After making the cuts, I immediately wished that I had done this sooner. The cutoffs make perfect 3/8" tabs, and would have worked well when I built the tabs for the rear sway bar / limiting strap brackets. Oh well, saved for a future project.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nashville TJ's Build - Continued

- Thread starter NashvilleTJ

- Start date

If you are that bored I got a ton of stuff that needs to get done.....

Rims are suppose to be here tomorrow.

Rims are suppose to be here tomorrow.

Well, after weather excuse upon weather excuse, Fedex finally showed up today with the Golden Hubs and bearings. Man, these things are beefy.

They dwarf the half ton stuff.

Funny thing, I had advertised the Ford F-350 hubs I purchased mistakenly on Ebay, and sold them today as well - for just about what I paid for them. A nice coincidence.

So tonight I took a few minutes and greased up the bearings, installed the seals, and torqued them down to the spindles.

The bad news is that I ordered some new front brake lines from Kartek a couple of weeks ago, and since Snowmageddon UPS apparently can't locate the package - so I'm back on hold until that gets resolved one way or another.

They dwarf the half ton stuff.

Funny thing, I had advertised the Ford F-350 hubs I purchased mistakenly on Ebay, and sold them today as well - for just about what I paid for them. A nice coincidence.

So tonight I took a few minutes and greased up the bearings, installed the seals, and torqued them down to the spindles.

The bad news is that I ordered some new front brake lines from Kartek a couple of weeks ago, and since Snowmageddon UPS apparently can't locate the package - so I'm back on hold until that gets resolved one way or another.

I spent a little time on the rig today. It's been so long since I took apart the locking hubs, I had to spend a little time verifying where everything goes. But, I was able to lay all the pieces out in order...

...and stuff 'em back in:

And I got a little satisfaction bolting on the brake caliper for the last time.

Installed the spacer, and the passenger side was done.

(Queue the music from Jaws....)

...and stuff 'em back in:

And I got a little satisfaction bolting on the brake caliper for the last time.

Installed the spacer, and the passenger side was done.

(Queue the music from Jaws....)

Last edited:

I knew it was going too easily...

So I go to install the driver's side hub - and the main gear which engages with the hub is tight. Too tight to move freely, which it has to do to engage and disengage. I'm so done with Dynatrac - the teeth in the Golden Hub were clearly milled a few thou too shallow. I could force it in, but it would not slide back and forth.

So I spent a little time and took the quick way out. I ran a file over each of the 55 teeth on the gear a few times, and that took care of it.

I was certainly not expecting that, but it was a fairly quick fix. I'll just have to remember that if I ever have to replace that hub or the locker.

But, it's done and back together. All I needed were the brake lines....

So I go to install the driver's side hub - and the main gear which engages with the hub is tight. Too tight to move freely, which it has to do to engage and disengage. I'm so done with Dynatrac - the teeth in the Golden Hub were clearly milled a few thou too shallow. I could force it in, but it would not slide back and forth.

So I spent a little time and took the quick way out. I ran a file over each of the 55 teeth on the gear a few times, and that took care of it.

I was certainly not expecting that, but it was a fairly quick fix. I'll just have to remember that if I ever have to replace that hub or the locker.

But, it's done and back together. All I needed were the brake lines....

Last edited:

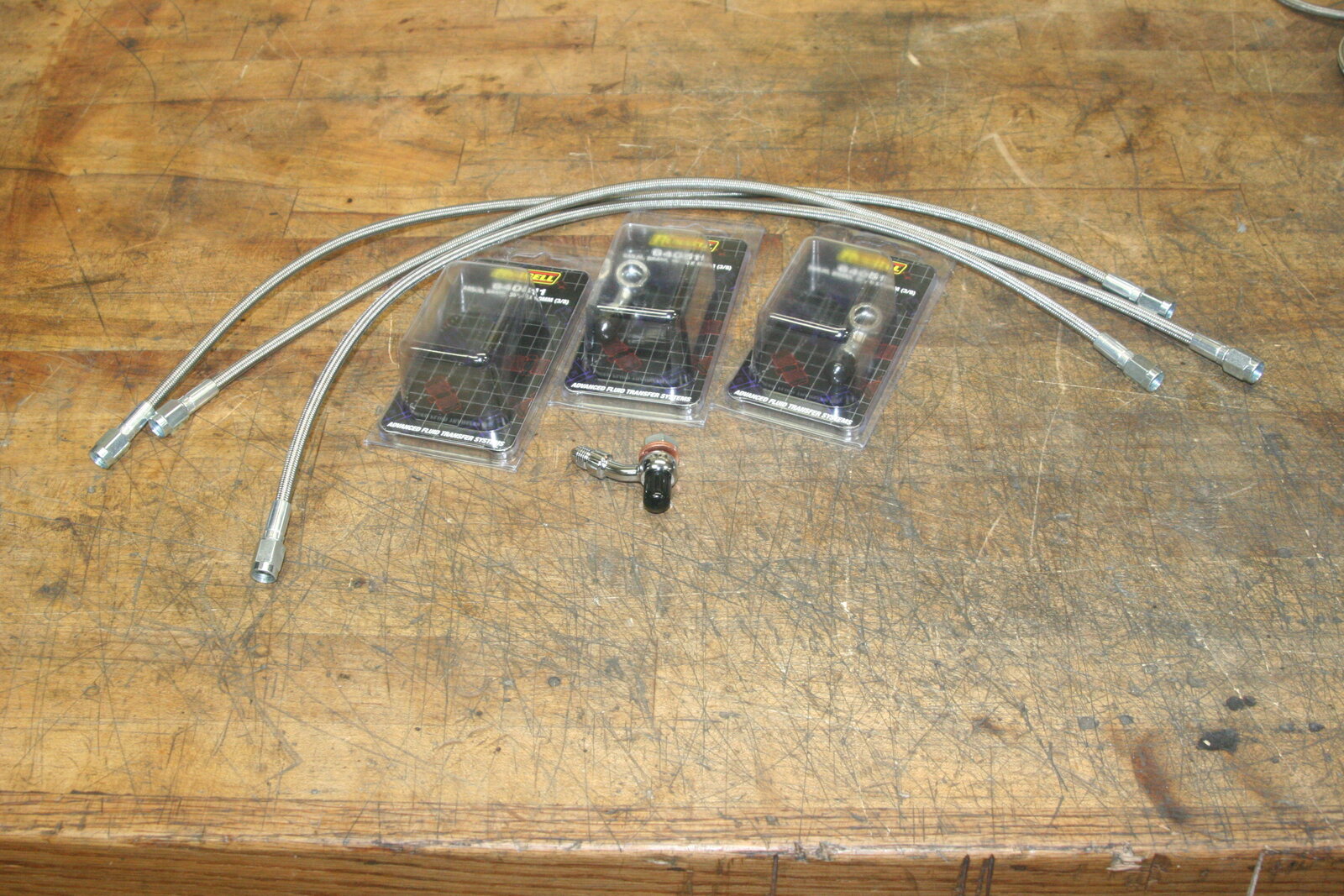

Early afternoon, I get a text from UPS that tells me the Kartek stuff was delivered. A little excited, I tell myself I'm driving the rig by 5...

But it was not to be. It took me about two minutes to realize that I had ordered the wrong banjo fitting. Instead of a -3 male fitting, I inadvertently ordered a reusable PTFE hose fitting. I checked with my local speed shop and they have the fitting, so I'll head up there first thing in the morning and pick them up.

And this time, I'm not counting my chickens....

But it was not to be. It took me about two minutes to realize that I had ordered the wrong banjo fitting. Instead of a -3 male fitting, I inadvertently ordered a reusable PTFE hose fitting. I checked with my local speed shop and they have the fitting, so I'll head up there first thing in the morning and pick them up.

And this time, I'm not counting my chickens....

First thing this morning I headed up to TN Speed Sports up in Madison - about 45 minutes north of me - and picked up the correct banjo fittings. I should have done this to start with...

Then it was short work getting the lines installed, and having my wife help me bleed the brakes.

Then it was short work getting the lines installed, and having my wife help me bleed the brakes.

And then it was out for a long awaited test drive. Everything worked well. No vibes and good brakes. I took some time to follow the break-in procedure for the new pads. It was certainly nice to be behind the wheel once again.

It's sitting a little high in the rear, so I'll likely raise the front just a bit to level it out.

It's sitting a little high in the rear, so I'll likely raise the front just a bit to level it out.

And since everything went well with the test drive, I threw the tire carrier back on. And whadda ya know - it fit.

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

Feels good don't it!?!And then it was out for a long awaited test drive. Everything worked well. No vibes and good brakes. I took some time to follow the break-in procedure for the new pads. It was certainly nice to be behind the wheel once again.

