i didn't cut the nuts off the cross member i drilled right through um and put another nut on top.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Broke upper rear shock bolts!

- Thread starter Erik V

- Start date

Did you then jack the body up to gain access the new nuts you installed? Or do you have a body lift already?

I do not have a body lift nor did I jack the body up. With a dremel and extension piece, you can get to the nut around the plastic wheel well liner. Get new hardware and you are all good.

If you want to cut the tub, here is a write-up with pics of a guy cutting the tub.

https://wranglertjforum.com/threads/broke-upper-rear-shock-bolts.9667/

Mine didn't... They were welded on pretty well. I needed to cut some of the weld away before the air hammer was able to break them free.An air hammer will knock the broken bolts loose in 1 minute.

I was installing a body lift at the same time, so I lifted the body off the frame for access. I can see why people cut into their tubs, but it would be an absolute last resort for me.

Here's a variation on the basic theme...

Recently (like October 2020) had a shop install new shocks (Rancho RS5000X); last week - CLUNK. Took a look and discovered upper left rear outside bolt missing. Took a closer look and ...

Here's what I found:

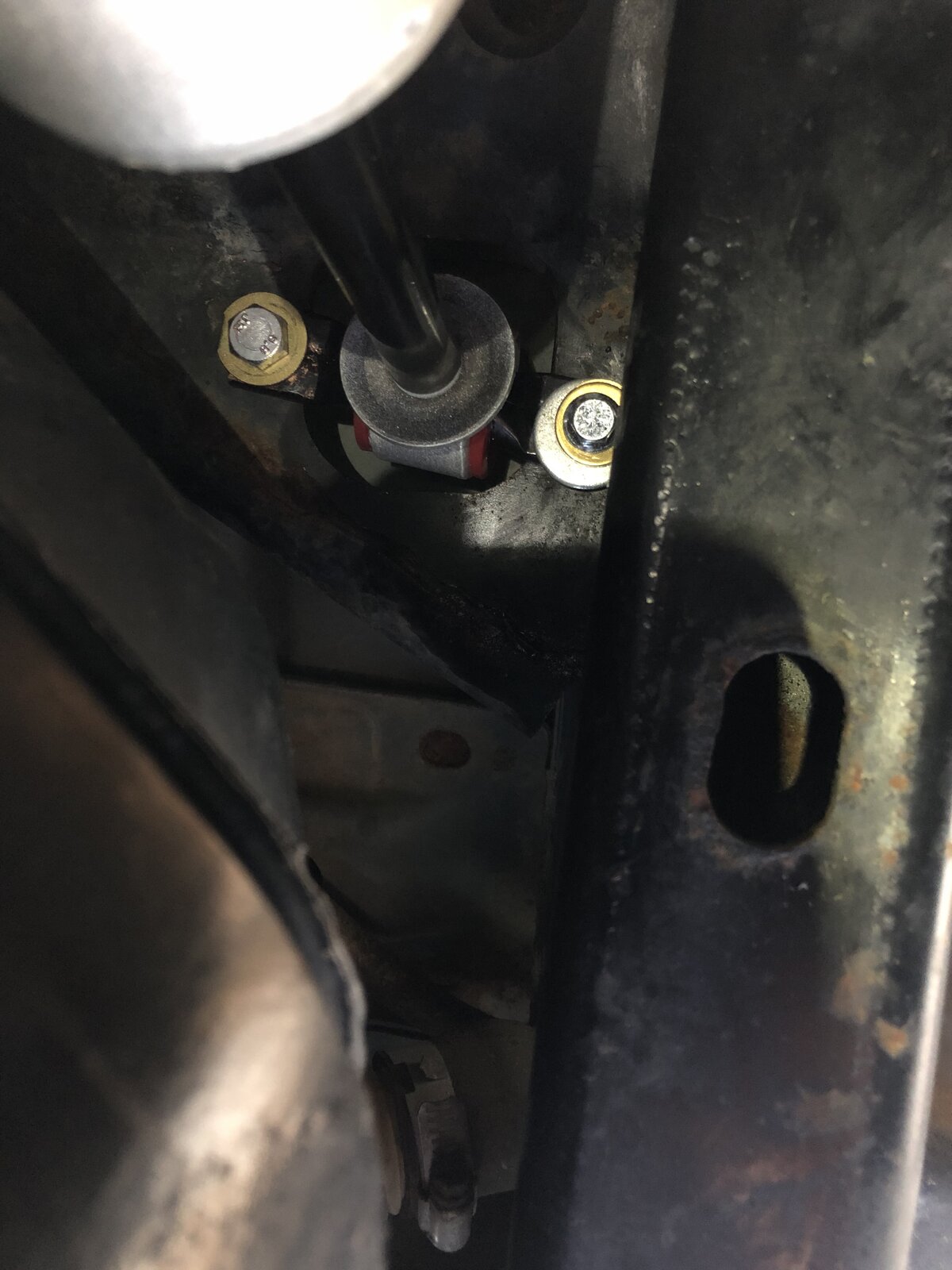

Above, the original mounting nut is intact, but was sheared off - when I don't know...the RS5000X I installed replaced older RS5000's from a previous owner. What's interesting is that hole to the upper right of the original welded nut. "Somebody" drilled and threaded or used a self-tapping bolt on that. Guess what happened next?

