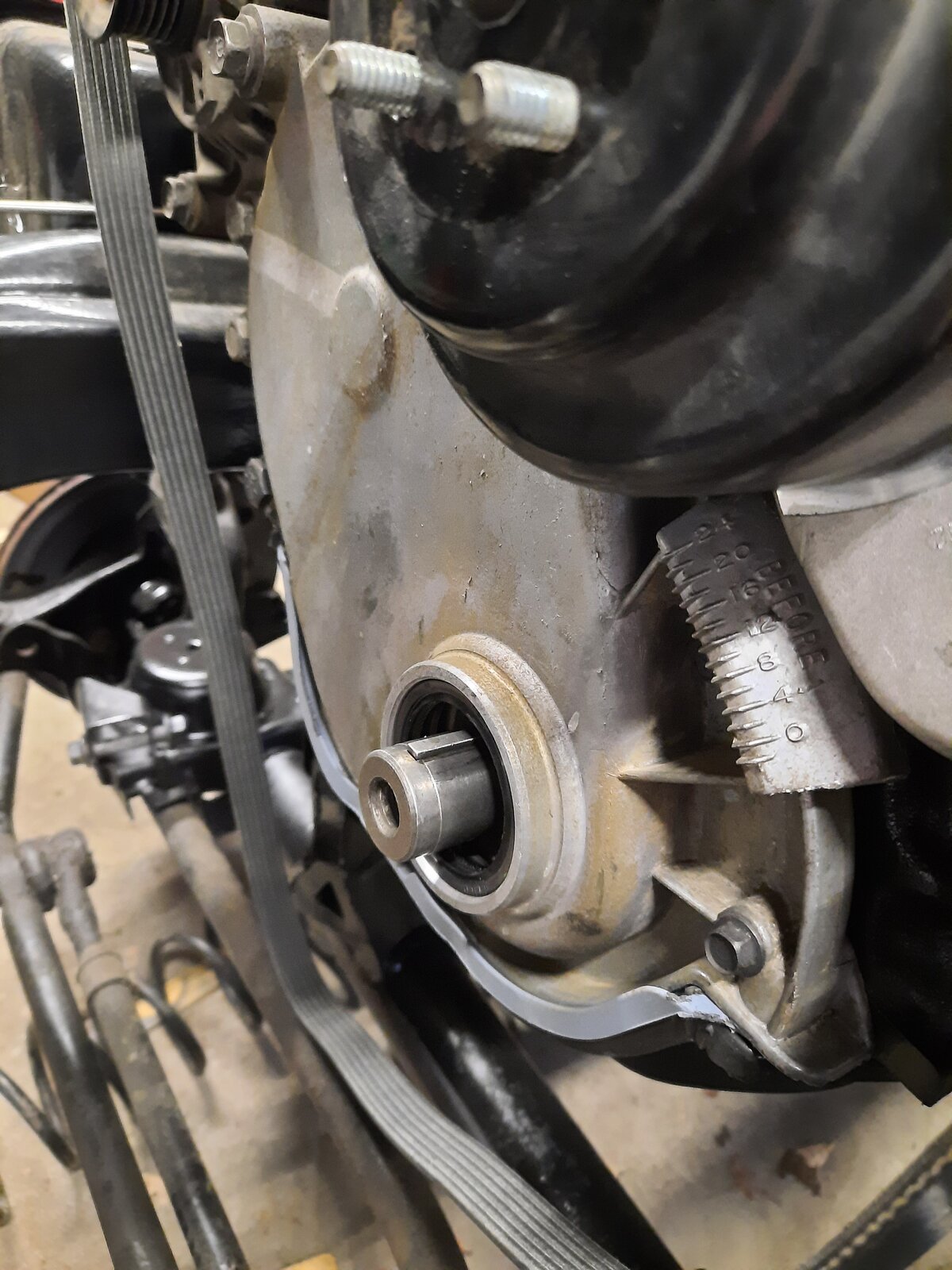

Any idea how to shorten the snout of my 232 crank by about 3/8" in vehicle? I imagine the machinists do it on a lathe but I'm not going to tear the motor apart just for this.

Edit: thinking about this more I guess the end does not need to be perfectly squared to the crank since there is no loading or alignment based on the end face of the crank.

Edit: thinking about this more I guess the end does not need to be perfectly squared to the crank since there is no loading or alignment based on the end face of the crank.

Last edited: