Yesterday saw me installing the new drivers side engine block mount from Brown Dog Industries. These things are absolute beef and well worth the asking price.

I didn't get many pics due to running into some ( a lot of) issues. The stock brackets mounts to the engine block in 3 locations... The Brown Dog bracket mounts to the block in 7 locations. That's if all of your mounting bosses are in good working order. Mine were not.

The above are pics of the previous owners attempts at welding and fabricating a engine mount and you will understand why i ran into problems. Even my French Bulldog "Pig" knows this sucks

My mounting bosses had issues to say the least.

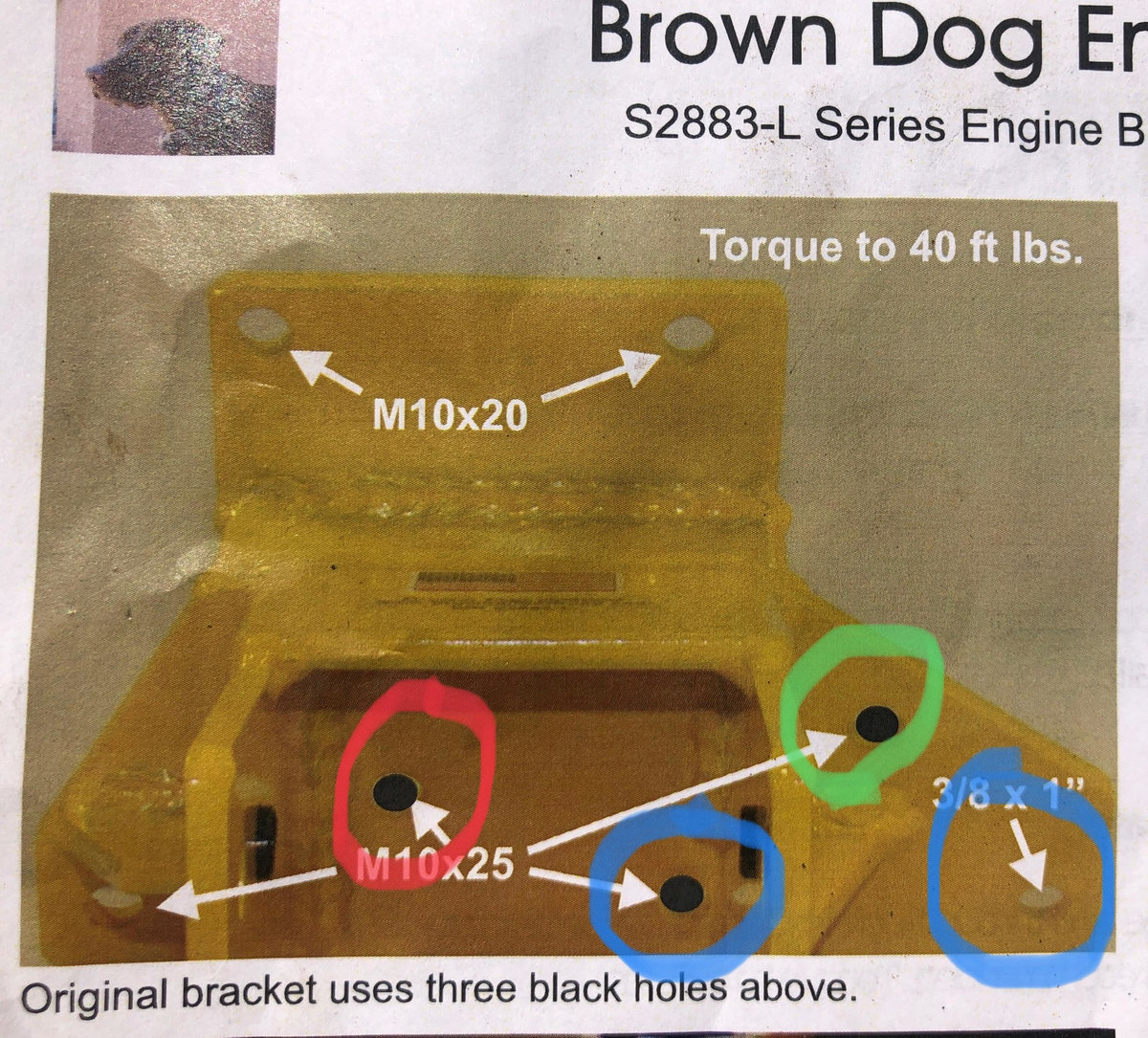

Here's a pic of the mount from Brown dogs website.

The three un-circled mounting holes worked fine with zero issues.

The red circled hole represents where the cast had failed and the boss was broken off the block.

The green represents a boss that had the shank of a sheared bolt stuck in it.

The blue represent bosses that had been stripped out.

So I torqued the 3 good bosses to spec.

On the the red circle, I was able to capture the last 3-4 threads that were still present in the broken boss. Red loctite and torque to spec but will it hold?

The green circle I left empty due to the broken off bolt.

The inside blue circle, the stripped threads would almost hold torque before "releasing". I think the previous owner had too long a bolt and bottomed it out, thereby stripping the threads. I used a ton of red loctite and tightened it to the point of just before it released.

The outside blue circle, I did the same but it wasn't really near torque so I think its close to useless.

Brown dog says you can just use 4 mounting holes and you'll be good. But I think they mean using the 4 new holes which are spread out and not the 3 originals.

I don't know if this will hold or not. The plan right now is to drive it and check it after every trip.

If it loosens then i am going to try this thread repair kit from loctite

https://www.grainger.com/product/LOCTITE-12-9mL-Gray-Stripped-Thread-1YDZ5

Last resort and one I'll do anything to avoid is pull the engine and tap/re-thread or helicoil the 2 stripped bosses and remove the broken bolt from the 3rd.

There's no way to do it with the engine in the vehicle. But I'd hate top have to go this route.

Anyone have any other ideas?

I didn't get many pics due to running into some ( a lot of) issues. The stock brackets mounts to the engine block in 3 locations... The Brown Dog bracket mounts to the block in 7 locations. That's if all of your mounting bosses are in good working order. Mine were not.

The above are pics of the previous owners attempts at welding and fabricating a engine mount and you will understand why i ran into problems. Even my French Bulldog "Pig" knows this sucks

My mounting bosses had issues to say the least.

Here's a pic of the mount from Brown dogs website.

The three un-circled mounting holes worked fine with zero issues.

The red circled hole represents where the cast had failed and the boss was broken off the block.

The green represents a boss that had the shank of a sheared bolt stuck in it.

The blue represent bosses that had been stripped out.

So I torqued the 3 good bosses to spec.

On the the red circle, I was able to capture the last 3-4 threads that were still present in the broken boss. Red loctite and torque to spec but will it hold?

The green circle I left empty due to the broken off bolt.

The inside blue circle, the stripped threads would almost hold torque before "releasing". I think the previous owner had too long a bolt and bottomed it out, thereby stripping the threads. I used a ton of red loctite and tightened it to the point of just before it released.

The outside blue circle, I did the same but it wasn't really near torque so I think its close to useless.

Brown dog says you can just use 4 mounting holes and you'll be good. But I think they mean using the 4 new holes which are spread out and not the 3 originals.

I don't know if this will hold or not. The plan right now is to drive it and check it after every trip.

If it loosens then i am going to try this thread repair kit from loctite

https://www.grainger.com/product/LOCTITE-12-9mL-Gray-Stripped-Thread-1YDZ5

Last resort and one I'll do anything to avoid is pull the engine and tap/re-thread or helicoil the 2 stripped bosses and remove the broken bolt from the 3rd.

There's no way to do it with the engine in the vehicle. But I'd hate top have to go this route.

Anyone have any other ideas?

Last edited: