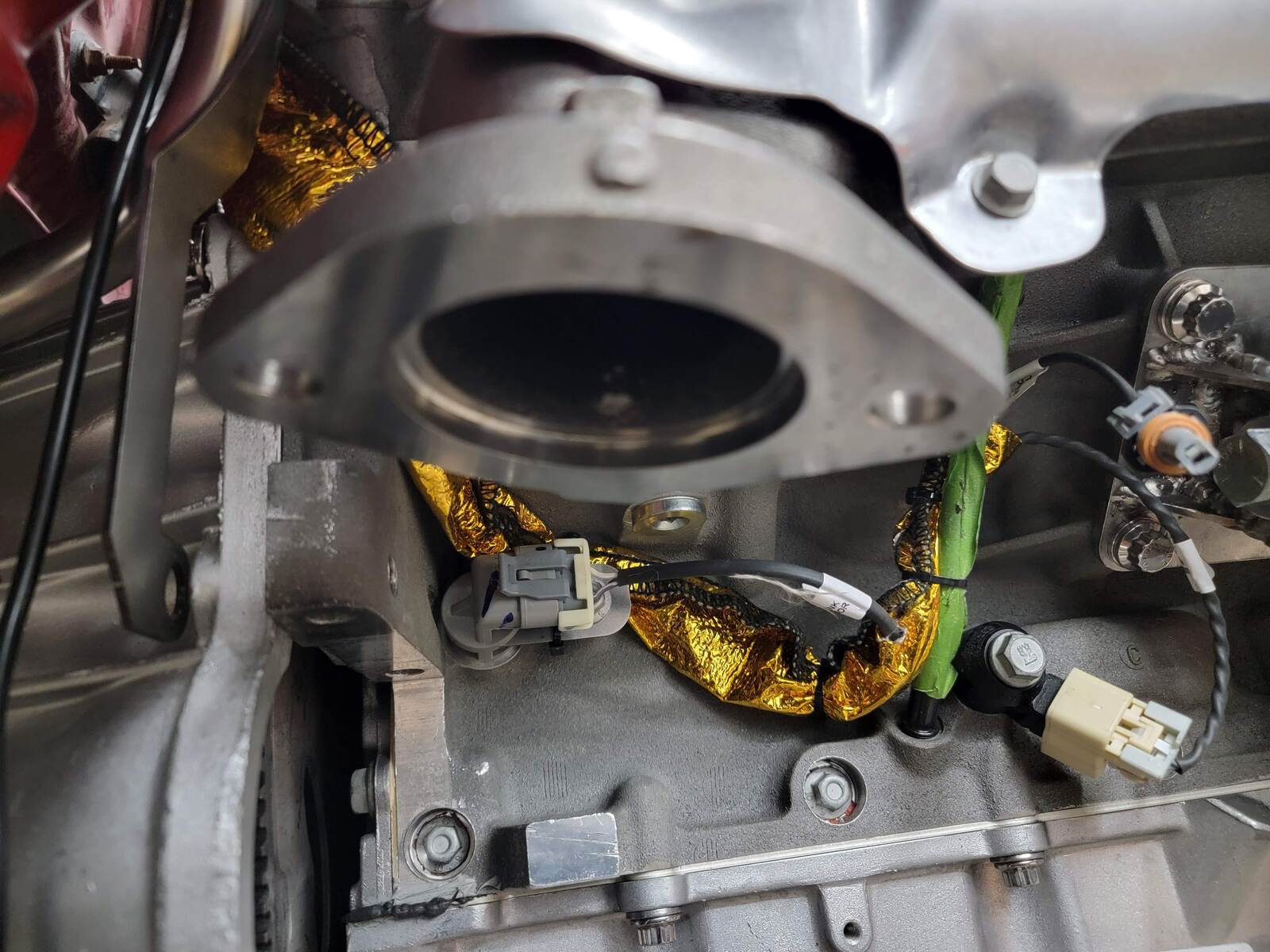

Where wiring will be routed close to the exhaust I depinned connectors and sleeved them in DEI heat sleeving (DEI 10916).

