You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Synthetic winch line without any thimble at all

- Thread starter srimes

- Start date

There's a few threads with that idea in there, but my question is why?

To sum up what little I know there's a number of reasons not to:

1. Abrasion protection for the most at risk part of the line

2. The strength is higher when the loop is more open (e.g. around a thimble)

3. Safety when spooling the line back up

To sum up what little I know there's a number of reasons not to:

1. Abrasion protection for the most at risk part of the line

2. The strength is higher when the loop is more open (e.g. around a thimble)

3. Safety when spooling the line back up

Like this?Not talking about safety thimble vs hook (people use a thimble with a hook), I'm thinking of running just a loop with no thimble. Anyone here have experience with that?

If you understand why a thimble is used and needed, then you know the answer.Not talking about safety thimble vs hook (people use a thimble with a hook), I'm thinking of running just a loop with no thimble. Anyone here have experience with that?

Looks like a good way to lose a finger.Yes! Without the vinyl coating

If you understand why a thimble is used and needed, then you know the answer.

It's needed for abrasion and possible diameter. When connecting to a soft shackle or smooth hard shackle neither should be a problem.

Looks like a good way to lose a finger.

yeah I'm not talking about their fairlead. I'll leave it on a shackle or tow hook.

2. The strength is higher when the loop is more open (e.g. around a thimble)

*Radius.

If I'm not mistaken, @Apparition was referring to the safety aspect that the thimble provides?yeah I'm not talking about their fairlead. I'll leave it on a shackle or tow hook.

Yep can't suck the line (with your hand) through whatever fairlead you are running.If I'm not mistaken, @Apparition was referring to the safety aspect that the thimble provides?

And last time I left a soft shackle on my front bumper I destroyed it on a rock. There's a reason the TRE setup was designed how it is.

If you do some research, the line companies have minimum radius requirements to keep the line at its rated breaking strength. It is usually given as X times the line diameter. You can't maintain that with either a soft shackle or steel shackle. Again, if you understand why a thimble is used, you already know the answer.It's needed for abrasion and possible diameter. When connecting to a soft shackle or smooth hard shackle neither should be a problem.

If you do some research, the line companies have minimum radius requirements to keep the line at its rated breaking strength. It is usually given as X times the line diameter. You can't maintain that with either a soft shackle or steel shackle. Again, if you understand why a thimble is used, you already know the answer.

I've done some research, mainly on the sailing/marine side. For a terminal loop it's well established that D/d ration of 1:1 is sufficient. That bend radius cuts the rope strength in half, and with the 2 legs of a loop you get full single-line strength. My soft and steel shackles are bigger that the 3/8 winch line so that isn't the problem.

I'm asking here to learn what experience people have and what to watch out for. So far it seems the main concern is that the end can pass through the fairlead.

Why is the drum diameter about 3"?I've done some research, mainly on the sailing/marine side. For a terminal loop it's well established that D/d ration of 1:1 is sufficient. That bend radius cuts the rope strength in half, and with the 2 legs of a loop you get full single-line strength. My soft and steel shackles are bigger that the 3/8 winch line so that isn't the problem.

I'm asking here to learn what experience people have and what to watch out for. So far it seems the main concern is that the end can pass through the fairlead.

Why is the drum diameter about 3"?

The drum isn't a terminal loop, it's more like a sheave. Samson recommends 8x rope diameter minimum for sheaves.

I guess I'll be the guinea pig here. I'll let yall know how it goes. Unless it kills me, in which case you won't hear back.

Be safe, it's synthetic and it breaks. Don't ignore the first two points @rasband made just because you did the math. That "might" be where you have problems which manifest themselves as broken loops. If you know how to make another loop and work safe it'll be a worthwhile experiment.

Yes you can run a "Soft Eye" but it is not ideal and you will need to add something to increase abrasion resistance unless you want to become a master of splicing. I would do this for an extension line since it normally sees less use but not for my main line.I've done some research, mainly on the sailing/marine side. For a terminal loop it's well established that D/d ration of 1:1 is sufficient. That bend radius cuts the rope strength in half, and with the 2 legs of a loop you get full single-line strength. My soft and steel shackles are bigger that the 3/8 winch line so that isn't the problem.

