You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Baby Blue

- Thread starter Duredel

- Start date

It's the time of the year up here where you realize winter will be here very, very soon. The TJ has been on the back burner while I've been winterizing the house, stacking firewood, and getting through a busy fall at work. Despite that, I've been able to get a few little things done in the past month.

My girlfriend's brother has a '94 XJ with my old 33s- once I realized I wouldn't be wheeling much in the foreseeable future I passed them on to him. He wanted to replace his Dana 35 with a Chrysler 8.25, and I needed a HP Dana 30 out of an XJ.

We were able to find a '99 XJ for $600. It ran and drove, but the interior was a little messed up- apparently it had been a drug den for a while, then the seller had bought it with grand plans that fell through. It was also missing the title. Perfect for us!

While I was up in Barrow, he swapped over the front Dana 30 for me. The parts jeep has tons of stuff that will work for either the TJ, his XJ, or my XJ, both of which are '99s with a tan interior. Surprisingly, most of the plastic trim pieces are in a lot better shape than mine. I don't have room to store the whole jeep, but we'll strip what we can and toss it in the shed. We'll probably pull the whole drivetrain, seeing as we have 3 jeeps it could go into if something happens.

The old TJ axle had a track bar drop bracket welded on to the axle, so I installed an adjustable one. Other than getting the top and doors off, that's about all I've been able to do.

I've got a bunch of parts on the way, but Amazon has been really slow. Up here we're used to Prime taking 4 or 5 days, but they're saying some of my stuff is a month out. Anyone else experiencing that?

Looks like next weekend is the time for the !

!

My girlfriend's brother has a '94 XJ with my old 33s- once I realized I wouldn't be wheeling much in the foreseeable future I passed them on to him. He wanted to replace his Dana 35 with a Chrysler 8.25, and I needed a HP Dana 30 out of an XJ.

We were able to find a '99 XJ for $600. It ran and drove, but the interior was a little messed up- apparently it had been a drug den for a while, then the seller had bought it with grand plans that fell through. It was also missing the title. Perfect for us!

While I was up in Barrow, he swapped over the front Dana 30 for me. The parts jeep has tons of stuff that will work for either the TJ, his XJ, or my XJ, both of which are '99s with a tan interior. Surprisingly, most of the plastic trim pieces are in a lot better shape than mine. I don't have room to store the whole jeep, but we'll strip what we can and toss it in the shed. We'll probably pull the whole drivetrain, seeing as we have 3 jeeps it could go into if something happens.

The old TJ axle had a track bar drop bracket welded on to the axle, so I installed an adjustable one. Other than getting the top and doors off, that's about all I've been able to do.

I've got a bunch of parts on the way, but Amazon has been really slow. Up here we're used to Prime taking 4 or 5 days, but they're saying some of my stuff is a month out. Anyone else experiencing that?

Looks like next weekend is the time for the

Wow that was nice of him to swap out the axles for you.

Yes even down here in the lower 48 stuff from Amazon even with Prime shipping takes 2-4 weeks. They say it's becasue they deem some things to be more important and essential than other things. I've started to order stuff and then see the delivery date and decided to just go buy it somewhere else.

Yes even down here in the lower 48 stuff from Amazon even with Prime shipping takes 2-4 weeks. They say it's becasue they deem some things to be more important and essential than other things. I've started to order stuff and then see the delivery date and decided to just go buy it somewhere else.

I bought the parts jeep that he gets at least the rear axle and transfer case out of, so we both think it's a fair dealWow that was nice of him to swap out the axles for you.

Yes even down here in the lower 48 stuff from Amazon even with Prime shipping takes 2-4 weeks. They say it's becasue they deem some things to be more important and essential than other things. I've started to order stuff and then see the delivery date and decided to just go buy it somewhere else.

A setback- My new house has a very steep driveway, and I parked the XJ that I daily on the incline for the first time a week ago. It rained that night, and I woke up to the passenger footwell so full of water that it was spilling into the back seat footwell. I determined that the leak was coming from the cabin air intake in the cowl. Some people online had cut open the cowl to caulk around the intake dam, but I really detest shortcuts that involve slashing up sheet metal, so that meant that the whole dash and HVAC box had to come out.

I sealed it up with silicone and put it back in, and it's drying now. We'll see if it worked in the morning...

I sealed it up with silicone and put it back in, and it's drying now. We'll see if it worked in the morning...

I bought my first home this summer, and really cut down on spending during the process, just in case anything weird came up. Now that I'm financially unconstrained again, I got an engagement ring (SHE SAID YES!) and parts in for the TJ. A buddy quipped "that pile of boxes looks like Christmas, all you're missing is a tree."

I also picked up a used 12 ton press:

Amazon managed to send me two front ring and pinion gears, so I'll have a spare in case I screw up.

I also picked up a used 12 ton press:

Amazon managed to send me two front ring and pinion gears, so I'll have a spare in case I screw up.

After a very long hiatus, I'm back in business. I've got the frame up on jackstands and the axles out, and the rear up on the healing bench.

Northridge managed to send me the 3.73-down ARB carrier for the rear, when I had ordered the 3.92-up carrier. They assured me that it would work with my gears, and sent me a chart from ARB purportedly showing as much. I pointed out to them that their chart specifically said that I had the wrong carrier, to which they replied that they'd contacted ARB and confirmed that my gears would work with the carrier. Imagine my surprise when it didn't. After some back and forth, they admitted fault and exchanged carriers.

That back-and-forth took a few weeks, but I finally got everything together tonight and took my first pattern. Pinion is a little shallow, but that's tomorrow's problem.

Northridge managed to send me the 3.73-down ARB carrier for the rear, when I had ordered the 3.92-up carrier. They assured me that it would work with my gears, and sent me a chart from ARB purportedly showing as much. I pointed out to them that their chart specifically said that I had the wrong carrier, to which they replied that they'd contacted ARB and confirmed that my gears would work with the carrier. Imagine my surprise when it didn't. After some back and forth, they admitted fault and exchanged carriers.

That back-and-forth took a few weeks, but I finally got everything together tonight and took my first pattern. Pinion is a little shallow, but that's tomorrow's problem.

DETOUR

TJ Enthusiast

You got it !!!There really aren't many pictures of TJ's without cages knocking about the internet, so I had no idea that they look DAMN GOOD cageless.

View attachment 276960View attachment 276955View attachment 276958

Wowee,

that looks sharp,

that’s right up my alley

IMHO

Ps : that’s the rims I absolutely need (they’re on my wish list)

DETOUR

TJ Enthusiast

Well Duredel

Send me your coordinates

I’ll be right over !!!

Yehawww

Come on up whenever you want to- you're closer than most everyone else on the forum!Well Duredel

Send me your coordinates

I’ll be right over !!!

Yehawww

Sorry for the lack of updates- work has again been busy and I can only spend a few hours a week in the garage. I started working on it up on my workbench, but found that the workbench was too deep and awkward to work on. I'll have to build a real axle stand someday, working on it on the floor isn't great either but at least I have access to everything.

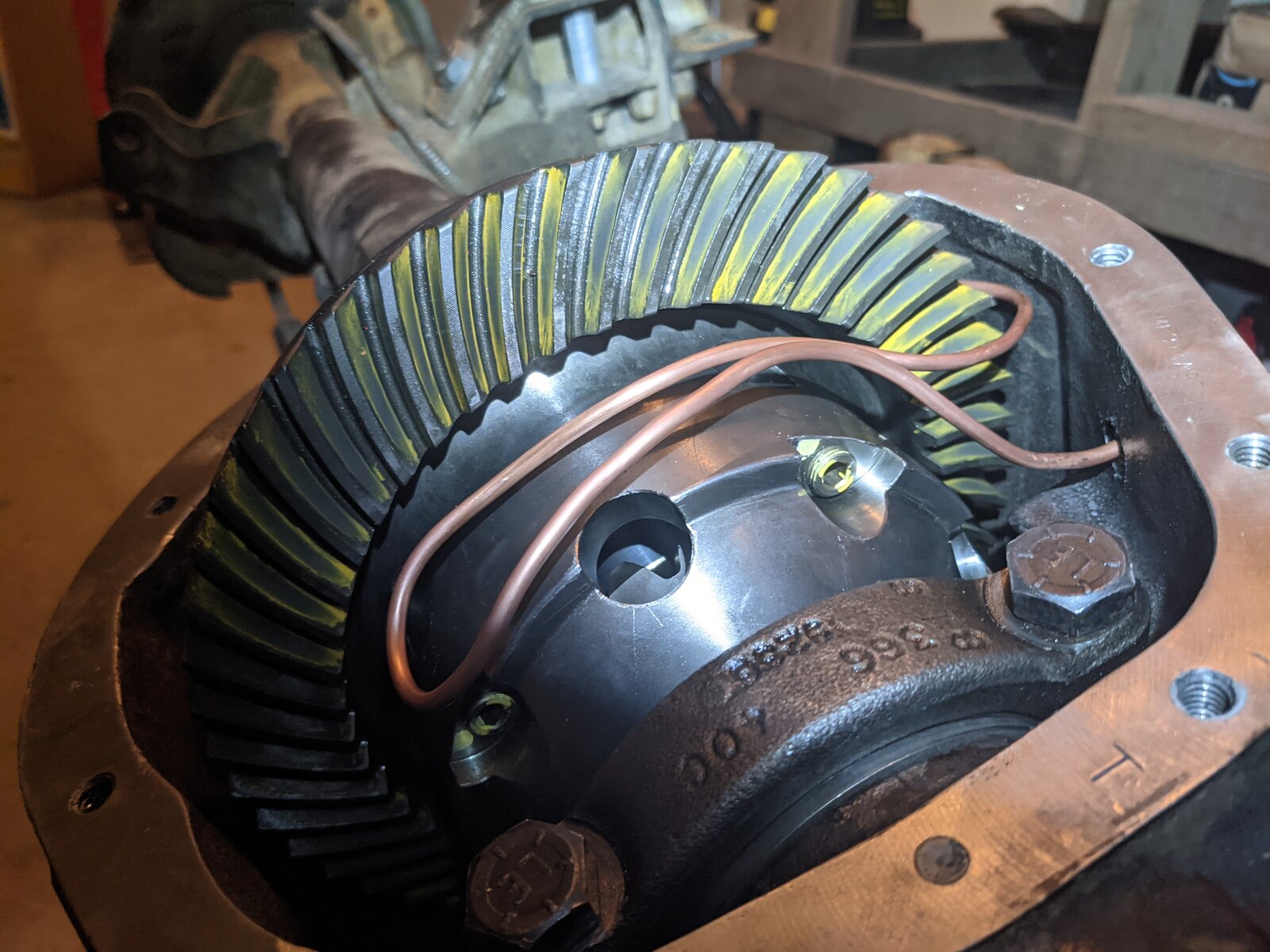

Final Pattern:

And here is all the ARB stuff:

There's a lot of extra copper line, and I'm debating whether or not I should trim it shorter or just leave it.

This was my setup for tightening the pinion nut- I can't use an impact as the Dana 44 uses shims to set pinion preload, not a crush sleeve. I've since ordered and received a yoke holder, it should make the front axle and SYE install a lot easier.

Final Pattern:

And here is all the ARB stuff:

There's a lot of extra copper line, and I'm debating whether or not I should trim it shorter or just leave it.

This was my setup for tightening the pinion nut- I can't use an impact as the Dana 44 uses shims to set pinion preload, not a crush sleeve. I've since ordered and received a yoke holder, it should make the front axle and SYE install a lot easier.

Last edited:

I've got the cover back on the rear axle- all I need to do is put the axle shafts back in, fill it with fluid, and put the gasket in. I ordered a Lubelocker gasket, but it wasn't labeled "do not fold", so my mail carrier acted accordingly:

*sigh*

I also ordered a Lubelocker gasket for the front axle, but received a very convincing knockoff- some company in China had mimicked the Lubelocker name and part number on Amazon, with broken English on the packaging to boot. So I had two gaskets to send back.

I've got the ring gear and bearings onto the new front ARB carrier, but had some trouble pressing on the inner pinion bearing. It presses just fine until the last millimeter or so, then stops dead cold. It won't budge, even with more pulling on the press than I'm comfortable with. I pressed it on and pulled it off again a few times, checking for debris or something weird, but didn't find anything. While I was burning the midnight oil working on this, I forgot to put the race on the bearing before pulling it off, bending the cage. Now I get to wait for a few days for a new bearing in return for my impatience. I think I'll try tossing the pinion in the freezer overnight, and putting the bearing in the oven for a while, and then trying to press them on. I'm almost certain it's a press-fit tolerance issue.

*sigh*

I also ordered a Lubelocker gasket for the front axle, but received a very convincing knockoff- some company in China had mimicked the Lubelocker name and part number on Amazon, with broken English on the packaging to boot. So I had two gaskets to send back.

