P.s. i couldnt find an appropriate thread to put this in. Please move to one that is more appropriate if it isnt  .

.

This is very, very easy. I know alot of people on here might know how to do this, but this is for the people who don’t .

.

Remember to be careful. 110 volts is much more than enough to put you 6 feet under. Especially since a lower voltage like that likes to grab to you and stick on to you. Be careful, especially if doing this while the circuit is powered from the breaker.

Step 1.

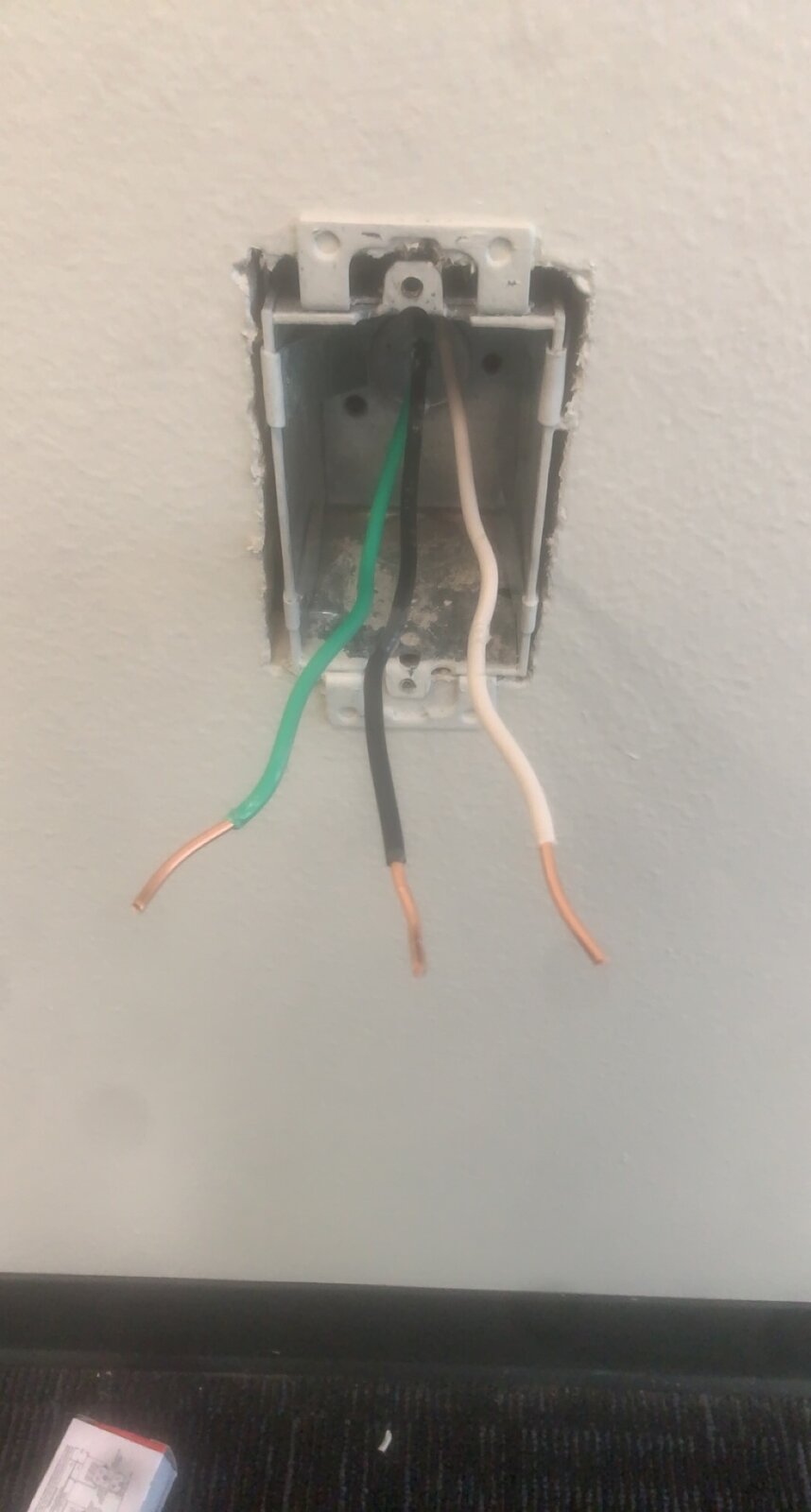

This is for a commercial receptacle, but is the same for your house one. 99% of the time they will have MC ran through the wall in a commercial setting. This comes in a combination of wires such as the picture below. This is 12/2. 12 guage wire with a hot (black) white (neutral) and ground wire (green). Most residential house have romex which is essentially this but it has a rubber coating on it instead of a metal sheathing like mc. Im guessing this has to circle around inspection purposes.

Strip the wire to about this length here.

Step 2.