I'm asking here to learn what experience people have and what to watch out for. So far it seems the main concern is that the end can pass through the fairlead.

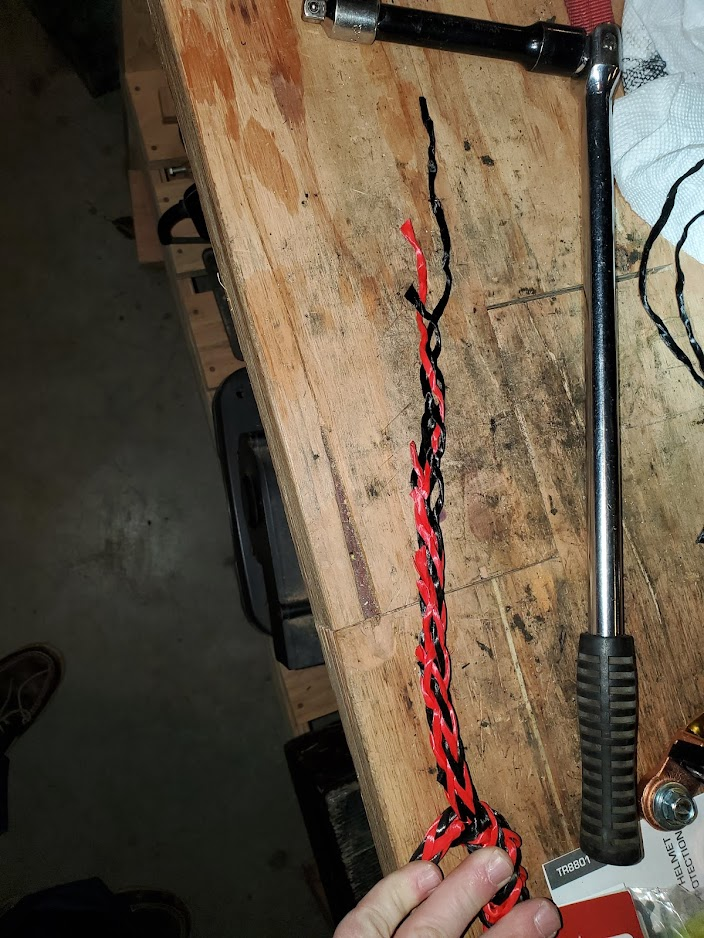

Took of the thimble last night. Chaff sleeve had a lock stitch to hold it in place, which is stupid as you need to be able to move the sleeve where needed and to inspect the rope. I removed the stitch.

The factory didn't taper the splice, leaving a sharp transition as seen below. This the the most likely point of breakage.

I measured 27" for bury (3/8x72) + the loop size I wanted and ran the tail through and out. To taper I pulled individual strands out and trimmed to get a nice gradual taper.

My soft shackles came with extra chaff sleeves so I used one of those for the loop. Bigger than needed but better to big than too small. It's very important to be able to pull the sleeve back and inspect the rope for damage.

The factory didn't taper the splice, leaving a sharp transition as seen below. This the the most likely point of breakage.

I measured 27" for bury (3/8x72) + the loop size I wanted and ran the tail through and out. To taper I pulled individual strands out and trimmed to get a nice gradual taper.

My soft shackles came with extra chaff sleeves so I used one of those for the loop. Bigger than needed but better to big than too small. It's very important to be able to pull the sleeve back and inspect the rope for damage.

My first impression is it is safer by a ratio of the weight of the abrasion cover to the weight of a thimble (any type). The minimum diameter of your winch line will be whatever you put it around (and it's minimum dia. at load).

I am hoping Mrblaine will kick with the answer of why (for us dummies that do knot know).

I am hoping Mrblaine will kick with the answer of why (for us dummies that do knot know).

A clever rope pun!(for us dummies that do knot know).