It's sitting a little high in the rear, so I'll likely raise the front just a bit to level it out.

View attachment 229551

First thing on Saturday I leveled out the rig just a bit. I had about and inch too much rake between the front and the rear after doing the 14 bolt. I thought I had duplicated the lower shock mounts similar to the '60, but I must had missed it by a bit because the rear was sitting higher by an inch.

Anyway, I lowered the rear coils a 1/4" - that's all I could get out of it without the springs starting to unseat at full droop - and raised the front 3/4". Here it is.

Now I will feel better about driving it down to the mall.

Anyway, I lowered the rear coils a 1/4" - that's all I could get out of it without the springs starting to unseat at full droop - and raised the front 3/4". Here it is.

Now I will feel better about driving it down to the mall.

Last edited:

And right on into my next project. I'm giving some thought to heading out to Moab in late April with the TJ Fest group, and they've decided to go with GMRS for mobile communication. I have a Cobra 75 CB which I still use, so my plan is to add an additional GMRS unit.

After some research, I picked up a Midland MTX275 which has all the controls in the mike so the main unit can be mounted under the dash - just like the Cobra.

It's an OK unit with 15 watts, but I mainly bought it for it's unique form factor. Not a lot of room in the rig, so I needed the remote mount.

I also picked up a good antenna. It's a high-end 5/8 wave GMRS unit from Laird. I spent nearly as much on the antenna, cable and fitting as I did on the Midland - but's it's always the antenna which makes or breaks the performance.

After some research, I picked up a Midland MTX275 which has all the controls in the mike so the main unit can be mounted under the dash - just like the Cobra.

It's an OK unit with 15 watts, but I mainly bought it for it's unique form factor. Not a lot of room in the rig, so I needed the remote mount.

I also picked up a good antenna. It's a high-end 5/8 wave GMRS unit from Laird. I spent nearly as much on the antenna, cable and fitting as I did on the Midland - but's it's always the antenna which makes or breaks the performance.

Last edited:

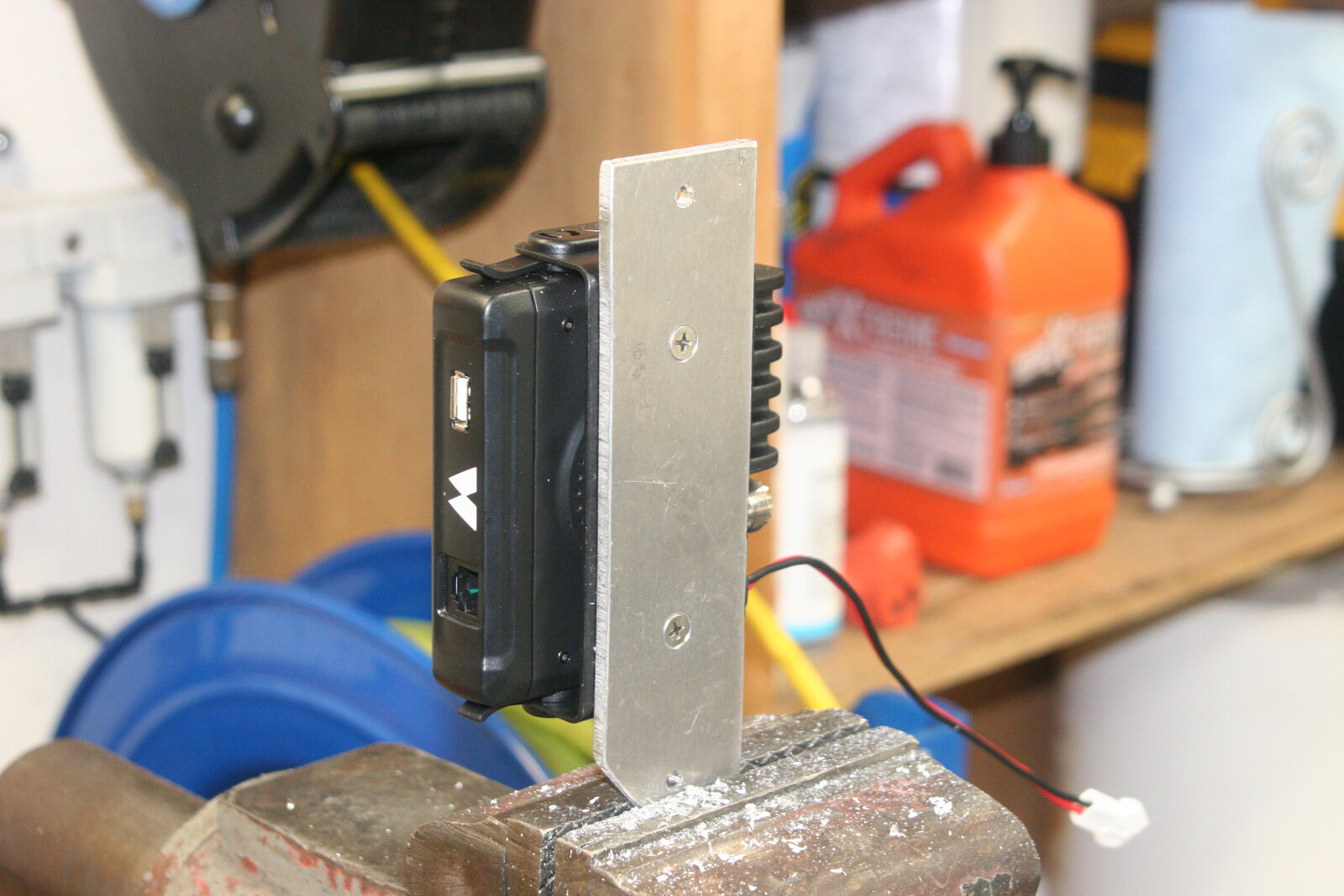

The remote unit comes with a sliding mount, but since I was planning to mount it on the left side of the foot well there was not enough room to slide the unit enough to install or remove it.

So I built a quick bracket out of aluminum which attaches to the body with two screws.

Here it is installed right next to the Cobra unit. This way I can easily swap my external speaker back and forth just by switching the plug.

So I built a quick bracket out of aluminum which attaches to the body with two screws.

Here it is installed right next to the Cobra unit. This way I can easily swap my external speaker back and forth just by switching the plug.

The mike attaches to the remote unit using a cat5 cable, so I added a cat5 connector on the side of the console and ran a cat5 jumper back to the remote unit.

My CB antenna is mounted on the rear driver side of the rig, so I located the GMRS antenna on the opposite side. I cut and bent a bracket which attaches to the rig with 5/16" stainless countersunk allen head bolts. I also removed the paint from the bracket and the inside of the body to ensure a good ground.

I ran the cable through a rubber grommet to the interior of the rig and installed the antenna...

...and then routed the cable up the passenger side of the rig over to the remote unit.

...and then routed the cable up the passenger side of the rig over to the remote unit.

Now, since I'm as much of a hack with communications as I am with everything else I do on the Jeep, I ordered two solder connectors and two crimp style connectors to complete the cable - since I knew I was going to mess up a few on the way to completion.

This turned out to be easy through, and I got it on the first try. If I had ordered only one, I definitely would have screwed it up.

I only know enough to be dangerous with this stuff, but I did pick up a UHF SWR meter to tune the antenna to the radio. I had a meter for the CB band, but it does not work on the GMRS band. My first reading was a 1.5 SWR.

I shortened the antenna, but the best SWR I could get was 1.3. Everything I've read says you want to be under two, but I was hoping for better. We will just have to see how it performs out in the real world.

This turned out to be easy through, and I got it on the first try. If I had ordered only one, I definitely would have screwed it up.

I only know enough to be dangerous with this stuff, but I did pick up a UHF SWR meter to tune the antenna to the radio. I had a meter for the CB band, but it does not work on the GMRS band. My first reading was a 1.5 SWR.

I shortened the antenna, but the best SWR I could get was 1.3. Everything I've read says you want to be under two, but I was hoping for better. We will just have to see how it performs out in the real world.

A short while ago Boom asked me to post up some info on how I built my redneck cutting brakes, so here is a quick post describing same.Ya please more info is always better and not many tjs have turning brakes. Maybe include how often and hope you use it?

I ordered a stock parking brake assembly with cables from Davey's Jeeps, and with a little figerin', cypherin', cuttin' and weldin', I connected the two levers onto the single stock mount. I angled and spaced them apart enough so that they can easily be operated separately.

The only modification I had to make to the body was to allow the two cables to pass through, and merge the two grommets together to make a weatherproof seal.

Last edited: