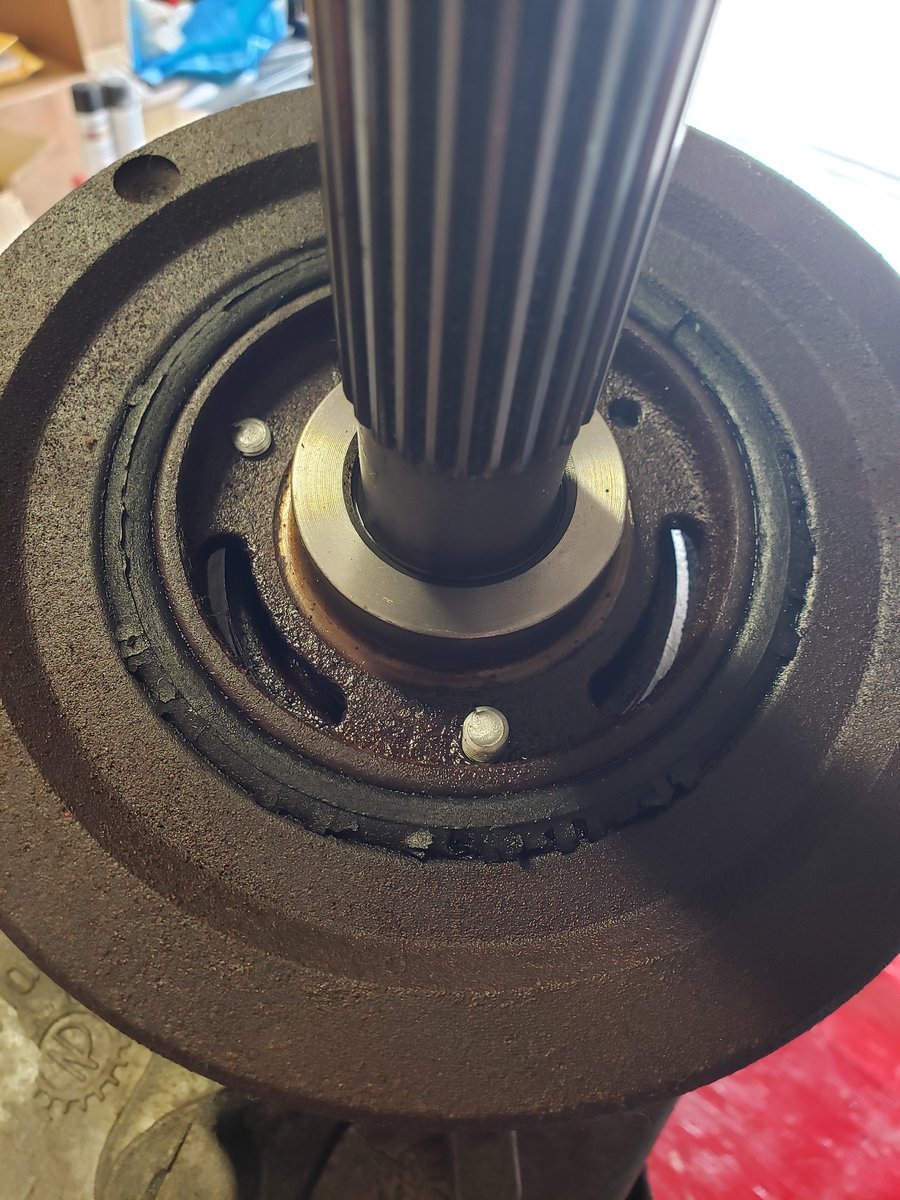

Just started my SYE install and broke two of the three bolts in the balancer. I even soaked all of it in PB Blaster well before starting it. Off to get an easy-out kit and some grade 8 bolts.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Messed up the first step of SYE install

- Thread starter JKLNHYD

- Start date

Yikes. This is something I plan to do in the next two weeks. Any tips on the SYE install overall?

Yikes. This is something I plan to do in the next two weeks. Any tips on the SYE install overall?

Still fighting to get the balancer off. Just broke a bit in the bolt I'm trying to drill out.

got a welder? cut off a couple bolt heads and drill those as big as you can 1 size smaller than that stud, so you can tack them onto those stud tops.

maybe give each 1 a ping on the end with a punch to try and shock it. then the heat from the tacks could just get it loose maybe? without much heat transfer to anything else.

maybe give each 1 a ping on the end with a punch to try and shock it. then the heat from the tacks could just get it loose maybe? without much heat transfer to anything else.

Not enough room to put a nut on them or I would have tried that first.got a welder? cut off a couple bolt heads and drill those as big as you can 1 size smaller than that stud, so you can tack them onto those stud tops.

maybe give each 1 a ping on the end with a punch to try and shock it. then the heat from the tacks could just get it loose maybe? without much heat transfer to anything else.

Got it off. I had one good screw hole left so I put a good amount of tension on one bolt and used two hammers. One to put the claw against the inner metal portion of the balancer and the other to hit that hammer. It broke free and came right off.

Yikes. This is something I plan to do in the next two weeks. Any tips on the SYE install overall?

Once I'm done, I'll post up what I think could be valuable to anyone else attempting to do this themselves.

Run a tap through any time you do something like this. Some vehicles pull brake drums off this way. And there are a few other places this set-up is used. Be sure the tap can turn easily through the threads. Use a better spray lube like Liquid Wrench. Then only use a hardened bolt in them to prevent them twisting off like happened here.

Run a tap through any time you do something like this. Some vehicles pull brake drums off this way. And there are a few other places this set-up is used. Be sure the tap can turn easily through the threads. Use a better spray lube like Liquid Wrench. Then only use a hardened bolt in them to prevent them twisting off like happened here.

I would have but I didn't have a metric tap, only SAE sizes. I learned my lesson on the hardened bolts though!!

If you don't have a real tap and only need to clean and straighten threads you can use a dremel or angle grinder with a thin cut off wheel and slice a slit up the length of the threads on a bolt. Run a slit on both sides of the bolt. This gives room for any crap, gunk, or bent thread to go into.