The new one is on the left? I'm not familiar with how the Dana 35 goes together...thanks , I posted it this morning …..Dana 35 pinion crush sleeve different? My concern is the race sitting in groove’s. I don’t know what kind of pressure the bearings are under at that part of the pinion. Thanks for looking.

Rick

View attachment 329822

View attachment 329823

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Re-gear, take two

- Thread starter Mike_H

- Start date

I think I'm done. Got 0.007"backlash and a pinion depth of 0.059"

Where is @hosejockey61I think I'm done. Got 0.007"backlash and a pinion depth of 0.059"View attachment 329825View attachment 329826

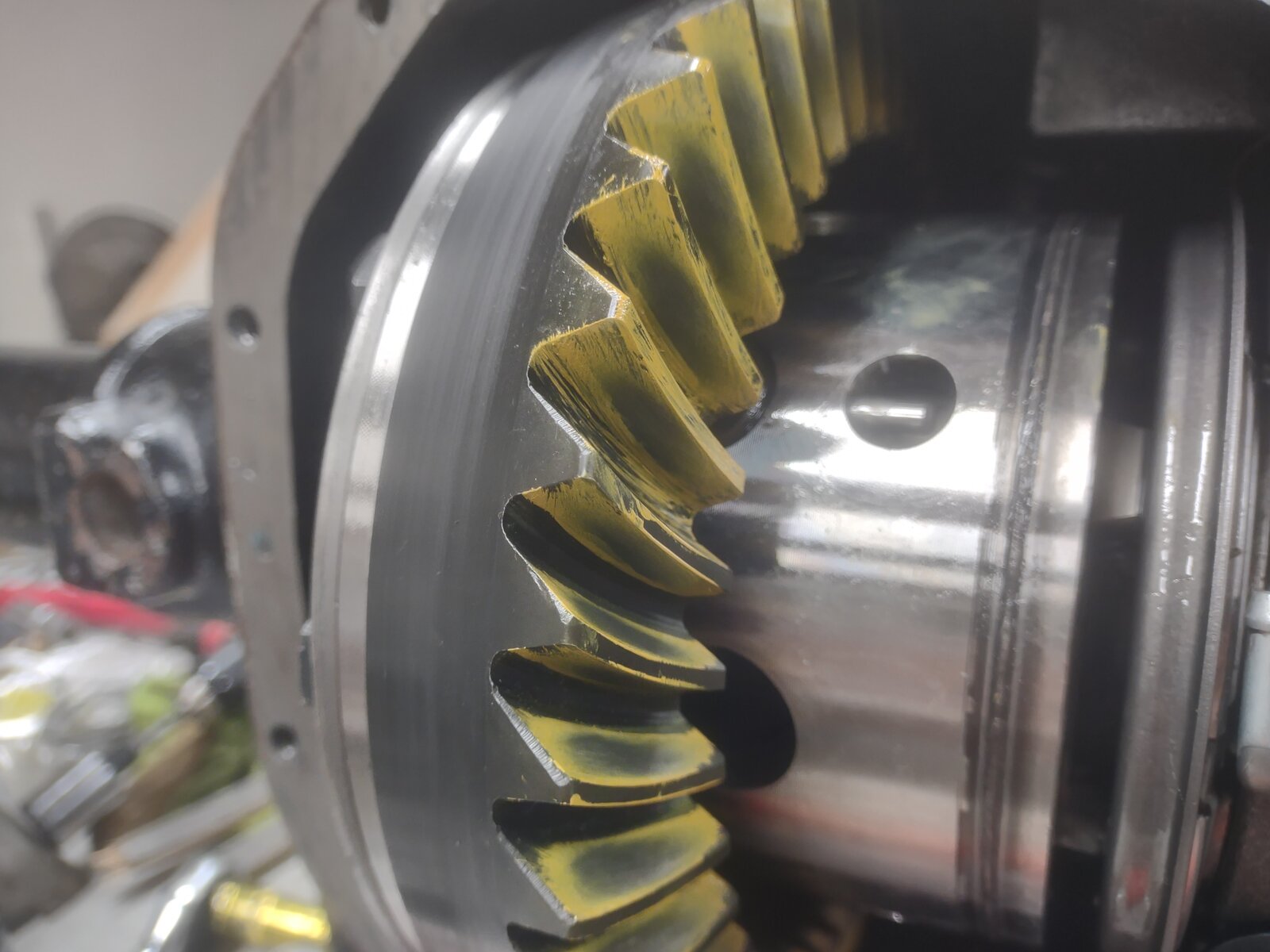

So... After talking with some guys on the Facebook group, I decided to look at the pinion. It's like reading the ring, but opposite. Anyway, at this setup, the pinion was reading shallow.

