Quick question for the brain trust:

When trimming the tub with armor, is it best to trim the tub first, then trim the armor - OR - trim both at once? I've trimmed many a fender before but I have never trimmed a fender with armor, so I figured it was worth an ask...

I seem to be clear in the front (for now) but I'm hitting hard in the rear (I've got another 1.5-2" of uptravel to go here):

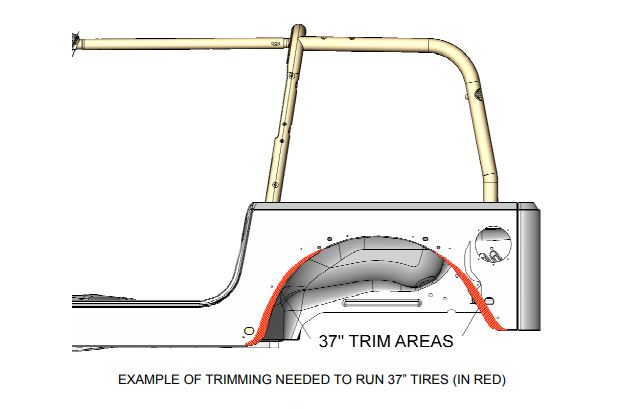

I found some old AEV Hi-Line instructions and they have a good guide-sheet. I may trim the front as suggested while I have the tools out and the wheels off:

When trimming the tub with armor, is it best to trim the tub first, then trim the armor - OR - trim both at once? I've trimmed many a fender before but I have never trimmed a fender with armor, so I figured it was worth an ask...

I seem to be clear in the front (for now) but I'm hitting hard in the rear (I've got another 1.5-2" of uptravel to go here):

I found some old AEV Hi-Line instructions and they have a good guide-sheet. I may trim the front as suggested while I have the tools out and the wheels off: