I have a little vibration around 40-50 mph and working to iron it out on a nice day. I have a stock driveshaft with a 1.5" TC drop and 3.5" lift. I have double-adjustable rear upper control arms so I'm confident I can set the pinion angle correctly, I just want to ensure I'm measuring from the right spot.

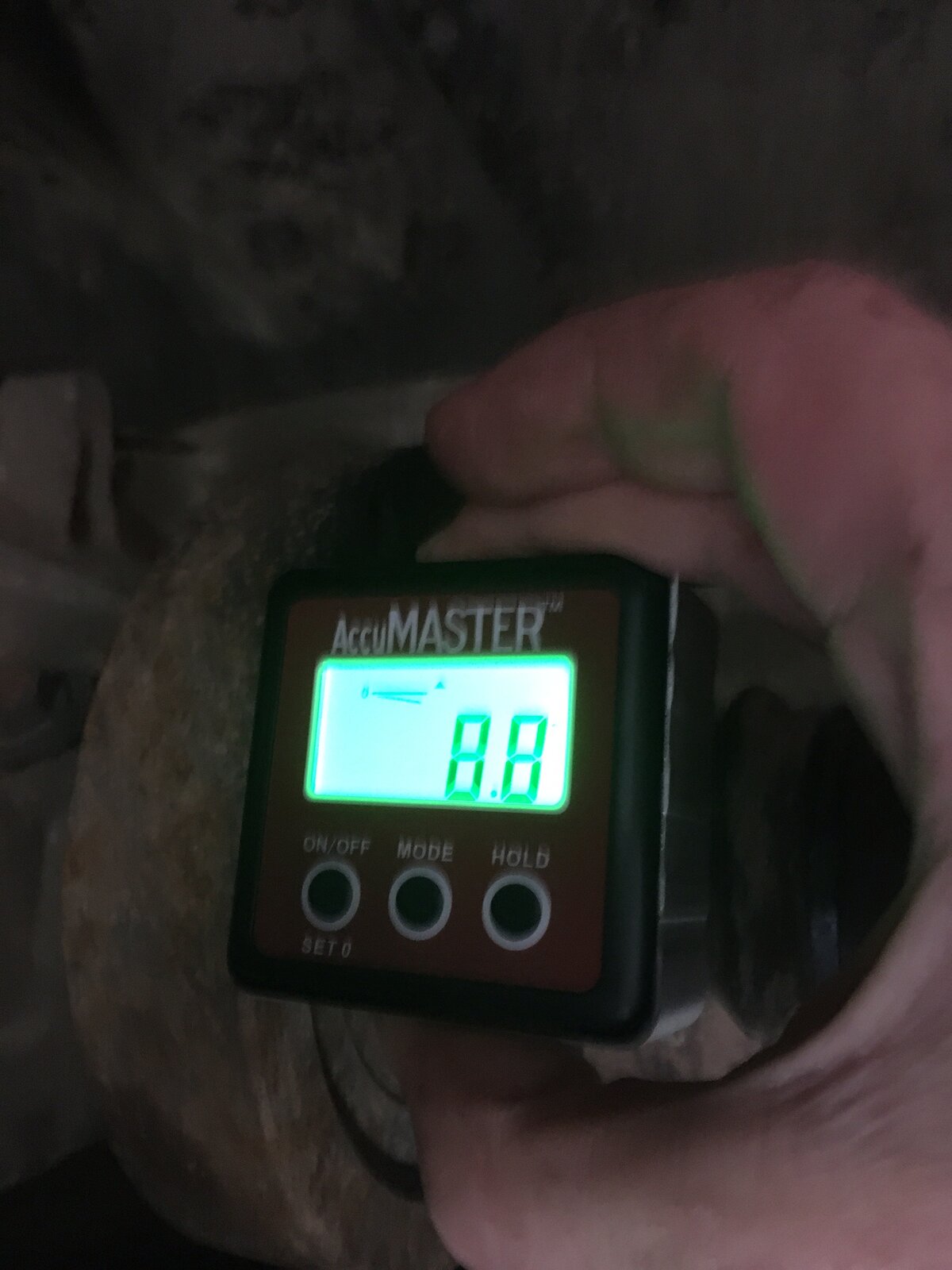

In the pictures below, I've looked at measuring from the top of the harmonic balancer and got 8.1*, then from the side and got 8.8*. (a) which one is correct to measure?

I figured the top was more accurate than the side and got the rears as close as I could. I measured them at the circles next to the back of the pumpkin. (I found this to be commonly referenced and feel confident about this. This is what I can adjust...by the TC case doesn't seem to adjust.

I've also included pictures of the entire setup in case I'm totally wrong.

EDIT: Some of the pictures are sorta dark. For whichever is unclear, I'm going to reshoot for clarity.

In the pictures below, I've looked at measuring from the top of the harmonic balancer and got 8.1*, then from the side and got 8.8*. (a) which one is correct to measure?

I figured the top was more accurate than the side and got the rears as close as I could. I measured them at the circles next to the back of the pumpkin. (I found this to be commonly referenced and feel confident about this. This is what I can adjust...by the TC case doesn't seem to adjust.

I've also included pictures of the entire setup in case I'm totally wrong.

EDIT: Some of the pictures are sorta dark. For whichever is unclear, I'm going to reshoot for clarity.