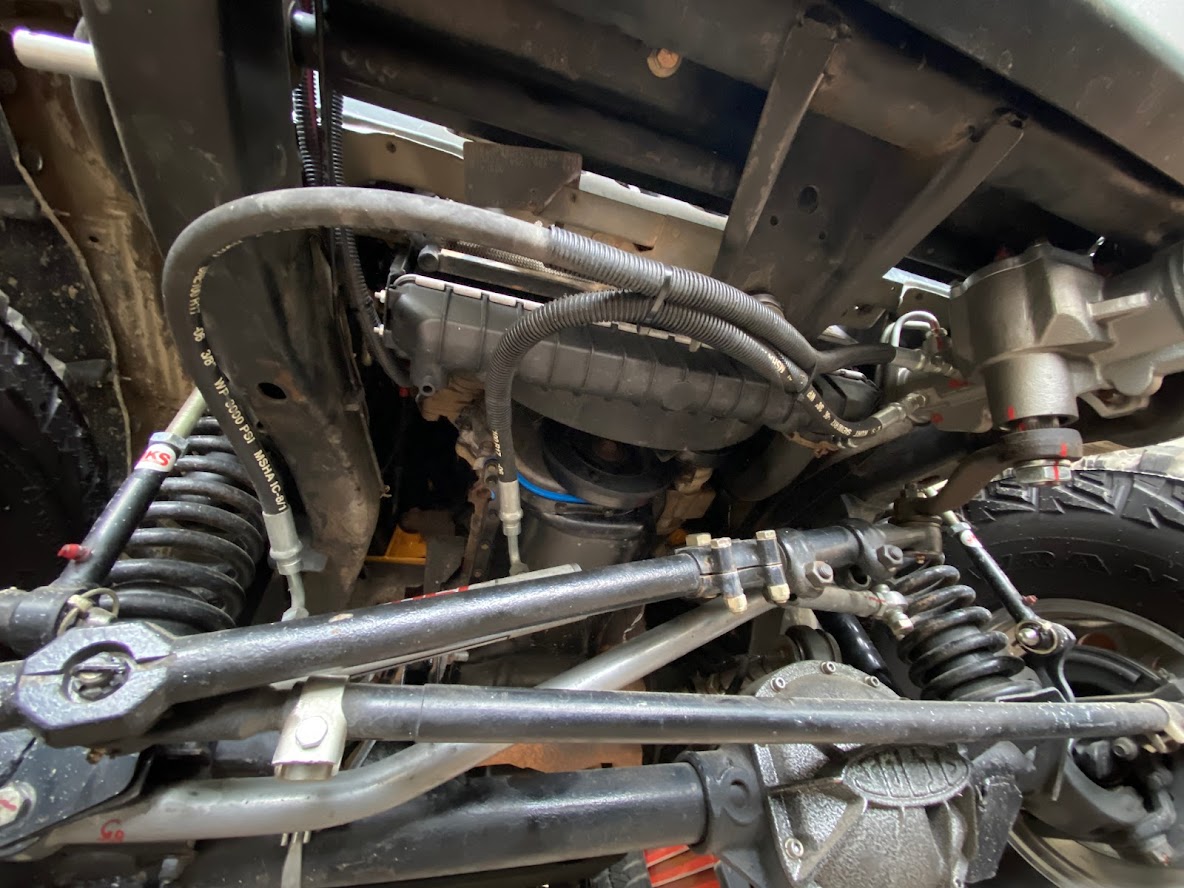

Need some opinions here - for those running hydro-assist on a factory Dana 30 setup, are you having better luck running the lines forward or rearward? I had them rearward (i.e. the 90º points slightly rearward coming off the ram) and that seemed okay. When I finally got the PSC big bore in the LJ, them seemed to fit better coming forward (like the photos below). Going to the rear, they seemed very long and were coming uncomfortably close to the engine/crank pully.

I can't tell if it's the placement of the ports on the big bore are different than the factory Saginaw or if it just looks that way. I'm using the lines that PSC included in their "TJ kit" but they perhaps seem a bit too long (hence the really long Shepherds hook in the routing). I've tweaked the fittings making sure the "tension" is pointing the line in the proper direction, and have used plenty of zip ties, but I constantly deal with the hoses hanging down. I'm afraid they're going to catch on some and cause a massive leak.

Any advice???

I can't tell if it's the placement of the ports on the big bore are different than the factory Saginaw or if it just looks that way. I'm using the lines that PSC included in their "TJ kit" but they perhaps seem a bit too long (hence the really long Shepherds hook in the routing). I've tweaked the fittings making sure the "tension" is pointing the line in the proper direction, and have used plenty of zip ties, but I constantly deal with the hoses hanging down. I'm afraid they're going to catch on some and cause a massive leak.

Any advice???