This video shows how to depin many different connector types:

This video shows how to depin many different connector types:

Where wiring will be routed close to the exhaust I depinned connectors and sleeved them in DEI heat sleeving (DEI 10916).

This video shows how to depin many different connector types:

View attachment 366204

View attachment 366205

Wise choice, Tox. I also covered all my wiring that was anywhere near the exhaust. Crazy amount of heat there. I was able to get away with not pulling any connectors by using big enough sleeves, but yours will likely look a bit more finished. Nice work.

Wise choice, Tox. I also covered all my wiring that was anywhere near the exhaust. Crazy amount of heat there. I was able to get away with not pulling any connectors by using big enough sleeves, but yours will likely look a bit more finished. Nice work.

Thanks for the kind words!

Thanks for the kind words!

Thinking about it, I had one of those hard plastic hole plugs in the frame near the passenger header melt - and it was farther away from the header than the wiring. All the wiring has been fine in their cozy little sleeves - so it was definitely worth the effort.

My headers are ceramic coated, which is supposed to help a bit with heat transfer, but they still get pretty damned hot.

Thinking about it, I had one of those hard plastic hole plugs in the frame near the passenger header melt - and it was farther away from the header than the wiring. All the wiring has been fine in their cozy little sleeves - so it was definitely worth the effort.

My headers are ceramic coated, which is supposed to help a bit with heat transfer, but they still get pretty damned hot.

I've been thinking about getting mine coated too along with the pipes.

I've been thinking about getting mine coated too along with the pipes.

My headers & Y-pipe are ceramic coated. I'd thought about doing more of the system but decided not to.

They definitely look cool (see what I did there?), but you know - Hemi. Not sure how they will look with all of your spark plug wires sticking out.I've been thinking about getting mine coated too along with the pipes.

Seriously though, 4 years later they still look like this.

They definitely look cool (see what I did there?), but you know - Hemi. Not sure how they will look with all of your spark plug wires sticking out.

View attachment 366241

Seriously though, 4 years later they still look like this.

The black does look good...

My headers & Y-pipe are ceramic coated. I'd thought about doing more of the system but decided not to.

I just don't know that I want to take it apart again to have them coated.

Maybe I'll have the headers coated and wrap the pipes.

The overflow tank I ordered from Motion Raceworks (32-102) fits the space perfectly! It sure arrived fast!

I made a mounting bracket:

And installed:

(I'll be replacing the plug with a black one.)

I made a mounting bracket:

And installed:

(I'll be replacing the plug with a black one.)

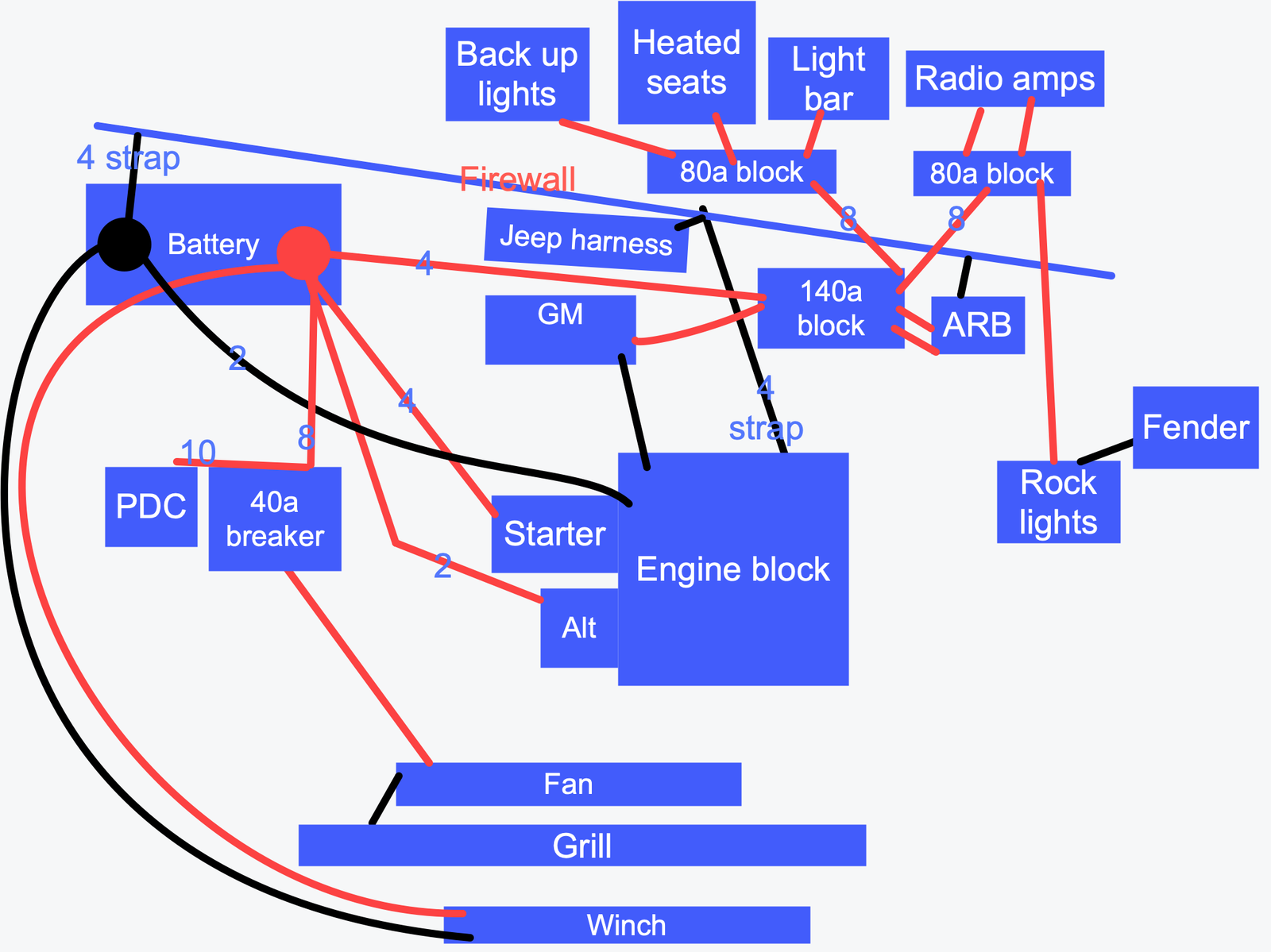

This is my battery cable wiring diagram:

I had previously installed a "big 4" wiring kit since my OEM wires were getting old and tattered. Now that I'm doing it myself and taking care to size things appropriately, I'm finding that I can get by with much smaller and lighter wiring. I've definitely cut out a few pounds of wires so far!

All of my battery cables and lugs are marine grade tinned copper. The split loom is also self extinguishing. I did this in an effort to reduce corrosion and potential fires.

I started crimping cables with the Ancor 703040 crimping tool. If anyone is knowledgeable, I'm curious to know if these are good crimps. They're definitely solid, but I don't like how they smear the lug near a couple of the corners.

I wired the SPAL fan power wire to a 60a resettable breaker from Blue Sea Systems and grounded the fan to the grill.

I had previously installed a "big 4" wiring kit since my OEM wires were getting old and tattered. Now that I'm doing it myself and taking care to size things appropriately, I'm finding that I can get by with much smaller and lighter wiring. I've definitely cut out a few pounds of wires so far!

All of my battery cables and lugs are marine grade tinned copper. The split loom is also self extinguishing. I did this in an effort to reduce corrosion and potential fires.

I started crimping cables with the Ancor 703040 crimping tool. If anyone is knowledgeable, I'm curious to know if these are good crimps. They're definitely solid, but I don't like how they smear the lug near a couple of the corners.

I wired the SPAL fan power wire to a 60a resettable breaker from Blue Sea Systems and grounded the fan to the grill.

That crimp doesn't look too bad, though I think you'll run into problems if you use any heavy duty power lugs compared to the flared lug used in that crimp. The thicker wall thickness will make the smeared edge even worse as it'll be even more over crimped.

I'm not sure if your tool is a whole lot different, but I bought a cub crimper from Quickcable that was for up to 1/0 and it was a giant POS. Not any different than the $50 Amazon special except for color, and it seems a lot of those style of crimpers have dies for metric sized fittings I believe, which is why they tend to over or under crimp stuff. Avoid Quickcable's magnalugs too, they go way overboard on the wall thickness and get over crimped with the same die set that works for the same size Ilsco, AMP, T&B, etc, power lugs. Fuck Quickcable.

I like using the heavier power lugs vs the flared lugs since I finally found a good crimper, Thomas and Betts TBM8. T&B also has a nice app called LugLink, really simple. Just put in the criteria for the fitting you want, and it spits out their part number. I can usually search that on eBay and find NOS fittings for much less than retail.

This writeup was pretty informative too, I would have gone with the FTZ tool, but it was out of stock when I was looking.

https://marinehowto.com/making-your-own-battery-cables/

ebay is the way to go for electrical connectors. Got these 1000 AMP brand ring terminals for $35, should last my entire life and much nicer terminals than anything around town

I'm not sure if your tool is a whole lot different, but I bought a cub crimper from Quickcable that was for up to 1/0 and it was a giant POS. Not any different than the $50 Amazon special except for color, and it seems a lot of those style of crimpers have dies for metric sized fittings I believe, which is why they tend to over or under crimp stuff. Avoid Quickcable's magnalugs too, they go way overboard on the wall thickness and get over crimped with the same die set that works for the same size Ilsco, AMP, T&B, etc, power lugs. Fuck Quickcable.

I like using the heavier power lugs vs the flared lugs since I finally found a good crimper, Thomas and Betts TBM8. T&B also has a nice app called LugLink, really simple. Just put in the criteria for the fitting you want, and it spits out their part number. I can usually search that on eBay and find NOS fittings for much less than retail.

This writeup was pretty informative too, I would have gone with the FTZ tool, but it was out of stock when I was looking.

https://marinehowto.com/making-your-own-battery-cables/

ebay is the way to go for electrical connectors. Got these 1000 AMP brand ring terminals for $35, should last my entire life and much nicer terminals than anything around town

This writeup was pretty informative too, I would have gone with the FTZ tool, but it was out of stock when I was looking.

https://marinehowto.com/making-your-own-battery-cables/

This is really great information! Thanks for sharing it!

This is really great information! Thanks for sharing it!

That article would have been good reading about two weeks ago...before I made new battery cables and overcrimped my terminals

Guess I need to read it so I don't overcrimp mine. I've got to build all new cables for mine.

He hit on a lot of the frustration I felt with my hydraulic crimper from Amazon.

He hit on a lot of the frustration I felt with my hydraulic crimper from Amazon.

I got mine from Amazon also.... We'll see how it does. I might end up buying a NEW tool.

I got mine from Amazon also.... We'll see how it does. I might end up buying a NEW tool.

I’m contemplating to. My motorhome needs new wires as well

Unless you like spending lots of money, you're going to want to buy an OLD tool. AMP Rotacrimp, T&B TBM8, and other industrial grade tools are $1500+ new, but there's several on eBay right now for significantly less. Just make sure you know what you're buying and that it has all the dies you will need if it uses dies.I got mine from Amazon also.... We'll see how it does. I might end up buying a NEW tool.