That's right. That arrangement didn't hold. Above is the new hole missing the bolt.

Seems to me that this was not a good solution and cutting off the OEM nuts is better that twisting the bar pin. Thoughts?

I'm undecided on whether to drop the fuel tank, lift the tub, grind the OEM nuts off and reinstall new ones, or expand the peephole and do the same from above. I haven't looked on the right side, but I'm expecting monkey business over there are well.

I need to get my hands on and see if the dremel solution works without lifting or dropping anything - I know folks have said it's doable but it seems pretty tight to me. There's no BL in place now, so not a lot of work space.

Anyway, I thought folks might find this spit and duct tape fix interesting.

Recently (like October 2020) had a shop install new shocks (Rancho RS5000X); last week - CLUNK. Took a look and discovered upper left rear outside bolt missing. Took a closer look and ...

Here's what I found:

Above, the original mounting nut is intact, but was sheared off - when I don't know...the RS5000X I installed replaced older RS5000's from a previous owner. What's interesting is that hole to the upper right of the original welded nut. "Somebody" drilled and threaded or used a self-tapping bolt on that. Guess what happened next?

That's right. That arrangement didn't hold. Above is the new hole missing the bolt.

Seems to me that this was not a good solution and cutting off the OEM nuts is better that twisting the bar pin. Thoughts?

I'm undecided on whether to drop the fuel tank, lift the tub, grind the OEM nuts off and reinstall new ones, or expand the peephole and do the same from above. I haven't looked on the right side, but I'm expecting monkey business over there are well.

I need to get my hands on and see if the dremel solution works without lifting or dropping anything - I know folks have said it's doable but it seems pretty tight to me. There's no BL in place now, so not a lot of work space.

Anyway, I thought folks might find this spit and duct tape fix interesting.

Last edited:

pwrtstdan

New Member

Ugh. Others say a dremel can be used from inside the large opening from under the jeep. I don't care about reselling mine so access through the body works well for me. Note that even with the access through the tub the nuts to the outside aren't as accessible as the nuts to the inside of the vehicle.

I would replace with a flanged nut with some blue threadlock and proper torque. This, of course, requires that you have access to the top side either between body and frame or through new hole in tub.

I would replace with a flanged nut with some blue threadlock and proper torque. This, of course, requires that you have access to the top side either between body and frame or through new hole in tub.

I'm still undecided on the path here — I'm not sure that adding a service port topside is a big deal and if there was one already built-in I doubt there'd be complaints or much discussion about this particular problem. My '03 has a peephole in that vicinity already and I wonder if it had been used to access the OEM nut/bolt arrangement with liquid wrench from the top side the (or if the peephole was a proper access plate) the problem could have been avoided altogether,

I don't care for the bar pin eliminator mod, although I've been thinking about cycling the suspension to see what difference 1/2" of travel would make to me - understood that any subsequent owner might be irritated. I do no hard-wheeling whatsoever, pot-holed forest roads with my 2.5" OME lift over 32s works fine for me.

Lifting the body and dropping the tank isn't appealing either, but neither is sitting in the driveway in January with a dremel, bad hips and questionable eyesight. I've really try to set a good example for my kid and it's been over a year since I've whipped a tool across the yard and cursed. At the same time.

Would like to get the rig back on the road though and I don't think this is the sort of repair that I'd sub out to a shop.

I don't care for the bar pin eliminator mod, although I've been thinking about cycling the suspension to see what difference 1/2" of travel would make to me - understood that any subsequent owner might be irritated. I do no hard-wheeling whatsoever, pot-holed forest roads with my 2.5" OME lift over 32s works fine for me.

Lifting the body and dropping the tank isn't appealing either, but neither is sitting in the driveway in January with a dremel, bad hips and questionable eyesight. I've really try to set a good example for my kid and it's been over a year since I've whipped a tool across the yard and cursed. At the same time.

Would like to get the rig back on the road though and I don't think this is the sort of repair that I'd sub out to a shop.

Mine popped with the first pull of the air hammer trigger every time.An air hammer will knock the broken bolts loose in 1 minute.

Did you torch it first?Mine popped with the first pull of the air hammer trigger every time.

The one nut that's busted is nearest the wheel well and hitting with an air hammer would be easy.

(If I had an air hammer and a compressor to drive it. But that's a problem easily solved - been looking to upgrade the shop compressor.)

