My new (to me) 06 LJR w/80K miles on it. I just installed a Metalcloak 3.5 shortarm w/ adjustable links & Currectlink steering. Ball joints looked solid.

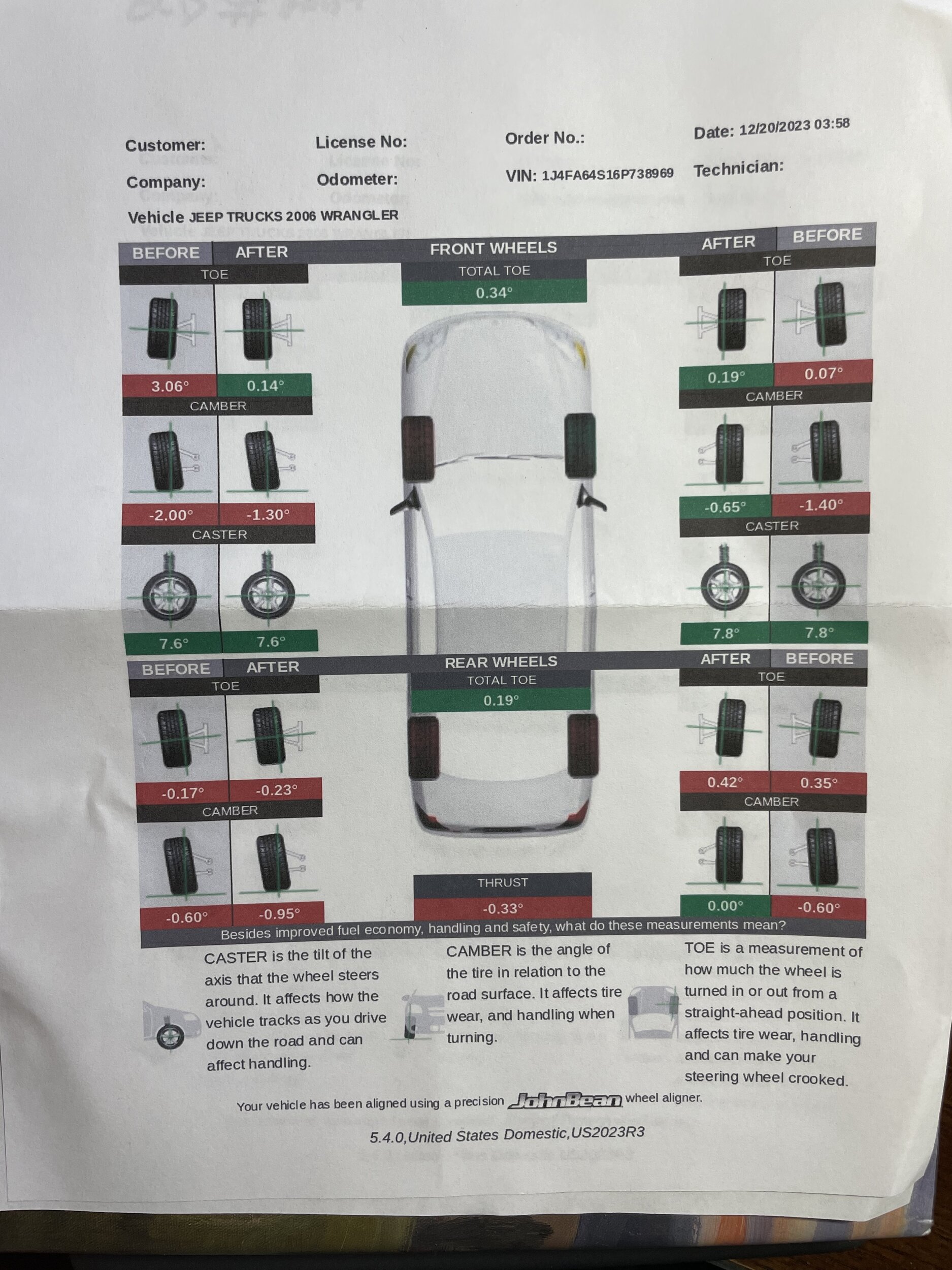

So, after alignment by experienced 4x4 shop, Jeep

pulling to right. Alignment guy said I need adjustable ball joint to correct camber. I contacted MC & Wil thought I could change caster to 5-6* and toe to 1/8”. He also said they never have to put adjustable ball joints in with these lifts.

i don’t mind changing out but thought I’d ask the group. Also, I can’t find a Spicer part # for those. What’s everyone use!

So, after alignment by experienced 4x4 shop, Jeep

pulling to right. Alignment guy said I need adjustable ball joint to correct camber. I contacted MC & Wil thought I could change caster to 5-6* and toe to 1/8”. He also said they never have to put adjustable ball joints in with these lifts.

i don’t mind changing out but thought I’d ask the group. Also, I can’t find a Spicer part # for those. What’s everyone use!