Victory. Rear shocks/springs installed = lift completed. While we were down there we installed the new fuel pump. Goes to shop Monday for wheels, tires, alignment and bonus round of new rear stud since the fuckers at the shop torqued the lugs so tight we snapped a stud.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to your TJ today?

- Thread starter LJRubiconGuy

- Start date

Victory. Rear shocks/springs installed = lift completed. While we were down there we installed the new fuel pump. Goes to shop Monday for wheels, tires, alignment and bonus round of new rear stud since the fuckers at the shop torqued the lugs so tight we snapped a stud.

View attachment 307272

View attachment 307273

View attachment 307274

View attachment 307275

View attachment 307276

View attachment 307277

View attachment 307278

Yoga Pants FTW !

Not a fan of the fastback top,tjs are already small enough.also since I put my shackles away in the bag,so much happier too.Love that look. IMHO get those shackles off the front bumper...one less thing rattling...two... shackles on bumpers tend to rust and about the time you need em you're cursing up a blue streak knee deep in mud or snow... hopefully with a couple big wrenches and a torch.

When I bought my Jeep the PO had two shackles on the front....took about an hour to get em off...they broke loose just a second before I was headed for the gas axe.

-Mac

Mine's nicer!

Everytime I see a smartphone, or even think about one; for some odd reason I think of pistols...Every time I use my smartphone I think about @Zorba.

You know its a proper install when you bleed for it!Victory. Rear shocks/springs installed = lift completed. While we were down there we installed the new fuel pump. Goes to shop Monday for wheels, tires, alignment and bonus round of new rear stud since the fuckers at the shop torqued the lugs so tight we snapped a stud.

View attachment 307272

View attachment 307273

View attachment 307274

View attachment 307275

View attachment 307276

View attachment 307277

View attachment 307278

@Zorba The eye shadow and dot though... LMAO

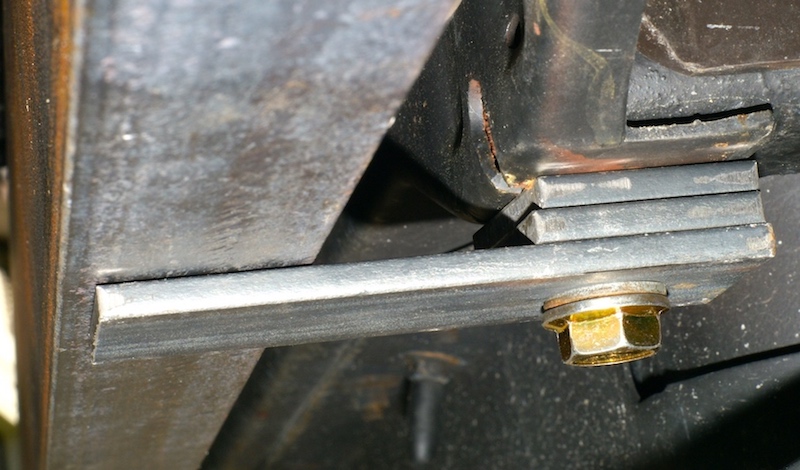

Fabbed up the bottom bumper-to-frame straps.

Completed straps with square washers AKA spacers...

I drilled most of the holes on my little Harbor Bomber drill press, but the half inchers in the square washers just weren't going through. Time to bring out "old Grandad", my late father's drill which I think dates from the 1930s. NOTHING stops that drill! 1/2", single speed, non-reversing, low speed and very high torque drill!

Trial fitment. Still needs to be bolted to the bumper proper with the temp 1/4" bolts - then off to the welding shop it goes! A better way to do this would have been to heat and bend the strap into a semi-"S" shape and omit the 1/2" of spacers - BUT my little propane torch wasn't doing it so it was time for plan "B".

Completed straps with square washers AKA spacers...

I drilled most of the holes on my little Harbor Bomber drill press, but the half inchers in the square washers just weren't going through. Time to bring out "old Grandad", my late father's drill which I think dates from the 1930s. NOTHING stops that drill! 1/2", single speed, non-reversing, low speed and very high torque drill!

Trial fitment. Still needs to be bolted to the bumper proper with the temp 1/4" bolts - then off to the welding shop it goes! A better way to do this would have been to heat and bend the strap into a semi-"S" shape and omit the 1/2" of spacers - BUT my little propane torch wasn't doing it so it was time for plan "B".

I have to look GORGEOUS for my HUNDREDS of ADORING fans!@Zorba The eye shadow and dot though... LMAO

My dad had an old rockwell drill like that. Damn near broke my wrist with it once.Fabbed up the bottom bumper-to-frame straps.

View attachment 307305

Completed straps with square washers AKA spacers...

View attachment 307306

I drilled most of the holes on my little Harbor Bomber drill press, but the half inchers in the square washers just weren't going through. Time to bring out "old Grandad", my late father's drill which I think dates from the 1930s. NOTHING stops that drill! 1/2", single speed, non-reversing, low speed and very high torque drill!

View attachment 307307

Trial fitment. Still needs to be bolted to the bumper proper with the temp 1/4" bolts - then off to the welding shop it goes! A better way to do this would have been to heat and bend the strap into a semi-"S" shape and omit the 1/2" of spacers - BUT my little propane torch wasn't doing it so it was time for plan "B".

This one is a "Thor", and when you pull the trigger, something is going to rotate. It just might be you!My dad had an old rockwell drill like that. Damn near broke my wrist with it once.

Good thing you can danceThis one is a "Thor", and when you pull the trigger, something is going to rotate. It just might be you!

I think it turned at 500rpm and used a two planetary gear drive. The only time it stopped turning anything was when it had my trigger finger pinched between the trigger and a rafter. Didn’t have a cheater bar on it, just the D handle. Took everything I had to turn against the torque and release the trigger. Ouch.This one is a "Thor", and when you pull the trigger, something is going to rotate. It just might be you!

Oh yea - there's nothing stopping one of those low speed drills. The Thor is 420 RPM, and about 8 amps running current. Goddess knows what the locked rotor current would be...I think it turned at 500rpm and used a two planetary gear drive. The only time it stopped turning anything was when it had my trigger finger pinched between the trigger and a rafter. Didn’t have a cheater bar on it, just the D handle. Took everything I had to turn against the torque and release the trigger. Ouch.

Fortunately, twirling and spinning are part of dancing!Good thing you can dance

Steel case and wires,we called those things(widow makers)Oh yea - there's nothing stopping one of those low speed drills. The Thor is 420 RPM, and about 8 amps running current. Goddess knows what the locked rotor current would be...

That's why its grounded - and its made of that new fangled Aluminum stuff...Steel case and wires,we called those(widow makers)

With that said, the ground was inoperative for the entire period of my childhood! My father was an electrician - why would he ground a metal drill?

Last edited:

Yep,my dad broke them off so they would fit in the (new fangled) outletsThat's why its grounded - and its made of that new fangled Aluminum stuff...

With that said, the ground was inoperative for the entire period of my childhood! My father was an electrician - why would he ground a metal drill?