Only used a blunt point in the vertical directly on the bolt remains. Slipped in a new nut with a fingertip.Did you torch it first?

The one nut that's busted is nearest the wheel well and hitting with an air hammer would be easy.

(If I had an air hammer and a compressor to drive it. But that's a problem easily solved - been looking to upgrade the shop compressor.)

RedneckRenegade

New Member

Hi everybody, I'm new to the forum and found this thread from a google search on this topic as I too encountered this issue when recently replacing my shocks. First off, wow what a great forum full of fellow TJ enthusiasts like me! I've got a '06 Rubicon and love it.

After reading this thread and a half dozen or so others on the same topic, I thought I'd share my experience with the broken bolt problem as well. Having very little free time due to family/life/work, I hastily attempted to remove the rear upper shock mount bolts after only a brief pre-treatment with penetrating oil, foolishly thinking "it won't happen to me, I'll be very careful" (hah)...

One bolt on each side broke (driver side inboard and passenger side outboard). Rather than cut an access hole in the body, I went the drilling route, which took 6 hours per side/bolt and consumed several carbide-tipped masonry bits and cobalt steel bits (only way I could make progress was to rotate bit type and size every 15-30 min or so).

Also nearly broke my cordless drill and eventually switched to a cheap corded drill that was difficult to use without a variable speed option. Real fun. I can't believe how hard it is to drill through these bolts, it's like they're made of out of diamond. Stacking wood boards under my arm helped with generating force/leverage but it was still an exhausting ordeal.

Once drilled through I did what a previous member mentioned to one side — added a nut on top of the existing welded nut. On the other side, I had to Dremel-off the welded nut and then very carefully insert a new nut held in place with vice grips while I fished a new bolt through the hole to align with the nut. Will be very difficult to remove/tighten/replace if ever needed later on.

My advice to anyone reading this thread that hasn't started on the bolt removal yet — please take this problem seriously, you'll be happy you did if they come out without breaking due to wise application of penetrating oil for several days beforehand. If they still break and you don't want to cut an access hole in the tub, drilling is definitely possible but be prepared for a brutal process and lots of bit consumption.

Maybe someone can advise on a specific bit brand/material that actually would hold up to this process better? I tried several common name brands from a local hardware store, and none of them survived the process. Pretty incredible hardened steel in these bolts.. Here's a pic of one side with the new bolts/shock installed.

After reading this thread and a half dozen or so others on the same topic, I thought I'd share my experience with the broken bolt problem as well. Having very little free time due to family/life/work, I hastily attempted to remove the rear upper shock mount bolts after only a brief pre-treatment with penetrating oil, foolishly thinking "it won't happen to me, I'll be very careful" (hah)...

One bolt on each side broke (driver side inboard and passenger side outboard). Rather than cut an access hole in the body, I went the drilling route, which took 6 hours per side/bolt and consumed several carbide-tipped masonry bits and cobalt steel bits (only way I could make progress was to rotate bit type and size every 15-30 min or so).

Also nearly broke my cordless drill and eventually switched to a cheap corded drill that was difficult to use without a variable speed option. Real fun. I can't believe how hard it is to drill through these bolts, it's like they're made of out of diamond. Stacking wood boards under my arm helped with generating force/leverage but it was still an exhausting ordeal.

Once drilled through I did what a previous member mentioned to one side — added a nut on top of the existing welded nut. On the other side, I had to Dremel-off the welded nut and then very carefully insert a new nut held in place with vice grips while I fished a new bolt through the hole to align with the nut. Will be very difficult to remove/tighten/replace if ever needed later on.

My advice to anyone reading this thread that hasn't started on the bolt removal yet — please take this problem seriously, you'll be happy you did if they come out without breaking due to wise application of penetrating oil for several days beforehand. If they still break and you don't want to cut an access hole in the tub, drilling is definitely possible but be prepared for a brutal process and lots of bit consumption.

Maybe someone can advise on a specific bit brand/material that actually would hold up to this process better? I tried several common name brands from a local hardware store, and none of them survived the process. Pretty incredible hardened steel in these bolts.. Here's a pic of one side with the new bolts/shock installed.

Last edited:

Good to know. I wonder if drilling bigger, and adding nutserts would fix the issue, then use bar-pin eliminators to never have to worry about it ever again would work. I have been religiously adding krill oil every weekend for the past three months.Hi everybody, I'm new to the forum and found this thread from a google search on this topic as I too encountered this issue when recently replacing my shocks. First off, wow what a great forum full of fellow TJ enthusiasts like me! I've got a '06 Rubicon and love it.

After reading this thread and a half dozen or so others on the same topic, I thought I'd share my experience with the broken bolt problem as well. Having very little free time due to family/life/work, I hastily attempted to remove the rear upper shock mount bolts after only a brief pre-treatment with penetrating oil, foolishly thinking "it won't happen to me, I'll be very careful" (hah)...

