When working with the hood up I'm not a fan of the under-hood light being on the whole time; especially when I'm in the garage with good lighting. The easiest fix would be to to disconnect the light, but what if your connector is not working as it should?

My original connector was brittle with age and a pain to use. The red lock had broken and slipped out every time I'd move it back, and the part you press to unlock the connector from the light was cracked and wouldn't unlatch. I needed a micro screwdriver to lift the locking latch and disconnect the two. So I decided replaced the harness connector.

Here's what I used and how:

1. Disconnect the battery. I removed both neutral and positive terminals because I wanted no chance of my body or tools completing a circuit while doing any of these steps.

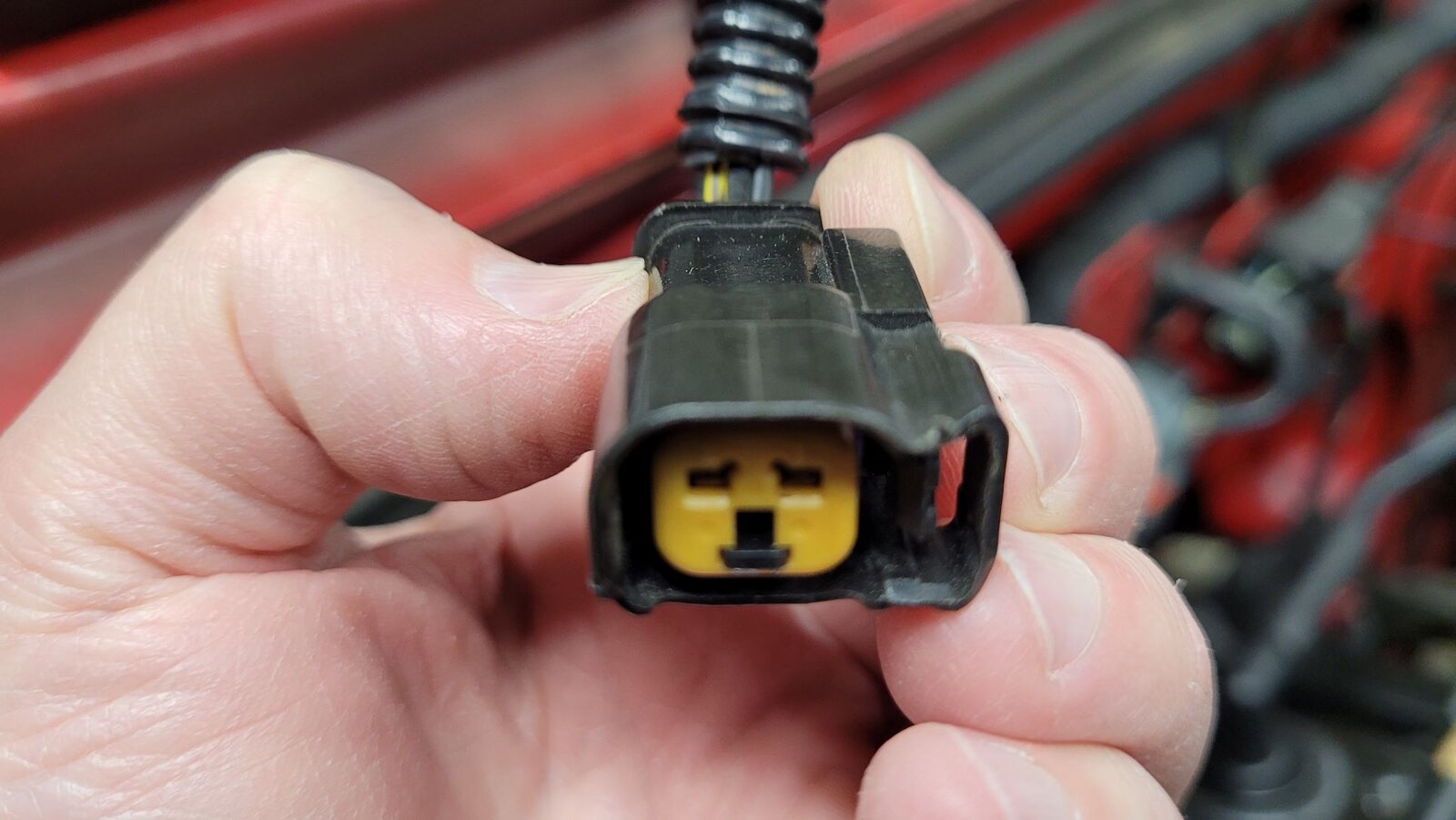

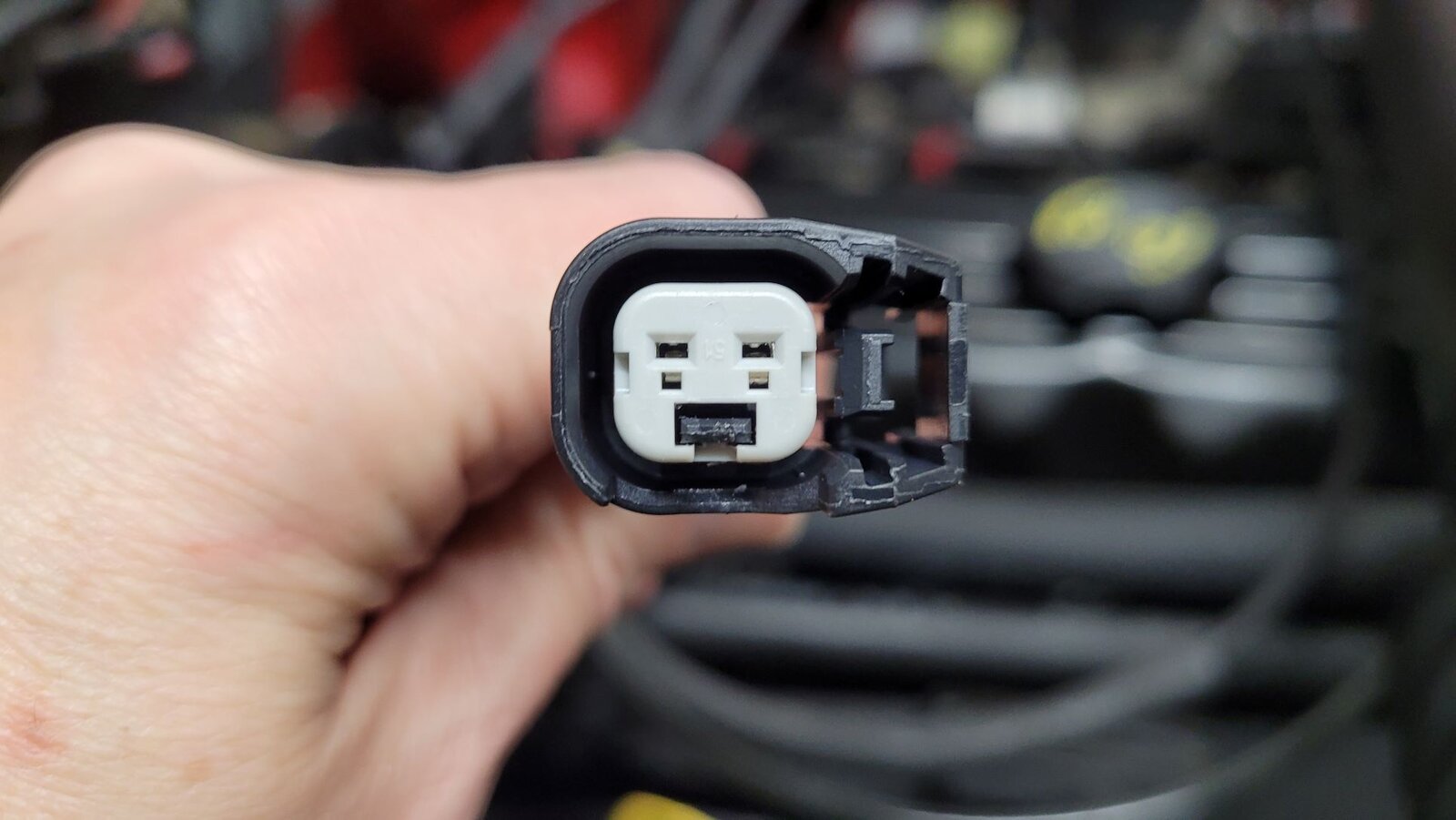

2. Remove stock connector from the light. Note the position of the colored wires at the rear of the connector, they will go into the new connector the same way. The yellow bit is a removable face plate. In the top two holes are the power terminals, the single hole at bottom is where you can insert a tool, I used a small screwdriver, to release the face plate. You may also pry the face plate off at the gap where it meets the sealing material on the underside.

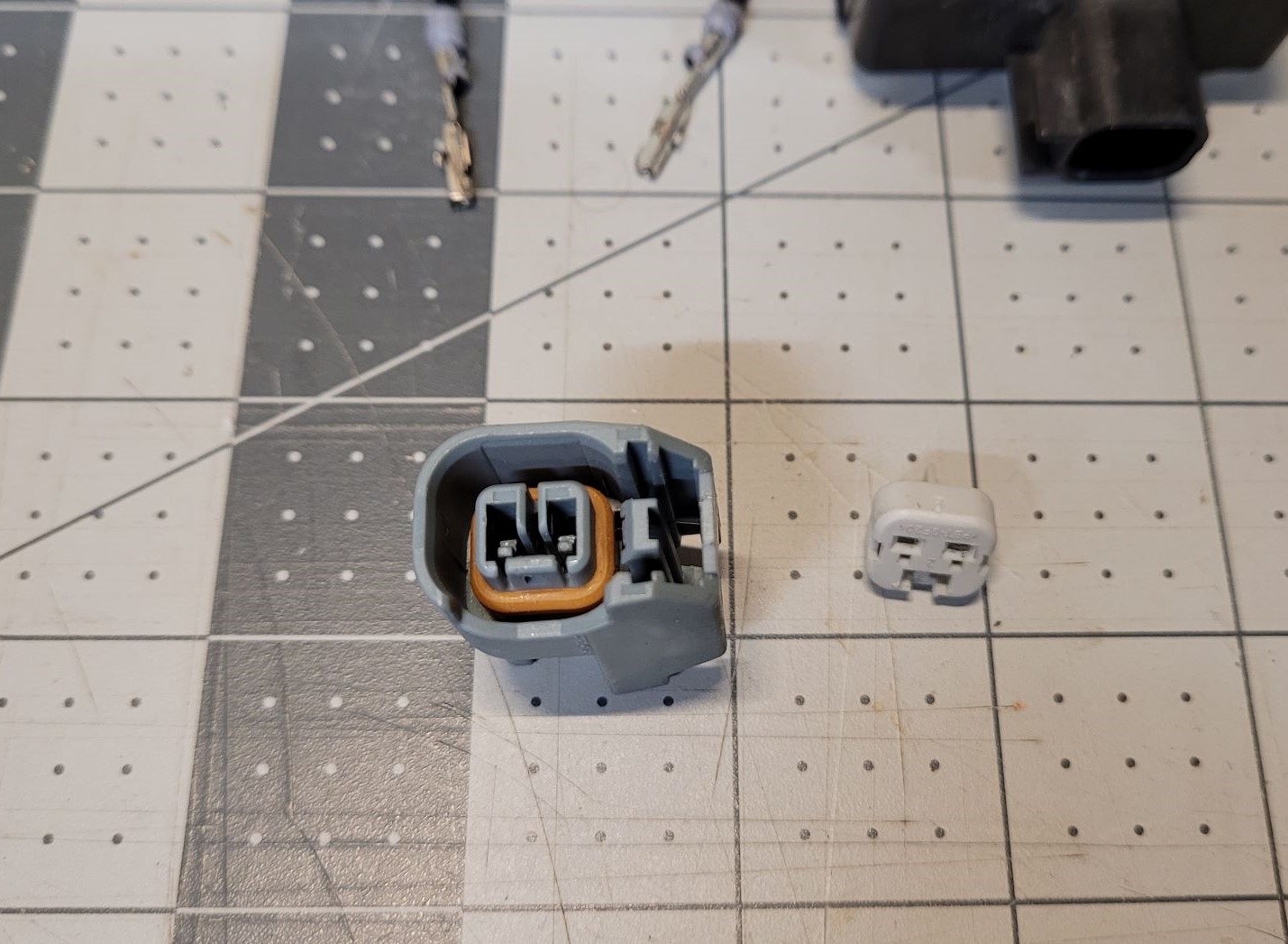

3. Remove the terminals from the connector. They are held in place by small tabs. Releasing each tab from the terminal allows you to pull the terminal from the rear of the connector. I used a small screwdriver for this. This is a similar connector on my bench with its face plate removed and you can see the two tabs in the center of the connector.

Exposed original terminals:

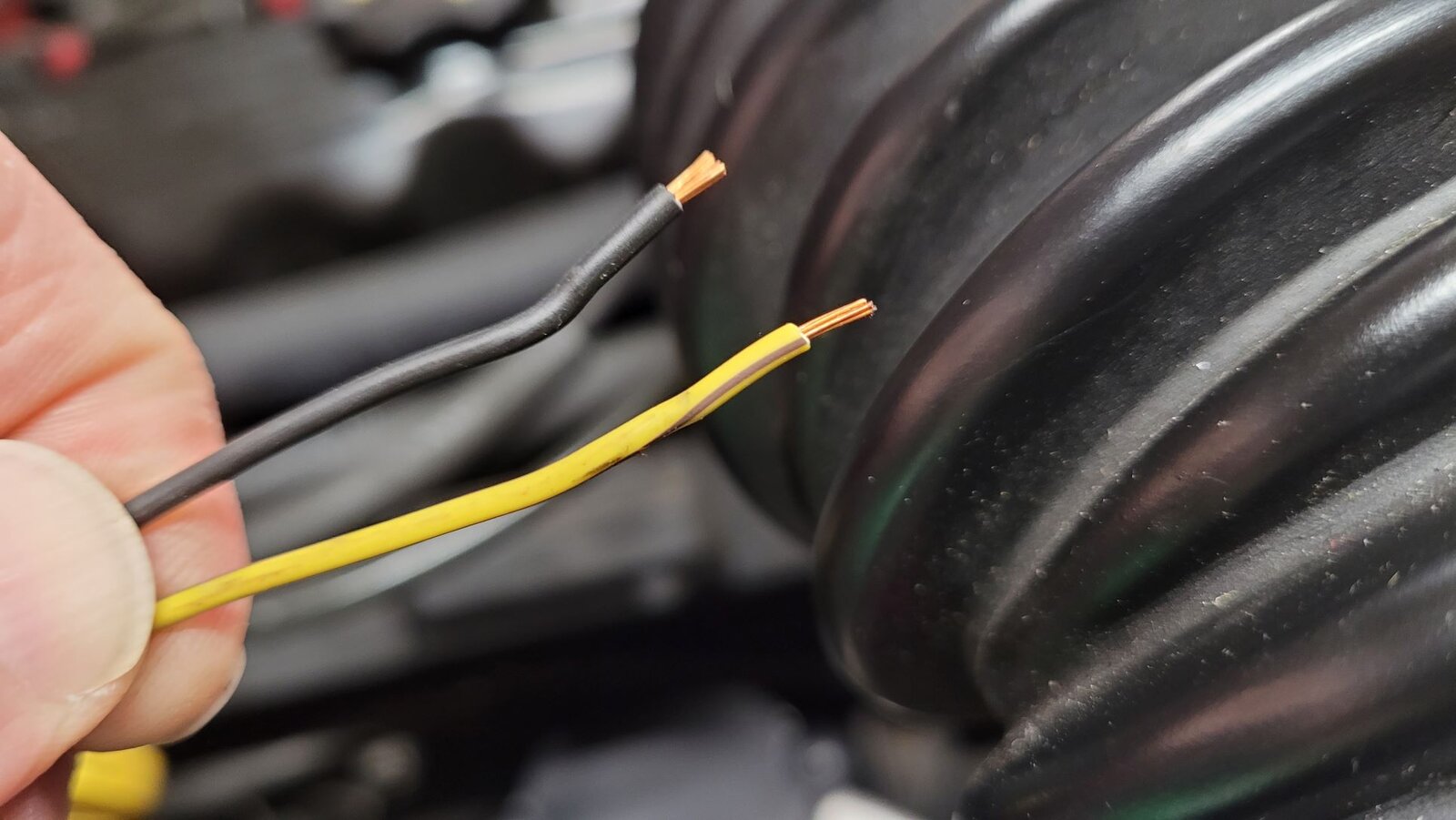

4. Cut off old terminals and strip wire. You want about 5mm (just about 3/16 of an inch) of exposed wire. It was easier for me to use millimeters, but you do you. This wire was 18 AWG.

