So I tried to take measurements but it isn't as easy as it sounds. There is a full set of measurements with the molded plastic in place and a full set with it broken off. I'm not ready to break it off just yet until I get the new one. Then I will just send you the whole thing if you want and you can go hands on. Here are some detailed pics. The shift arms ride in the rectangle cut out that is lined with the plastic. I believe this keeps the tolerance tight and prevents chatter. Also, more than likely, reduces friction as the rods slide through them. This piece is so thin and small, I'm not sure machining it would be my approach. I think I would make the whole plate with the tolerance built in. Just a thought. The 5th video is almost up.... Good evening..Thanks for that. Sorry I don't have any advice on the bearing. If you can see that there is no retainers or snap rings holding it in place or staking, your observations are probably correct.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

It has begun: My attempt at rebuilding my 6-speed NSG370

- Thread starter rraulston

- Start date

Darkwing327

TJ Enthusiast

So I tried to take measurements but it isn't as easy as it sounds. There is a full set of measurements with the molded plastic in place and a full set with it broken off. I'm not ready to break it off just yet until I get the new one. Then I will just send you the whole thing if you want and you can go hands on. Here are some detailed pics. The shift arms ride in the rectangle cut out that is lined with the plastic. I believe this keeps the tolerance tight and prevents chatter. Also, more than likely, reduces friction as the rods slide through them. This piece is so thin and small, I'm not sure machining it would be my approach. I think I would make the whole plate with the tolerance built in. Just a thought. The 5th video is almost up.... Good evening..

Thanks again for your efforts. It's not so much that piece that I was thinking of, it is the teflon/plastic slippers on the shift forks themselves. If you have a new shift fork assembly could you get the measurements on those by chance? Thinking a lot of this could be made from bronze or UHMW.

I will be ordering a new shift fork for like $399. All because a .05 cent piece of plastic that is molded on broke. Very common. One could almost use a 3d printer and make something work....

Gotta say, you're videos are awesome. "I don't know what half this chit is." comment in video 2 is hilarious, and sounds like me a lot. My brother (35 year mechanic) shakes his head at me all the time, ha. I have 2 NSGs, strange I like them too, your video is a huge guide, excellent stuff. It's a 106 here in Texas, so you've got me beat, ha.

https://www.moparpartsgiant.com/par...year=2005&submodel=&extra1=&extra2=&filter=()Thanks again for your efforts. It's not so much that piece that I was thinking of, it is the teflon/plastic slippers on the shift forks themselves. If you have a new shift fork assembly could you get the measurements on those by chance? Thinking a lot of this could be made from bronze or UHMW.

I'm curious, I'm looking and found these. If these are the correct pieces, they are $2.62 a piece. These are what come off, correct?

Darkwing327

TJ Enthusiast

I'm curious, I'm looking and found these. If these are the correct pieces, they are $2.62 a piece. These are what come off, correct?

Those are out of the transfer case, which are replaceable it appears. As far as I have ever seen, the ones on the 6 speed are only available bonded to a new shift fork assembly. I have not yet found any information in which someone was successful in building and attaching a new piece, but must be possible as the original piece is bonded.

Good catch, yeah, I just bought the whole fork setup this afternoon, they had 2 in Memphis, a set is on the way. Dam Germans (I’m German, it’s a joke).

Darkwing327

TJ Enthusiast

Good catch, yeah, I just bought the whole fork setup this afternoon, they had 2 in Memphis, a set is on the way. Dam Germans (I’m German, it’s a joke).

Ya, damn Germans...my family too

When you get the new fork, any chance we could chat dimensions etc. There has to be a reasonable solution for both the slippers and the square guidance piece. In all the vids of teardowns I have seen the guide piece is only ever broken on the bottom...and in most cases only cracked. I think the only solution there might be to form and fit a replacement to the lower edge only.

It's not the cost of replacement that is a barrier, I just like a challenge and this, by all accounts, should be a fairly straightforward and doable. I mean c'mon, I have two part metal epoxied a hydraulic housing underwater and it held...somewhere on the shelf of cans I have has to be an adhesive that will hold a piece of plastic/bronze to a piece of aluminum LOL

I will.Ya, damn Germans...my family too

When you get the new fork, any chance we could chat dimensions etc. There has to be a reasonable solution for both the slippers and the square guidance piece. In all the vids of teardowns I have seen the guide piece is only ever broken on the bottom...and in most cases only cracked. I think the only solution there might be to form and fit a replacement to the lower edge only.

It's not the cost of replacement that is a barrier, I just like a challenge and this, by all accounts, should be a fairly straightforward and doable. I mean c'mon, I have two part metal epoxied a hydraulic housing underwater and it held...somewhere on the shelf of cans I have has to be an adhesive that will hold a piece of plastic/bronze to a piece of aluminum LOL

I’ll measure and also I’m keeping the old ones, so I can experiment on them, ha, I kept the input shafts best clutch alignment tool ever

Dam Germans (I’m German, it’s a joke).

German's aren't a protected ethnicity, we're fair game. /politics

I'm really enjoying watching these videos. After my 2 year old goes to bed, me and my 5 year old sometimes log into YouTube and I let him pick a couple of videos to watch. He saw part 4 show up in my subscription feed the other day and asked to watch it, and he paid attention the whole time. I don't spend a lot of time with 5 year olds, but that doesn't seem typical to me and I love it.

When the new one gets here ill get the measurement...Thanks again for your efforts. It's not so much that piece that I was thinking of, it is the teflon/plastic slippers on the shift forks themselves. If you have a new shift fork assembly could you get the measurements on those by chance? Thinking a lot of this could be made from bronze or UHMW.

I haven't yet. Ebay has the best price so far. I just got the 5th gear counter from Rockauto and the input shaft from High Gear Transmissions. I am shopping around saving a $20 where ever I can. Next order will be a 1st gear then a reverse gear. I will then disassemble the main shaft and order syncros. I am thinking about the carbon ones. I called the company and they said the carbon slows down the gears a little faster than brass. That might be what we need for longevity... I know this, my Rubicon, when in 4low and climbing a hill, is impossible not to grind when changing gears. I have since been starting off in 3rd which works for my mild climbing...Where did you order your shift forks, OEM from Chrysler or aftermarket shop somewhere?

Those are the transfer case pads I think...https://www.moparpartsgiant.com/par...year=2005&submodel=&extra1=&extra2=&filter=()

I'm curious, I'm looking and found these. If these are the correct pieces, they are $2.62 a piece. These are what come off, correct?

If you had a $20 (or whatever) replacement part to fix these, you would sell a ton of em.....Ya, damn Germans...my family too

When you get the new fork, any chance we could chat dimensions etc. There has to be a reasonable solution for both the slippers and the square guidance piece. In all the vids of teardowns I have seen the guide piece is only ever broken on the bottom...and in most cases only cracked. I think the only solution there might be to form and fit a replacement to the lower edge only.

It's not the cost of replacement that is a barrier, I just like a challenge and this, by all accounts, should be a fairly straightforward and doable. I mean c'mon, I have two part metal epoxied a hydraulic housing underwater and it held...somewhere on the shelf of cans I have has to be an adhesive that will hold a piece of plastic/bronze to a piece of aluminum LOL

Agree, I was just curious, since they are $2, if they are the same exact size, and if someone was going to try and epoxy them on forks, if these would be the ones to try instead of a 3D printer. I purchased a set, Allstategear has them for close to the ebay price, but at this point I already bought from High Gear in Memphis, and it was a few bucks more. For all the work to change, I figure just put new ones in, ha.Those are the transfer case pads I think...

I'll be watching for your next

Couple more videos uploaded today. Things will get a little slower as I take a few paychecks and source parts.... What sucks is when this is done, I still have a blown engine to figure out. Found an ATK stroker for about $3400. A Golen stroker for 6K plus isnt going to happen... Maybe just do a stock rebuild... I seriously have no idea....

hardtailpan

TJ Enthusiast

ill try to get them tonight. I hit a huge snag yesterday. I cant get the countershaft bearing outer race extracted from the aluminum case. They must have used a locking compound or its super press fit. I'm using a 2lb slide hammer with opposing hooks on the race rim. 100 full blows and it wont move. I started cutting through the race and ran out of cut off disks. Of all the things that I thought would be huge issues, this one wasn't expected...

My guess is you have at this point got the race removed, but if you have not, or for next time, a great solution to this is to put a bead of weld on the inside of the race. The weld cools, an will shrink the race and it will come out easy. Learned this trick from my welder buddy years ago.

My guess is you have at this point got the race removed, but if you have not, or for next time, a great solution to this is to put a bead of weld on the inside of the race. The weld cools, an will shrink the race and it will come out easy. Learned this trick from my welder buddy years ago.

Dang, good tip! I will try that next time. I honestly spent an hour just removing that stupid race!!

Salek_714

Member

You may very well be right. I have nothing to compare it to. I called a specialist today and found out some very interesting information on these transmissions. It will be in my next video....

Rebuilding my transmission today talked to my pops who's been in the transmission repair trade his whole life and he explained to me that a little slop isn't bad. You should see a bit of movement on input shaft due to no load on it from the main shaft bearing. BTW it's funny I found you here I was just asking you questions about your tools on your YouTube channel lol

When you get the new one could you post the measurements of the plastic piece so we can try and make one in the future?

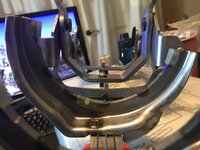

Here are pics I got worn a tape measure on them. There is very, very little to these little dam plastic pieces!

These are brand new Mopar Shifting Forks sent from High Gear. He had 2 in stock.

The plastic/polymer whatever (before someone corrects me, I'm using lay terms) pads on the forks that I measured, the ones on the ends are shorter than the ones in the middle. The ones in the middle are curve formed to fit the contour of the fork bend. I don't know if they are manufactured that way, or soft enough to bend to them. I need these, ha, so I'm not going to tinker with them and screw it up. When I get the old ones next week and look at them, I'll pull and pry or whatever.

Last edited: