I am wanting to repaint my hood and I thought it would be easier doing it with the hood removed. My only concern is snapping the Torx bolts. They look to be in good shape but almost everything else I have ever unbolted seems to break them. It's probably a dumb question because they are all different being from different areas. I guess I am wanting to know how many have tried and regretted it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Removing hood

- Thread starter old jeep new to me

- Start date

Ct_tj

TJ Enthusiast

You're more likely to round out the torx than break them in my experience. Thats not just Jeep specific, I work on everything. Use a little bit of heat and just take it easy. Don't force anything because a rounded out torx could be more of a pain than just a broken bolt

Oklahomacheapjeep

Member

Get a little heat into them, get a GOOD torx bit and pound it in with a hammer. The heat and shock will help loosen corrosion. Then work the screw out. Start by tightening, then loosen until it stops. Tighten again, and loosen. You'll be able to feel it when the threads are free. After you do a couple, you'll develop a feel for how much pressure you can put on them. I used this method to remove 42 #10 screws with torx heads from my motorhome. They are steel and were in Aluminum for 42 years. I broke 6 out of 42.

I replace those stupid torx bolts with P3 or P4 phillips. Much easier to work with.

I replace those stupid torx bolts with P3 or P4 phillips. Much easier to work with.

Remove cowl, remove the screws at the other end of the hinge paying close attention to the shim stacks. That way you don't fuck up your nice paint job with shitty screws and adjusting the hood. Do it the right way.

Well a good torx bit will out last a Phillips, just have to have the correct tools.Get a little heat into them, get a GOOD torx bit and pound it in with a hammer. The heat and shock will help loosen corrosion. Then work the screw out. Start by tightening, then loosen until it stops. Tighten again, and loosen. You'll be able to feel it when the threads are free. After you do a couple, you'll develop a feel for how much pressure you can put on them. I used this method to remove 42 #10 screws with torx heads from my motorhome. They are steel and were in Aluminum for 42 years. I broke 6 out of 42.

I replace those stupid torx bolts with P3 or P4 phillips. Much easier to work with.

The bit may, the fasteners won't. For the shank size, a #4 Phillips drive is far superior.Well a good torx bit will out last a Phillips, just have to have the correct tools.

Yes I agree, those Torx bolts are stupid. Thanks for the help.Get a little heat into them, get a GOOD torx bit and pound it in with a hammer. The heat and shock will help loosen corrosion. Then work the screw out. Start by tightening, then loosen until it stops. Tighten again, and loosen. You'll be able to feel it when the threads are free. After you do a couple, you'll develop a feel for how much pressure you can put on them. I used this method to remove 42 #10 screws with torx heads from my motorhome. They are steel and were in Aluminum for 42 years. I broke 6 out of 42.

I replace those stupid torx bolts with P3 or P4 phillips. Much easier to work with.

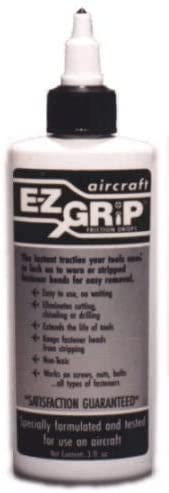

EZ-Grip. Get some! It does wonders for getting a great bite on any fastener & helps to keep them from rounding out

https://www.amazon.com/dp/B00BFEJY5W/?tag=wranglerorg-20

https://www.amazon.com/dp/B00BFEJY5W/?tag=wranglerorg-20