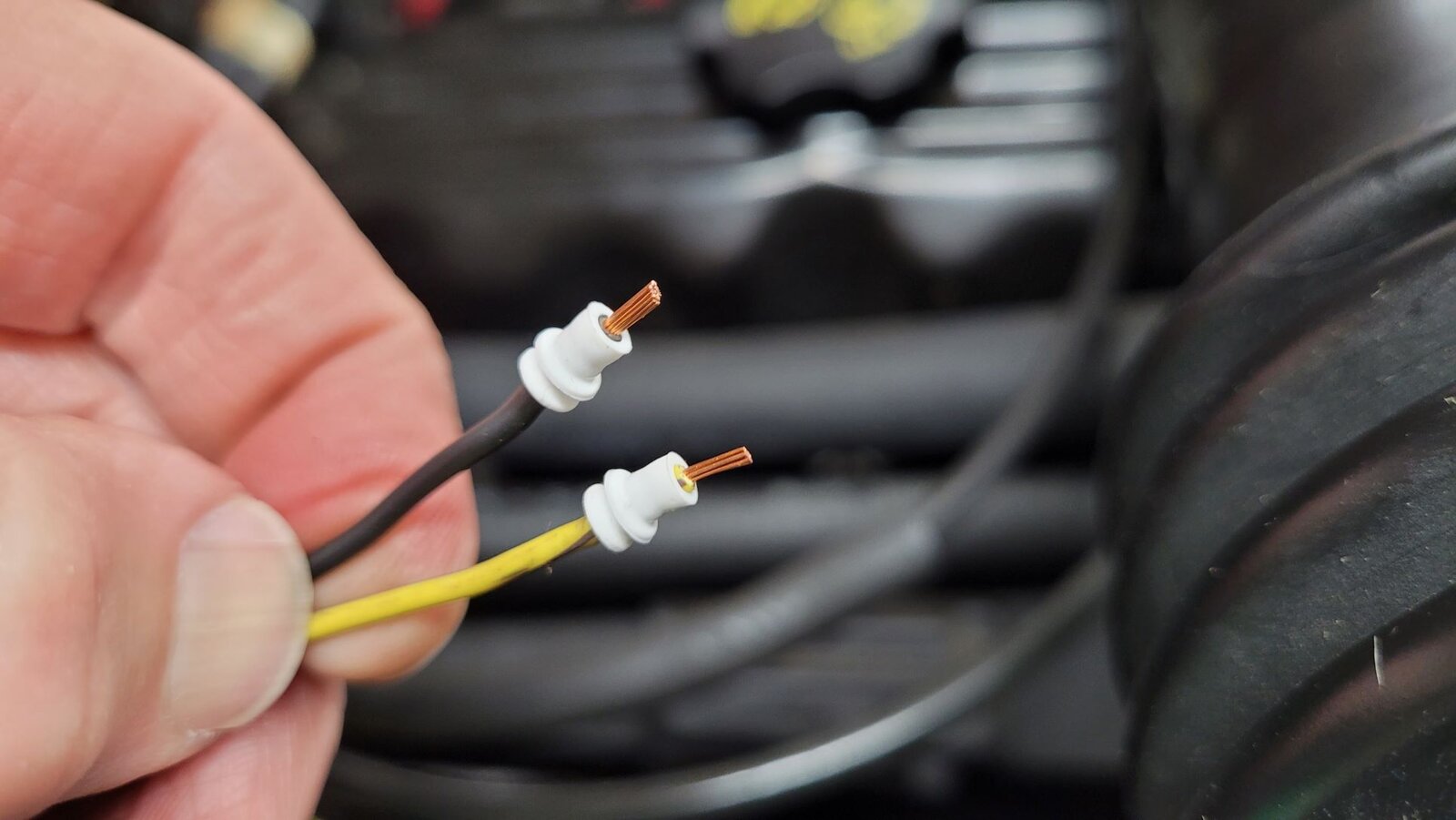

5. Put on new seals. This I considered an upgrade as the original connector didn't have a seal at the back, it was just open. It may not matter, but it's what I went with because the seals (and terminals) came with the connectors I ordered as a kit. You want the larger bit of the seal facing away from the wire's cut end and the small end flush with the wire's sheathing.