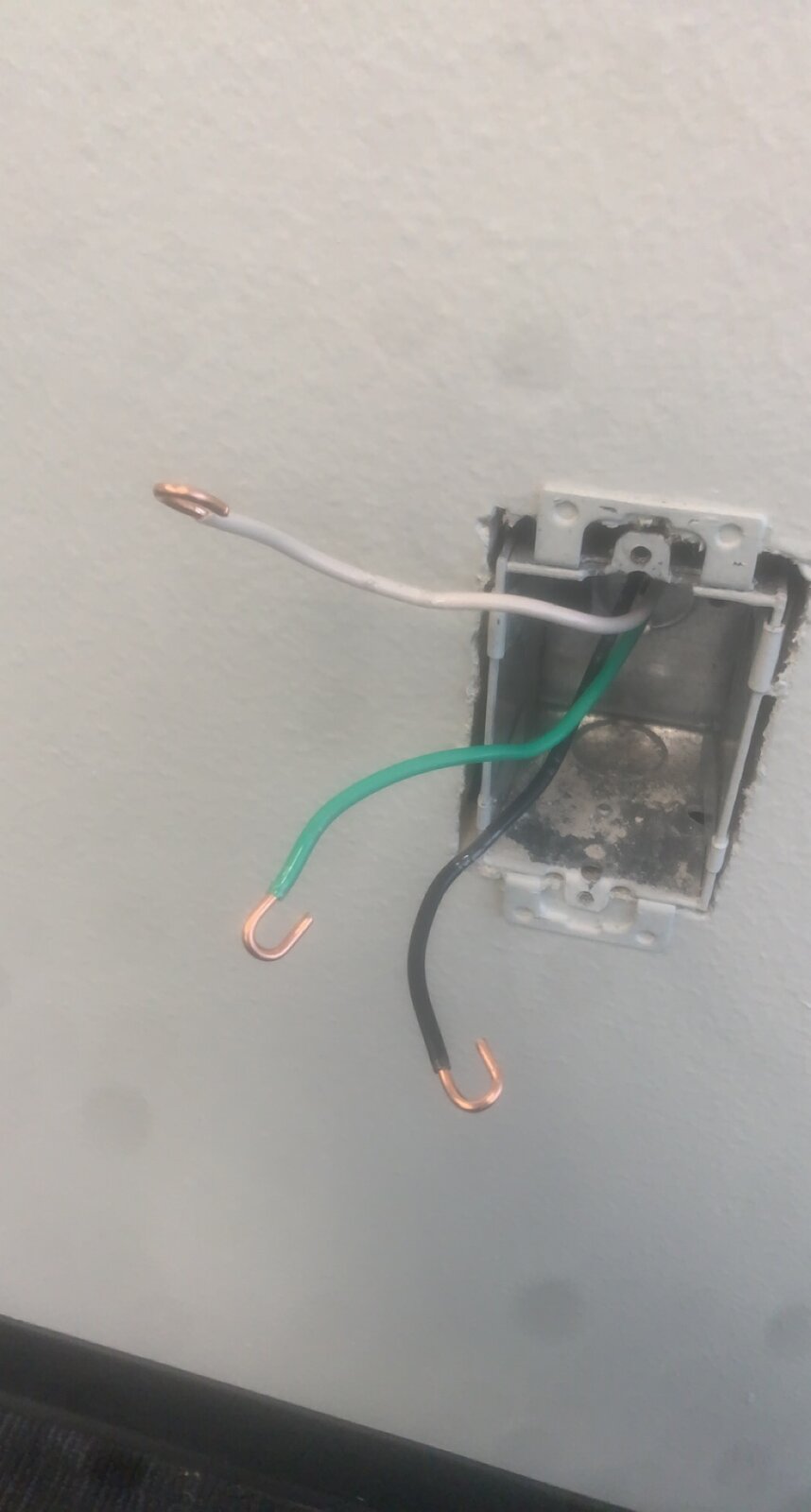

This is known as a ‘J’ hook. In most wire strippers there is a hole around the middle of the wire strippers. Use that to make a j with each of the three wires. You can also use needle nose pliers to do this.

Step 3.