I've got the ring gear and bearings onto the new front ARB carrier, but had some trouble pressing on the inner pinion bearing. It presses just fine until the last millimeter or so, then stops dead cold. It won't budge, even with more pulling on the press than I'm comfortable with. I pressed it on and pulled it off again a few times, checking for debris or something weird, but didn't find anything. While I was burning the midnight oil working on this, I forgot to put the race on the bearing before pulling it off, bending the cage. Now I get to wait for a few days for a new bearing in return for my impatience. I think I'll try tossing the pinion in the freezer overnight, and putting the bearing in the oven for a while, and then trying to press them on. I'm almost certain it's a press-fit tolerance issue.

While waiting for parts, I got a few other odd jobs done. One of the rear upper shock bolts had broken when removing the old shocks. I tried an easy-out with a LOT of heat to no avail. I bent the flutes on it instead of breaking it off in the hole, which was a very good warning that I should just drill it out instead. I drilled a pilot hold all the way through the broken stuck bolt, and then started with the full-size bit. I couldn't quite get the bit to go through all the way, as the hole wasn't *quite* straight through, meaning there was an interrupted cut at the top, which drill bits SUCK at. I ended up cutting the top off the broken bolt with a dremel and a 1 1/2" cutoff wheel- worked like a charm! I could then send the tap all the way through. My tap wrench wouldn't fit in the tight spot, but I found that a 12-point 5.5mm socket fit perfectly. I tapped it to the stock bolt size. I'll definitly glob on the anti-seize when I put the shocks back in!

I also got the ARB compressor mounted on the unused ABS tray and got the wires sent to where they needed to go. The tray was also re-painted to the original Patriot Blue:

As it stands right now, I'm ready to put the front HP Dana 30 together as soon as I get the new bearing in and pressed on. I also have a JB conversions Super-Short SYE kit ready to go in, which I may work on before the Dana 30 if the bearing is late to arrive. Once the axles and SYE are done, it'll be on to the HVAC system, sound deadener, and carpet.

I've ordered tires- what an ordeal to set up shipping specific tires to Alaska! They should be here in the next few weeks.

I also got the ARB compressor mounted on the unused ABS tray and got the wires sent to where they needed to go. The tray was also re-painted to the original Patriot Blue:

As it stands right now, I'm ready to put the front HP Dana 30 together as soon as I get the new bearing in and pressed on. I also have a JB conversions Super-Short SYE kit ready to go in, which I may work on before the Dana 30 if the bearing is late to arrive. Once the axles and SYE are done, it'll be on to the HVAC system, sound deadener, and carpet.

I've ordered tires- what an ordeal to set up shipping specific tires to Alaska! They should be here in the next few weeks.

It's awesome to see someone taking on significant tasks!Sorry for the lack of updates- work has again been busy and I can only spend a few hours a week in the garage. I started working on it up on my workbench, but found that the workbench was too deep and awkward to work on. I'll have to build a real axle stand someday, working on it on the floor isn't great either but at least I have access to everything.

View attachment 317691

Final Pattern:

View attachment 317688

And here is all the ARB stuff:

View attachment 317689

View attachment 317690

View attachment 317692

There's a lot of extra copper line, and I'm debating whether or not I should trim it shorter or just leave it.

This was my setup for tightening the pinion nut- I can't use an impact as the Dana 44 uses shims to set pinion preload, not a crush sleeve. I've since ordered and received a yoke holder, it should make the front axle and SYE install a lot easier.

View attachment 317699

I was looking around for a sturdy workbench and found it on Craigslist. The seller had ingeniously built the saw into the workbench, and just replaced the plywood top every year or so. $100 out the door! It even came with all the original documentation for the saw. I figure I can sell it to a museum somedayCraftsman 10" radial arm saw

. Back to Jeep stuff...

Finally got the replacement inner pinion bearing in and pressed on. I put the pinion in the freezer for an hour and the bearing in the oven at 210 for half an hour. It went *bang* when it sunk the final millimeter home- I'm guessing it was an issue with USA Standard Gear's QC. Both bearings had the exact same sticking point, meaning the pinion shaft was too large by a few thou.

I got the first pattern done- pinion too shallow by just a bit. The yoke fits very tightly onto the pinion splines, and I'd rather not whack it with a hammer any more to get it off. Heading to ACE to grab some bolts to make my yoke wrench a yoke puller after work.

I got the first pattern done- pinion too shallow by just a bit. The yoke fits very tightly onto the pinion splines, and I'd rather not whack it with a hammer any more to get it off. Heading to ACE to grab some bolts to make my yoke wrench a yoke puller after work.