One bolt on each side broke (driver side inboard and passenger side outboard). Rather than cut an access hole in the body, I went the drilling route, which took 6 hours per side/bolt and consumed several carbide-tipped masonry bits and cobalt steel bits (only way I could make progress was to rotate bit type and size every 15-30 min or so).

Also nearly broke my cordless drill and eventually switched to a cheap corded drill that was difficult to use without a variable speed option. Real fun. I can't believe how hard it is to drill through these bolts, it's like they're made of out of diamond. Stacking wood boards under my arm helped with generating force/leverage but it was still an exhausting ordeal.

Once drilled through I did what a previous member mentioned to one side — added a nut on top of the existing welded nut. On the other side, I had to Dremel-off the welded nut and then very carefully insert a new nut held in place with vice grips while I fished a new bolt through the hole to align with the nut. Will be very difficult to remove/tighten/replace if ever needed later on.

My advice to anyone reading this thread that hasn't started on the bolt removal yet — please take this problem seriously, you'll be happy you did if they come out without breaking due to wise application of penetrating oil for several days beforehand. If they still break and you don't want to cut an access hole in the tub, drilling is definitely possible but be prepared for a brutal process and lots of bit consumption.

Maybe someone can advise on a specific bit brand/material that actually would hold up to this process better? I tried several common name brands from a local hardware store, and none of them survived the process. Pretty incredible hardened steel in these bolts.. Here's a pic of one side with the new bolts/shock installed.

View attachment 231262

Dremel with a cutoff wheel and you can have the welded nuts cut off the cross member in a hour or less and then just drop in new bolts. Easy fix.Good to know. I wonder if drilling bigger, and adding nutserts would fix the issue, then use bar-pin eliminators to never have to worry about it ever again would work. I have been religiously adding krill oil every weekend for the past three months.

I am sure there are better bits that would take less than 6 hours. I dumped this project to my mechanic and he drilled them out and replaced the shocks for $150 and their labor rates are a $110/hour.Hi everybody, I'm new to the forum and found this thread from a google search on this topic as I too encountered this issue when recently replacing my shocks. First off, wow what a great forum full of fellow TJ enthusiasts like me! I've got a '06 Rubicon and love it.

After reading this thread and a half dozen or so others on the same topic, I thought I'd share my experience with the broken bolt problem as well. Having very little free time due to family/life/work, I hastily attempted to remove the rear upper shock mount bolts after only a brief pre-treatment with penetrating oil, foolishly thinking "it won't happen to me, I'll be very careful" (hah)...

One bolt on each side broke (driver side inboard and passenger side outboard). Rather than cut an access hole in the body, I went the drilling route, which took 6 hours per side/bolt and consumed several carbide-tipped masonry bits and cobalt steel bits (only way I could make progress was to rotate bit type and size every 15-30 min or so).

Also nearly broke my cordless drill and eventually switched to a cheap corded drill that was difficult to use without a variable speed option. Real fun. I can't believe how hard it is to drill through these bolts, it's like they're made of out of diamond. Stacking wood boards under my arm helped with generating force/leverage but it was still an exhausting ordeal.

Once drilled through I did what a previous member mentioned to one side — added a nut on top of the existing welded nut. On the other side, I had to Dremel-off the welded nut and then very carefully insert a new nut held in place with vice grips while I fished a new bolt through the hole to align with the nut. Will be very difficult to remove/tighten/replace if ever needed later on.

My advice to anyone reading this thread that hasn't started on the bolt removal yet — please take this problem seriously, you'll be happy you did if they come out without breaking due to wise application of penetrating oil for several days beforehand. If they still break and you don't want to cut an access hole in the tub, drilling is definitely possible but be prepared for a brutal process and lots of bit consumption.

Maybe someone can advise on a specific bit brand/material that actually would hold up to this process better? I tried several common name brands from a local hardware store, and none of them survived the process. Pretty incredible hardened steel in these bolts.. Here's a pic of one side with the new bolts/shock installed.

View attachment 231262

All of them should come out if anti-sleaze is used. Cross pin eliminators would make the process easier in the future.

Nextrail

New Member

Cut mine off and replace with new bolt and nut combo, easierish in the future if you need to replace

EasyPrey

New Member

One reason to not use BPEs is that they'll shorten the shock travel distance.Why not just weld in the bar pin eliminator instead of all the drilling and cutting?

EasyPrey

New Member

Well, if your welds are normal I guess. On mine the welding spots were kind of big, so I had to lift the tub. To get the hand chisel in place, because the Dremel Cutoff Wheel is a quarter of an inch too small. At least on my Jeep.Dremel with a cutoff wheel and you can have the welded nuts cut off the cross member in a hour or less and then just drop in new bolts. Easy fix.