So, I went back a bit to 0.063 thou pinion depth and the pattern on the pinion reads really well. Nice even contact across the tooth and the pattern on the ring about half bad either.

I still want to tweak my backlash (this is 0.010") but it's nearly done. This new gearset from revolution had been way more difficult to setup than the used yukons I had before. Not that I'm recommending used gears... But this one was challenging.

So, I went back a bit to 0.063 thou pinion depth and the pattern on the pinion reads really well. Nice even contact across the tooth and the pattern on the ring about half bad either.

I still want to tweak my backlash (this is 0.010") but it's nearly done. This new gearset from revolution had been way more difficult to setup than the used yukons I had before. Not that I'm recommending used gears... But this one was challenging.

Mike, the new one is on the right and the bearing surface area is blended into the splines. The crush sleeve is the old one and just there to illustrate the amount of room it will leave for the bearing to distribute drive force. Might be ok but it’s different and as a former aircraft mechanic that makes me wonder.The new one is on the left? I'm not familiar with how the Dana 35 goes together...

Oh dont wander off into general population there!In Jamaica.... my phone screen went out... can't see shit

He will stand out like a sore thumb, no need to worry.Oh dont wander off into general population there!

Pics or it didn’t happen!In Jamaica.... my phone screen went out... can't see shit

(Ahh - the Jamaica part, not the phone part…)

Oddly, I have found Revo gears super easy to setup as they appear to do a nice job of checking mesh and matching pairs than any of the new Yukons sets I've installed the past 2 years. Hell, even a set of RC gears went smoother than any of the ~3 Yukons I've installed most recently...I still want to tweak my backlash (this is 0.010") but it's nearly done. This new gearset from revolution had been way more difficult to setup than the used yukons I had before. Not that I'm recommending used gears... But this one was challenging.

I suspected you'd end up ~0.062" for pinion and the pattern would clean up once you got BL in line. Should be close now - nice work!

Pics or it didn’t happen!

(Ahh - the Jamaica part, not the phone part…)

Final pattern...It still looks a touch deep to me on the drive side, but I'm going with it, based on the pinion pattern.

Also, I figured out the issue with the first set-up and why I roasted the pinion bearing...there is something about this housing and inner bearing race combination that sets up much differently than my set-up bearing. I found it again last night when I was doing final assembly and my rotating torque went high (like 50 in-lbs). I reset my preload shims and got it back down to 20 in-lbs. The axle is going back under the jeep tonight and I'll start the break in process.

What is weird to me is that I followed the same process (set-up race and new race) on the rear axle and everything worked like it should. I don't know what it is about this axle and its stack-up but something was obviously different. I also thought I checked my rotating torque on the axle before I buttoned it up and drove it, but now, I'm second guessing myself...It wouldn't be the first time I did something bone-headed like that, and I'm sure it won't be the last.

Also, I figured out the issue with the first set-up and why I roasted the pinion bearing...there is something about this housing and inner bearing race combination that sets up much differently than my set-up bearing. I found it again last night when I was doing final assembly and my rotating torque went high (like 50 in-lbs). I reset my preload shims and got it back down to 20 in-lbs. The axle is going back under the jeep tonight and I'll start the break in process.

What is weird to me is that I followed the same process (set-up race and new race) on the rear axle and everything worked like it should. I don't know what it is about this axle and its stack-up but something was obviously different. I also thought I checked my rotating torque on the axle before I buttoned it up and drove it, but now, I'm second guessing myself...It wouldn't be the first time I did something bone-headed like that, and I'm sure it won't be the last.