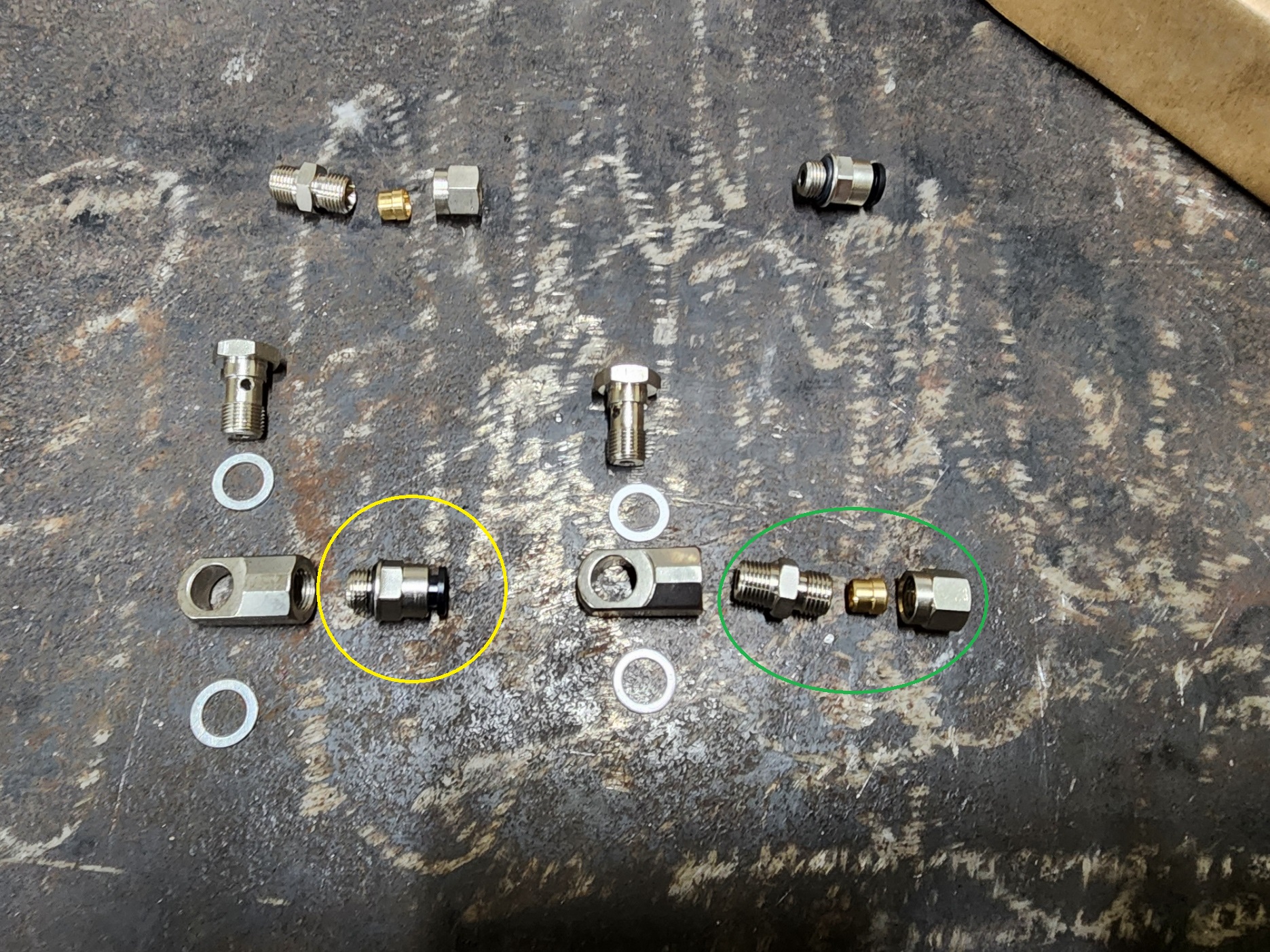

I need to run air lines from my ARB manifold to my new lockers. The solenoids come with the easy press in fittings below (yellow). The diff bulkhead fitting kits come with both the easy press in fittings and the ferule capture setup (green).

What are the pros and cons of going either way at the differential? Any experience out there to go with or stay away from one or the other? Is the 90* setup ok to use or better to go straight in from the top?

What are the pros and cons of going either way at the differential? Any experience out there to go with or stay away from one or the other? Is the 90* setup ok to use or better to go straight in from the top?