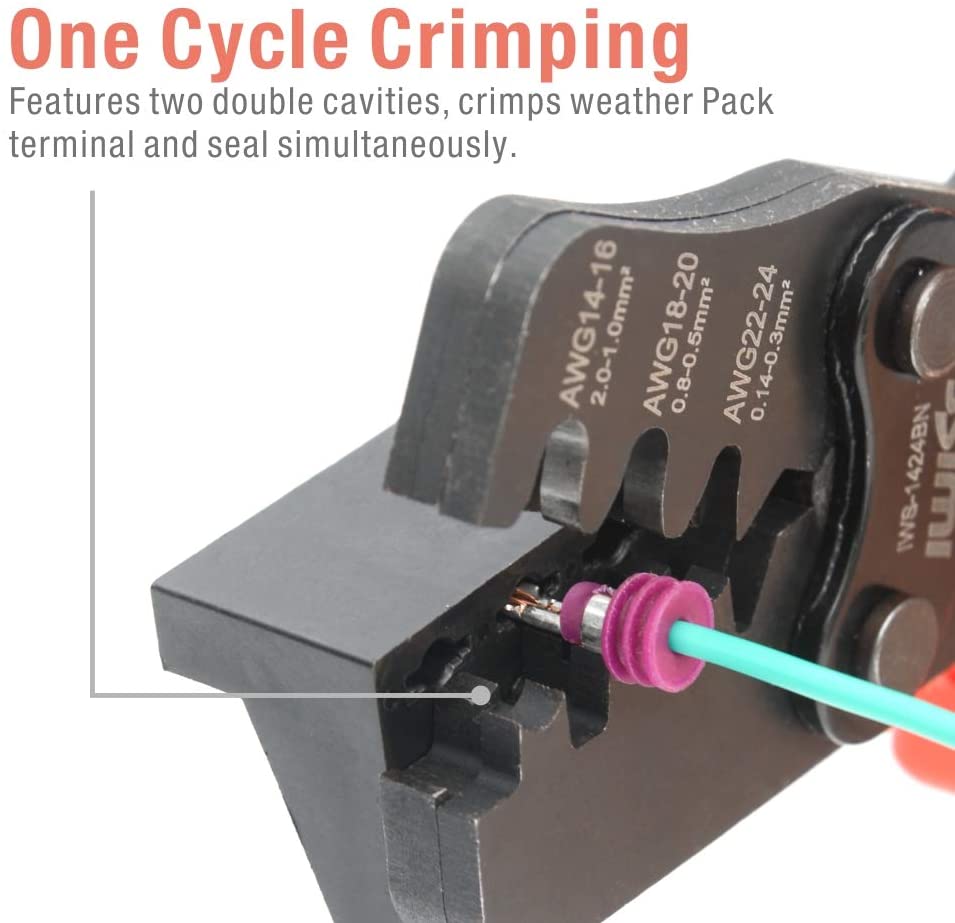

6. Crimp new terminals. I bought a crimper for this because it did both parts of the crimp, the wire part on the terminal and the sealing boot, at the same time. There are various types of these on Amazon but this (or a like model) is what I got.

New Terminals:

7. Insert terminals into new connector. Remember how the wires were originally and replace them exactly the same. There is an open recess on the underside of each terminal; the locking tabs in the connector go into that recess and this locks each terminal in place. Just pay attention to how they go in. Press each terminal trough the connector's rear until you hear them click. This can be easy, or it may be like pushing a rope up a wall. I had one go in fine and the other I needed to use a set of smooth jaw pliers to get the terminal the final 2mm to make the click.

8. Place new face place on connector. This is easy, just snap it on the front.

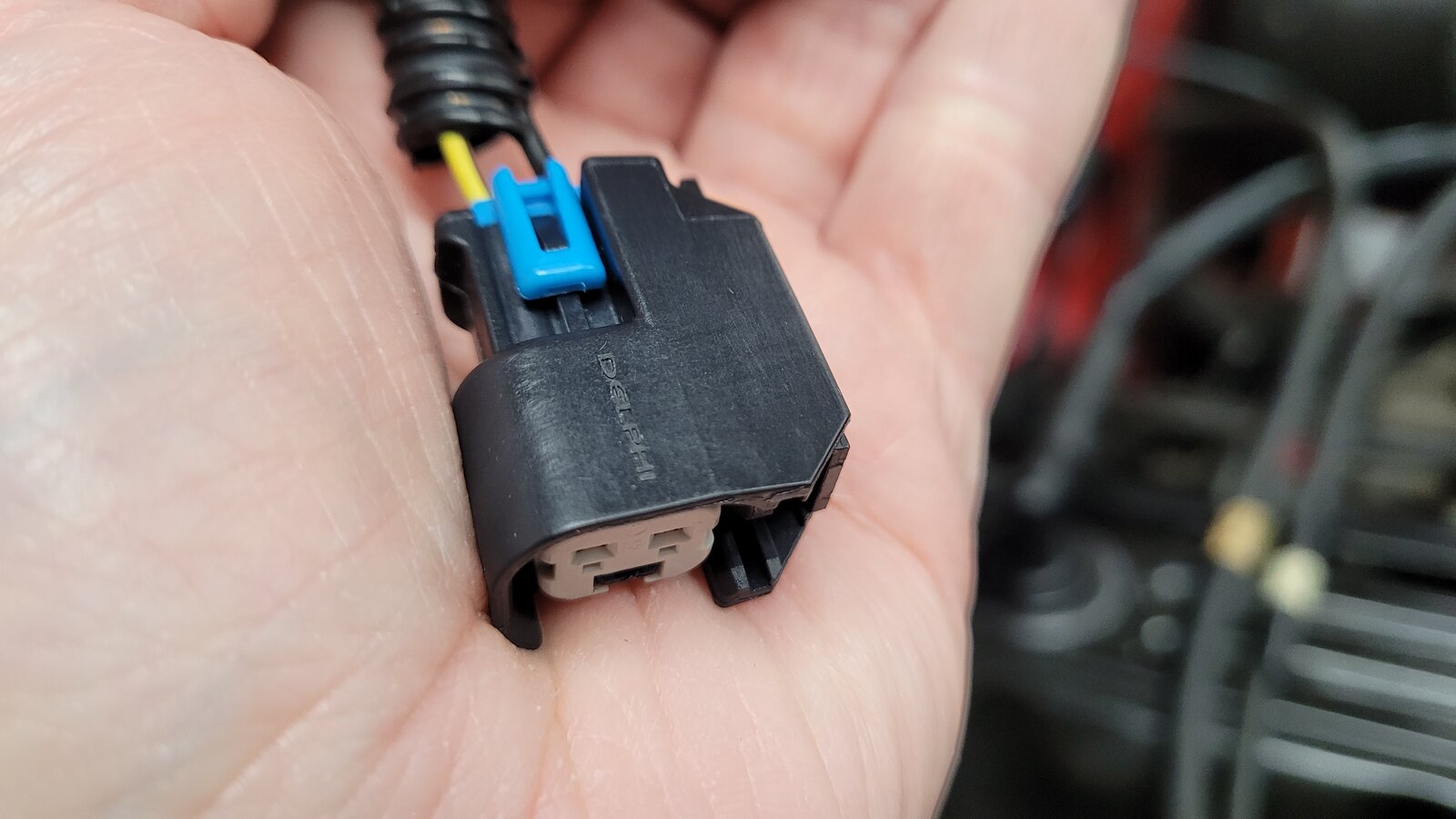

9. OPTIONAL: Place rear clip on connector. The blue clip keeps the wires apart. You could probably leave it off, but it came with the kit so I used it.

10. Reconnect the light. Once you have it connected, reconnect the battery and you should be good to go.

Materials:

Connectors:

I shopped Ballenger Motorsports (https://www.bmotorsports.com/) for their connector kit. I bought there because everything was together in one place.

The kit I used was the Black Delphi EV6/EV14 Injector Connector Kit (Part # CONN-76270)

Link: https://www.bmotorsports.com/shop/product_info.php/products_id/5490

An argument could be made for using their 2 Way ABS, Light, & Horn Connector Plug Kit (Part # CONN-76049)

https://www.bmotorsports.com/shop/product_info.php/products_id/4180

The main things to keep in mind with this is how many pins/terminals (or ways) the connector has, its overall size and the orientation of the locking mechanism in relation to the pins. I knew a fuel injector connector would work because it has the proper terminal/size/orientation combination. They were a little cheaper as well, but that wasn't a driving factor. They shipped quickly (I used USPS) and was very happy with the kit. Everything came in its own mini zip lock bag so nothing was lost in the box.

Crimpers:

As mentioned, I used Amazon. I searched using the terms Delphi, Weather Pack, and Metri-pack. The key here being where the wire goes requires a tighter and different crimp than what the seals do. Most of the pliers I found have two different sections to do each step. I thought the one step approach would be better, but I still dressed up each crimp on the seal, so that was a wash.

The crimpers I got also came with a block that attachs on the rear face, supposedly to hold the terminals and index everything properly. Only I couldn't get the square terminal ends into the block deep enough, so I took it off and still got everything lined up just fine. Actually, I found it easier to do this way because I could see how the wire was in the terminal as I started crimping and readjust to keep it in the right spot, if necessary.

This is a closeup of similar crimpers in use.

I thought it nice Ballenger sends 3 terminals and boots per connector just in case you mess one up. If this is your first time doing this, or using new crimpers, I highly suggest you get a few extra terminals and practice with them on some scrap wire. (It's not a difficult task, but you want to get it right when it counts.) Ballenger lists each component separately, so adding a few on an order is easy.

All of this work took probably less than 30 minutes. The hardest part was getting my mind right to cut the harness. I did all this in preparation of substituting the stock light with a reel light, and wanting to use the existing harness for power. If all you are looking to do is replace a busted connector on your stock light, I hope this helps you.

Thanks for reading!

My original connector was brittle with age and a pain to use. The red lock had broken and slipped out every time I'd move it back, and the part you press to unlock the connector from the light was cracked and wouldn't unlatch. I needed a micro screwdriver to lift the locking latch and disconnect the two. So I decided replaced the harness connector.