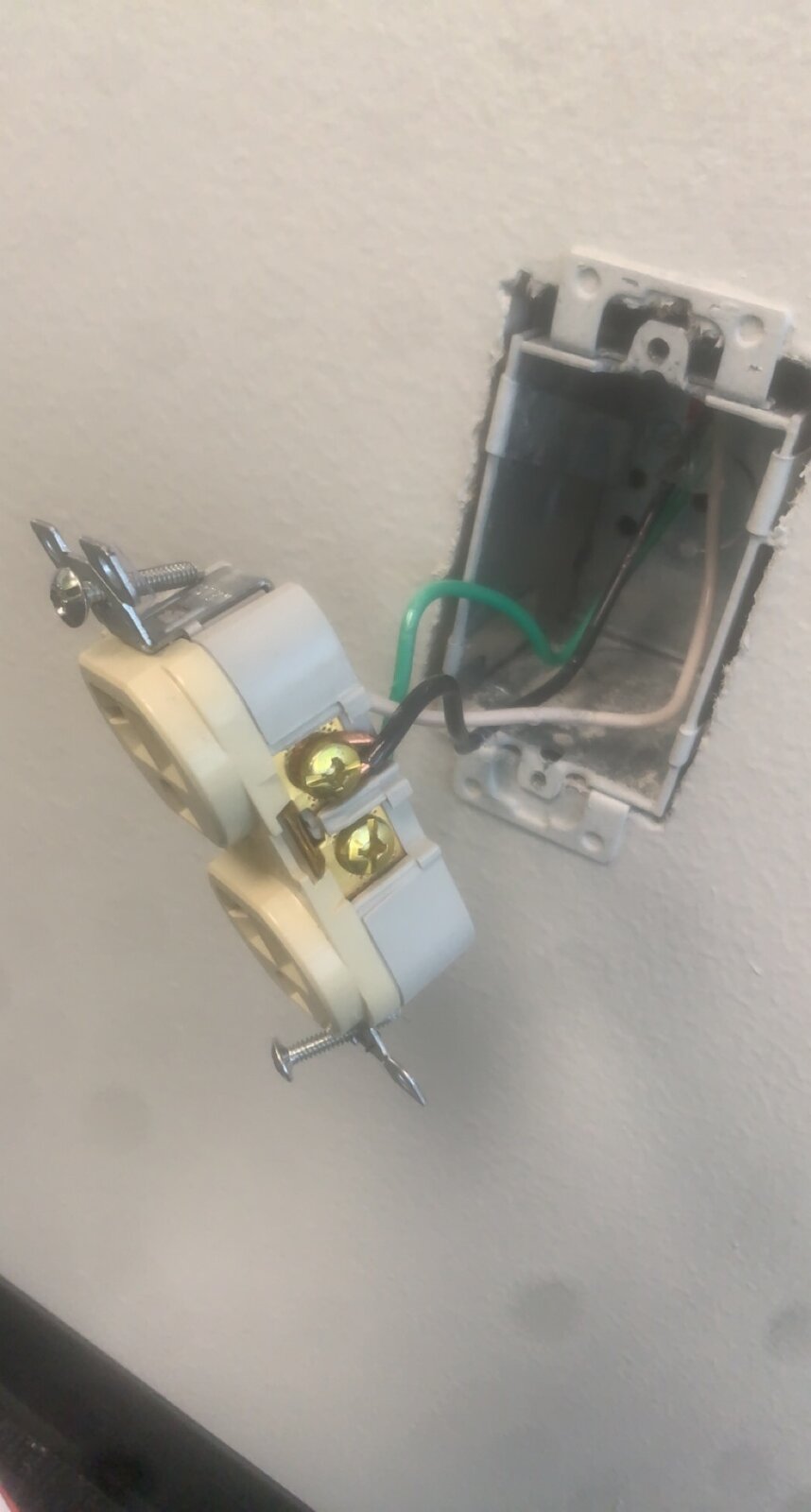

See why they needed to be ‘j’ hooked?

This isn’t a pretty example, but you want you j’s to be tight enough around the screws to where there is no gap contrary to the white neutral wire in the picture.

Green wire goes to the green ground screw at the bottom, the hot wire goes to the gold screw and the neutral goes to the silver screw.

Step 4.

Step 4.

Tighten all the scews and make sure the j is tight around the screw and that none of the copper wire will hit anything, especially the cut in box or the junction box it will be mounted in.

Step 5.

Wrap the ENTIRE receptacle in electrical tape. Electrical tape is an insulator! This is very important. If for some reason you need to take the receptacle out for any reason, and you cant turn its breaker off, the electrical tape can protect the receptacle from hitting the metal box its mounted in and zapping you. I learned this lesson the hard way, while working on one while it was hot.

Step 6.

Screw the receptacle in the box it will be mounted in. There should be 2 screws that come with the receptacle, those are used to screw in the receptacle in the box it will be mounted in.

After you are done screwing the receptacle in, make sure it is straight with the wall and then put the appropriate plate on.

Done!

This is very, very easy. I know alot of people on here might know how to do this, but this is for the people who don’t

Remember to be careful. 110 volts is much more than enough to put you 6 feet under. Especially since a lower voltage like that likes to grab to you and stick on to you. Be careful, especially if doing this while the circuit is powered from the breaker.

Step 1.

This is for a commercial receptacle, but is the same for your house one. 99% of the time they will have MC ran through the wall in a commercial setting. This comes in a combination of wires such as the picture below. This is 12/2. 12 guage wire with a hot (black) white (neutral) and ground wire (green). Most residential house have romex which is essentially this but it has a rubber coating on it instead of a metal sheathing like mc. Im guessing this has to circle around inspection purposes.

Strip the wire to about this length here.

Step 2.

This is known as a ‘J’ hook. In most wire strippers there is a hole around the middle of the wire strippers. Use that to make a j with each of the three wires. You can also use needle nose pliers to do this.

Step 3.

See why they needed to be ‘j’ hooked?

This isn’t a pretty example, but you want you j’s to be tight enough around the screws to where there is no gap contrary to the white neutral wire in the picture.

Green wire goes to the green ground screw at the bottom, the hot wire goes to the gold screw and the neutral goes to the silver screw.

Tighten all the scews and make sure the j is tight around the screw and that none of the copper wire will hit anything, especially the cut in box or the junction box it will be mounted in.

Step 5.

Wrap the ENTIRE receptacle in electrical tape. Electrical tape is an insulator! This is very important. If for some reason you need to take the receptacle out for any reason, and you cant turn its breaker off, the electrical tape can protect the receptacle from hitting the metal box its mounted in and zapping you. I learned this lesson the hard way, while working on one while it was hot.

Step 6.

Screw the receptacle in the box it will be mounted in. There should be 2 screws that come with the receptacle, those are used to screw in the receptacle in the box it will be mounted in.

After you are done screwing the receptacle in, make sure it is straight with the wall and then put the appropriate plate on.

Done!