First time regearing an axle. Watched a lot of videos, read books etc but have a few questions and a problem.

This is a stock Dana 44 out of a 2006 LJ. The carrier shims were on the outside of the carrier bearing races. The driver side (carrier side) was .143” and the passenger side (ring gear side) was .121”.

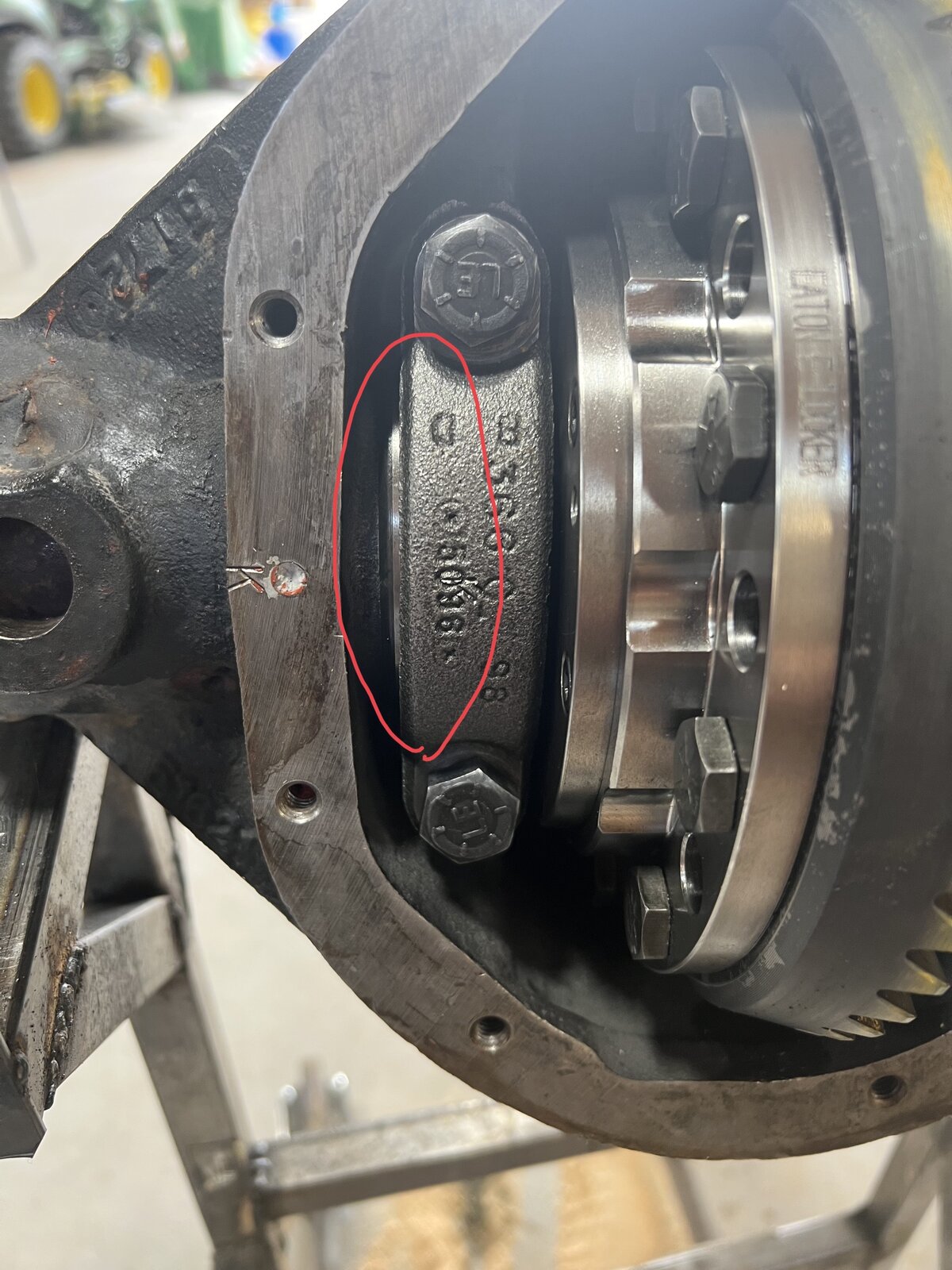

I am putting an Eaton electric locker and bought new gears from Yukon (4.56). Torqued the ring gear bolts to 55ft-lbs. Triple checked them.

With the original shims, I had 0 backlash. The Yukon kit only came with shims to go between the carrier and bearing. What I ended up with is the original shim on the passenger side, and ~.100” (have to measure exactly) between the driver side bearing and carrier.

That got the backlash within spec — depending on where on the ring gear I’m measuring. I’m seeing anywhere from .007” to .003” backlash.

Questions:

1. Is this the proper way to shim things? I ask because the bearing race on the driver side sticks out past the bearing cap now. I did try keeping both factory shims and adding a few shims on the passenger side, but that seemed way too tight.

2. I’m using setup bearings on the carrier and I don’t have enough extra shims to add preload to the carrier. It slides in and out fairly easily. I do have to tap in the passenger side shim. Could this be the cause of the excessive runout I’m seeing?

Thanks for the help. Things seemed like they were progressing well until this hiccup.

This is a stock Dana 44 out of a 2006 LJ. The carrier shims were on the outside of the carrier bearing races. The driver side (carrier side) was .143” and the passenger side (ring gear side) was .121”.

I am putting an Eaton electric locker and bought new gears from Yukon (4.56). Torqued the ring gear bolts to 55ft-lbs. Triple checked them.

With the original shims, I had 0 backlash. The Yukon kit only came with shims to go between the carrier and bearing. What I ended up with is the original shim on the passenger side, and ~.100” (have to measure exactly) between the driver side bearing and carrier.

That got the backlash within spec — depending on where on the ring gear I’m measuring. I’m seeing anywhere from .007” to .003” backlash.

Questions:

1. Is this the proper way to shim things? I ask because the bearing race on the driver side sticks out past the bearing cap now. I did try keeping both factory shims and adding a few shims on the passenger side, but that seemed way too tight.

2. I’m using setup bearings on the carrier and I don’t have enough extra shims to add preload to the carrier. It slides in and out fairly easily. I do have to tap in the passenger side shim. Could this be the cause of the excessive runout I’m seeing?

Thanks for the help. Things seemed like they were progressing well until this hiccup.