Here's what I used and how:

1. Disconnect the battery. I removed both neutral and positive terminals because I wanted no chance of my body or tools completing a circuit while doing any of these steps.

2. Remove stock connector from the light. Note the position of the colored wires at the rear of the connector, they will go into the new connector the same way. The yellow bit is a removable face plate. In the top two holes are the power terminals, the single hole at bottom is where you can insert a tool, I used a small screwdriver, to release the face plate. You may also pry the face plate off at the gap where it meets the sealing material on the underside.

3. Remove the terminals from the connector. They are held in place by small tabs. Releasing each tab from the terminal allows you to pull the terminal from the rear of the connector. I used a small screwdriver for this. This is a similar connector on my bench with its face plate removed and you can see the two tabs in the center of the connector.

Exposed original terminals:

4. Cut off old terminals and strip wire. You want about 5mm (just about 3/16 of an inch) of exposed wire. It was easier for me to use millimeters, but you do you. This wire was 18 AWG.

5. Put on new seals. This I considered an upgrade as the original connector didn't have a seal at the back, it was just open. It may not matter, but it's what I went with because the seals (and terminals) came with the connectors I ordered as a kit. You want the larger bit of the seal facing away from the wire's cut end and the small end flush with the wire's sheathing.

6. Crimp new terminals. I bought a crimper for this because it did both parts of the crimp, the wire part on the terminal and the sealing boot, at the same time. There are various types of these on Amazon but this (or a like model) is what I got.

New Terminals:

7. Insert terminals into new connector. Remember how the wires were originally and replace them exactly the same. There is an open recess on the underside of each terminal; the locking tabs in the connector go into that recess and this locks each terminal in place. Just pay attention to how they go in. Press each terminal trough the connector's rear until you hear them click. This can be easy, or it may be like pushing a rope up a wall. I had one go in fine and the other I needed to use a set of smooth jaw pliers to get the terminal the final 2mm to make the click.

8. Place new face place on connector. This is easy, just snap it on the front.

9. OPTIONAL: Place rear clip on connector. The blue clip keeps the wires apart. You could probably leave it off, but it came with the kit so I used it.

10. Reconnect the light. Once you have it connected, reconnect the battery and you should be good to go.

Materials:

Connectors:

I shopped Ballenger Motorsports (https://www.bmotorsports.com/) for their connector kit. I bought there because everything was together in one place.

The kit I used was the Black Delphi EV6/EV14 Injector Connector Kit (Part # CONN-76270)

Link: https://www.bmotorsports.com/shop/product_info.php/products_id/5490

An argument could be made for using their 2 Way ABS, Light, & Horn Connector Plug Kit (Part # CONN-76049)

https://www.bmotorsports.com/shop/product_info.php/products_id/4180

The main things to keep in mind with this is how many pins/terminals (or ways) the connector has, its overall size and the orientation of the locking mechanism in relation to the pins. I knew a fuel injector connector would work because it has the proper terminal/size/orientation combination. They were a little cheaper as well, but that wasn't a driving factor. They shipped quickly (I used USPS) and was very happy with the kit. Everything came in its own mini zip lock bag so nothing was lost in the box.

Crimpers:

As mentioned, I used Amazon. I searched using the terms Delphi, Weather Pack, and Metri-pack. The key here being where the wire goes requires a tighter and different crimp than what the seals do. Most of the pliers I found have two different sections to do each step. I thought the one step approach would be better, but I still dressed up each crimp on the seal, so that was a wash.

The crimpers I got also came with a block that attachs on the rear face, supposedly to hold the terminals and index everything properly. Only I couldn't get the square terminal ends into the block deep enough, so I took it off and still got everything lined up just fine. Actually, I found it easier to do this way because I could see how the wire was in the terminal as I started crimping and readjust to keep it in the right spot, if necessary.

This is a closeup of similar crimpers in use.

I thought it nice Ballenger sends 3 terminals and boots per connector just in case you mess one up. If this is your first time doing this, or using new crimpers, I highly suggest you get a few extra terminals and practice with them on some scrap wire. (It's not a difficult task, but you want to get it right when it counts.) Ballenger lists each component separately, so adding a few on an order is easy.

All of this work took probably less than 30 minutes. The hardest part was getting my mind right to cut the harness. I did all this in preparation of substituting the stock light with a reel light, and wanting to use the existing harness for power. If all you are looking to do is replace a busted connector on your stock light, I hope this helps you.

Thanks for reading!

Last edited: