Decided to convert my front TW driveshaft from boot type to greasable type. Everything was going dandy until the thread tap broke off in the driveshaft. Any ideas on the best way to fix this without having to drill a new hole in the shaft and keeping the threads I already cut? The size is 1/4-28

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How do I un-FUBAR this driveshaft mod?

- Thread starter Tob

- Start date

Decided to convert my front TW driveshaft from boot type to greasable type. Everything was going dandy until the thread tap broke off in the driveshaft. Any ideas on the best way to fix this without having to drill a new hole in the shaft and keeping the threads I already cut? The size is 1/4-28

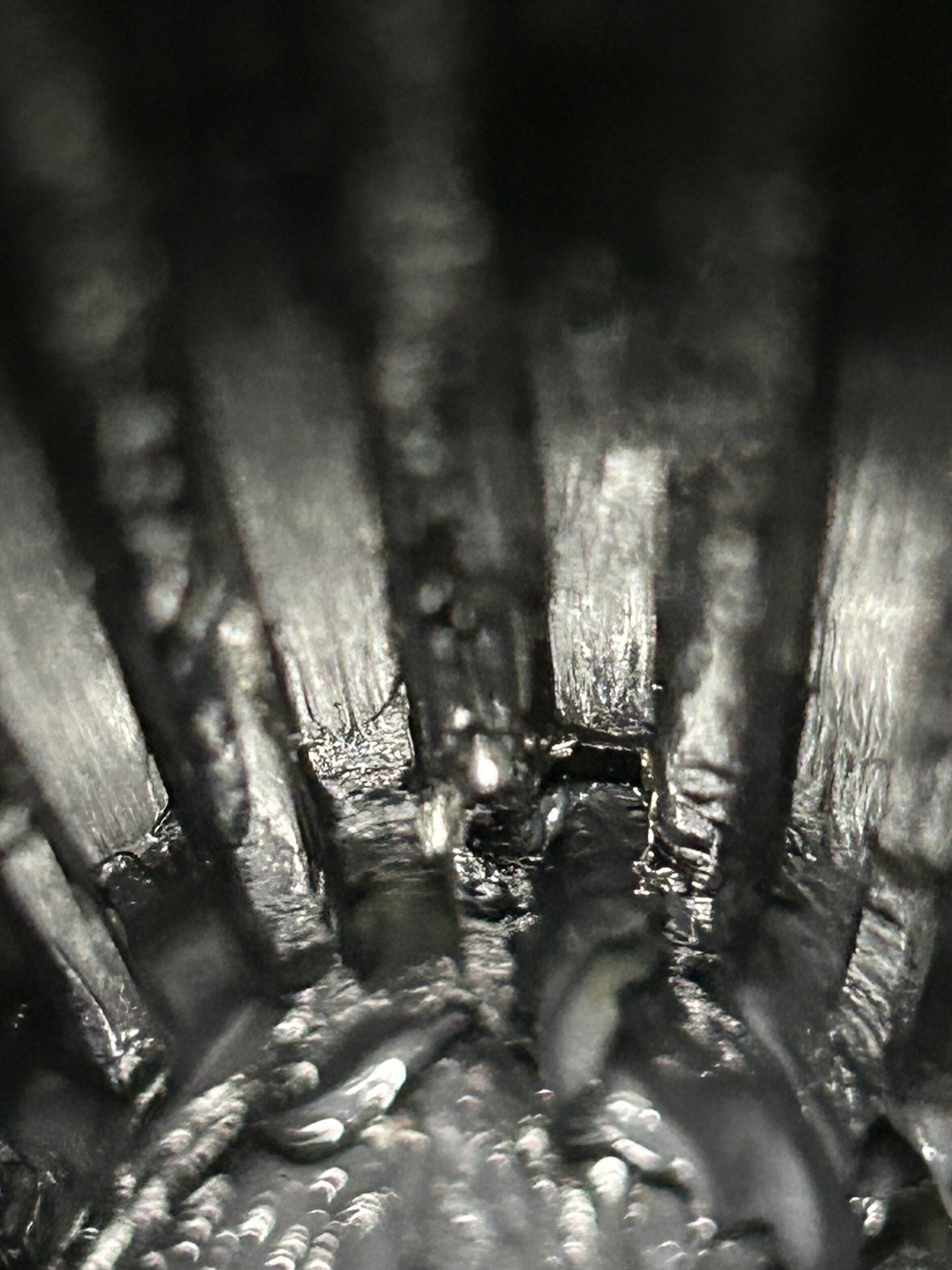

View attachment 515070

Carefully grind it with a 1/8 carbide burr until you can break it in pieces. I use a small pneumatic air grinder but a dremel would work.

a small hammer, a sharp small chisel, a cold beer, and patience, you should be able to back it out by alternating locations as you tap on it. I used to be pretty lucky with this method until I learned not to break off taps, just sayin!

DeltaNu1142

Member

I see the problem: you broke off the tap in a Phillips pattern. If you'd broken it off in a Torx pattern, you could get a better grip on it.

Seriously, that blows. Dremel a slot into it and see if you can get a flat screwdriver in there. Apply torque with some pliers. Dunno if lubing whatever threads are there first with an ATF/acetone mix would help at all, but it couldn't hurt.

Seriously, that blows. Dremel a slot into it and see if you can get a flat screwdriver in there. Apply torque with some pliers. Dunno if lubing whatever threads are there first with an ATF/acetone mix would help at all, but it couldn't hurt.

Those are cool.

Good lord Mr gorilla hands!!! Lay a nut over the broken portion of the tap and weld. Spin the whole mess out and try to use some finesse and gentleness next time lol

Pretty funny post. That's a perfect solution, and funny to ready.

Is it possible to put some needle nose into the gaps of the threader and twist out?

Don’t think so. They would have to be really small and it would take a lot of torque to unthread.

The fact that something like this exists makes me feel slightly less alone in my stupidity.

I think I’ll try breaking it up with a burr or using the a tap extractor. Thanks guys!

The fact that something like this exists makes me feel slightly less alone in my stupidity.

I think I’ll try breaking it up with a burr or using the a tap extractor. Thanks guys!

It doesn't take much to break those small taps. I think you can buy these extractors individually also??

Last edited:

A hammer. A nail punch. Break it into smaller pieces by hammering it hard with the nail punch. Been there. Done this.

I've used those Tap Extractors in the machine shop many times. It will depend on whether the tap is intact or cracked and broken. If cracked and broken, you won't have a good chance. In either case when I was working in the machine shop, the tap extractor worked 2 out of 10 times.

Just a thread resolution post:

I opted for the Walton tap extractor. After soaking with penetrating oil, I got the broken piece out, but it didn’t come out without a fight! Almost took out the extractor fingers.

I suspect the first tap broke because I drilled the hole right between two splines, but not all the way through, and it was stuck between a rock and a hard place. Oh yeah, and because Mr. Gorilla Hands. Bad combo.

After removal, I drilled out the offending stubs, got a new tap, and finished the job.

Thanks for the help everyone!

I opted for the Walton tap extractor. After soaking with penetrating oil, I got the broken piece out, but it didn’t come out without a fight! Almost took out the extractor fingers.

I suspect the first tap broke because I drilled the hole right between two splines, but not all the way through, and it was stuck between a rock and a hard place. Oh yeah, and because Mr. Gorilla Hands. Bad combo.

After removal, I drilled out the offending stubs, got a new tap, and finished the job.

Admittedly, that would’ve been much easier, but that is what I have on the rear driveshaft and I have damaged the grease fitting from rock contact before. I think the fitting will be safer hiding behind the yoke, at least on the front shaft.For future reference though a 211121X Spicer seal has the zerk in it.

Thanks for the help everyone!

I assume for breathing under slip yoke travel? What size hole? I don’t want to open it up too much for grease to get out and contaminants to get in.Also make sure to drill a weep hole in the welch plug in the end of the slip yoke or you will have issues.