HandOverFist

TJ Enthusiast

What is on the seal is not going to matter...it's the outboard side of the cap that will do the most.

Do you think the sealant will adhere to the rubber? Or does it eventually was out. Maybe why they used RTV instead of anaerobic sealant. I’ve not rolled the replacement engine over yet to see what sealant they applied.

What is on the seal is not going to matter...it's the outboard side of the cap that will do the most.

View attachment 366632

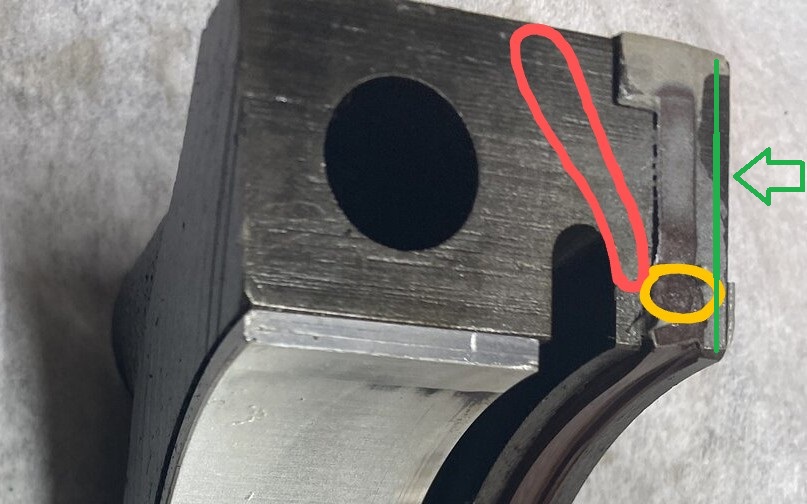

I must be missing something in the pictures. Does the lip on the cap beyond the seal (area in green) not mate to a corresponding machined surface on the block?

We’ll got new engine installed, prelubed engine with drill for a bit, and fired up and did the 20 min break-in. Running conventional 10W-30 pennzoil.

All seems well except what I think is noisy lifters. Very noticeable ticking at idle and increase with rpm. This is after the break-in with engine at op temp.

My other engine did not make this much noise at all, was much quieter. I tried to put my ear with screwdriver to multiple parts of the engine and covers, really hard to tell where it comes from. Even side is hard to really determine.

Not and exhaust leak, and pulled one injector at a time. Other than engine stumble a bit, no charge in noise.

The instructions with this engine stated valves may need adjusted after running. They set the valves at factory at 0 lash then 1 clockwise rotation.

I’ve not messed with the valves or really ever messed with setting valves on hydraulic lifters.

Would like to get some thoughts on how to proceed.

View attachment 371339

Here you go...

Here you go...

I took a look a look and saw no video related. Maybe missing something.

You posted a download instead of a video...