You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Higher horses, higher revs & even higher torque, a streetable LJ engine swap

- Thread starter toximus

- Start date

Got caught up a bit late here. Glad you got the case. How is it progressing?

Unfortunately no progress. I've been working 80-90 hour work weeks and am exhausted at the end of each day. I wrapped up a big work project last night at midnight and it's looking like my hours can return to normal. I also took the next 4 days off of work so once I recover I'll hopefully have some progress to show.

Gotcha. I got to wheel my new Atlas once and it was glorious and better than I imagined. My rear Dana 44 is bent and I think the extra torque help fully kill my ARB and axle shaft splines. So I'm on the hunt for housings as I already scored a Detroit locker and shafts from Blaine.Unfortunately no progress. I've been working 80-90 hour work weeks and am exhausted at the end of each day. I wrapped up a big work project last night at midnight and it's looking like my hours can return to normal. I also took the next 4 days off of work so once I recover I'll hopefully have some progress to show.

Were those the 44 shafts and locker?Gotcha. I got to wheel my new Atlas once and it was glorious and better than I imagined. My rear Dana 44 is bent and I think the extra torque help fully kill my ARB and axle shaft splines. So I'm on the hunt for housings as I already scored a Detroit locker and shafts from Blaine.

Yes, they ended up being 33 spline shafts, but I'm fine with that. My stuff broke because of the bent housing, not the strength of the ARB or my existing 33 spline shaft.Were those the 44 shafts and locker?

First order of business is bolting on the accessories to the engine. My thought here is by doing so I'll have a good idea of the final physical size and get more familiar with the engine outside of the Jeep.

Because I'll be operating my Jeep (and thus engine) at various extreme angles I decided to add in rear steam vents to the block. This video helps explain the reason why LS engines need steam vents:

Later model LS engines like mine block off the rear steam vents with a rivet of sorts:

Because I'll be operating my Jeep (and thus engine) at various extreme angles I decided to add in rear steam vents to the block. This video helps explain the reason why LS engines need steam vents:

Later model LS engines like mine block off the rear steam vents with a rivet of sorts:

To get the plugs out I decided to place my engine on a stand and rotate it upside down to drill them out. This way all of the chips would fall out vs falling into the coolant passage.

I bought a cheapy Harbor Freight 750lb engine stand (which I would not recommend if you want to use it long term... it's very difficult to turn and doesn't feel very stable.).

To get the engine onto the stand I used a lift plate from Motion Raceworks (https://www.motionraceworks.com/products/gen-4-ls2-ls3-ls7-lsx-engine-lift-plate) and the hoist.

Intake removed:

After I removed the valley cover I bolted on the lift plate:

The rear vent plugs:

I bolted the engine to the stand with class 10.9 M10x1.5 70mm long bolts (https://www.mcmaster.com/93474A228/). And then rotisseried the engine upside down and drilled the plugs out. I'm pretty sure GM pre-fills these crate engines with oil because a few quarts went all over my garage floor...

With the engine upright again I loosely bolted on a steam vent kit I bought from from Motion Raceworks (https://www.motionraceworks.com/pro...ossover-steam-kit-for-low-pro-plastic-intakes):

For the front I decide to leave the OEM LS3 vents on for now. Once I have a better idea of how I'm routing hoses I'll make a decision if I'm replacing them for the billet ones like the rear.

To give myself a head start with making my own motor mounts, I bought engine side plates from Kartek (KTK34191). Because the crate engine doesn't come with many of the necessary bolts, I decided to dress her up a little bit and attached the plates to the block with stainless steel bolts from ARP (434-3103).

Today ended sooner than I would have liked with a Dawn dish soap shower... But, at least the transfer case is out... More tomorrow.

A Dawn dish soap shower you say? I've had many of those myself

It comes after an ATF shower.

It comes after an ATF shower.

This thing will be done by the time the Moab trip rolls around next year, right?

Brianj5600

TJ Expert

I love that video. I also like the one Matt did where he does a Mr. Rogers impersonation. And he sounds exactly like Fred Rogers.

Here's the 42rle next to the 6L80e:

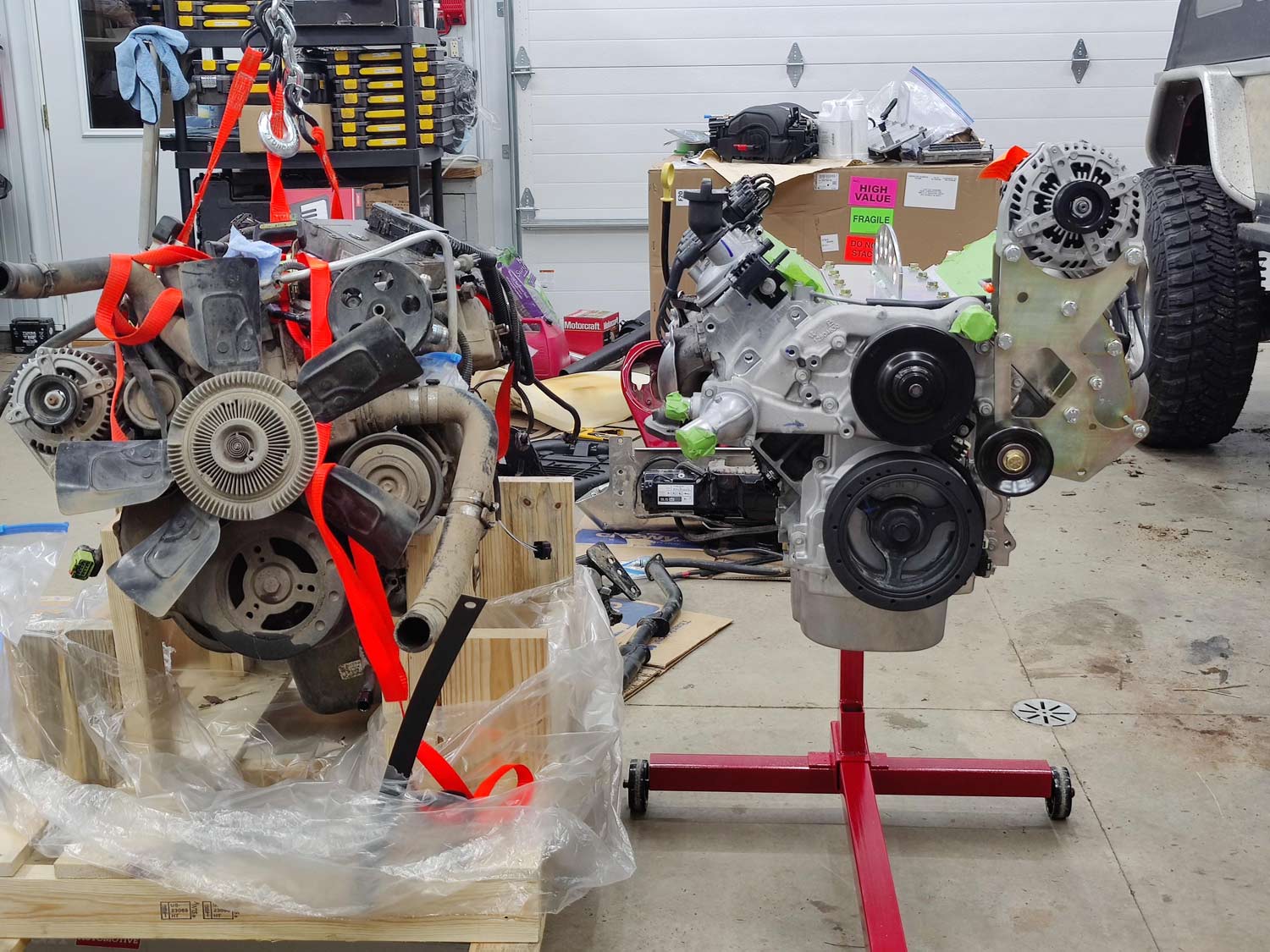

Out with the old:

I'm might have to bring the pressure washer into the garage...

From the rear you can see how narrow the line 6 is:

That's always an amazing feeling when you yank that engine out. Have fun with the mock up to follow.

Now with the engine out you can easily seal up that leaky cowl drainView attachment 203967

Here's the 42rle next to the 6L80e:

View attachment 203968

View attachment 203969

Out with the old:

View attachment 203970

View attachment 203971

I'm might have to bring the pressure washer into the garage...

View attachment 203972

From the rear you can see how narrow the line 6 is:

View attachment 203973

Tomorrow's supposed to be a steamy 50F so I put off washing the engine bay and cleaned up the garage today and did some fun driveline comparisons instead. There is many size and proportion differences between the two and both aren't aligned the same in these pictures, and thus this comparison isn't meant to be exact science, rather just a brief look with rough measurements.

Measuring from the front of the accessory belt to the face of the rear yoke:

How that breaks down for the stock driveline:

How that breaks down for the new GM driveline:

The Jeep raised up quite a bit without the weight of the driveline:

In this picture, the 6L80E pan gasket is on the bottom with the 42RLE pan on top. The 6L80E keeps the pan under the transmission while the 42RLE rotates the pan to be wider. Because of this I think I'll have some more room for the front driveshaft.

Measuring from the front of the accessory belt to the face of the rear yoke:

- The total length of the stock 4.0L + 42RLE + NP231 is approximately 68-1/2".

- The total length of the LS3 + 6L80E + Atlas 2 is approximately 63-3/4".

How that breaks down for the stock driveline:

- 4.0L - 30-1/2"

- 42RLE - 24-1/4"

- NP231 (with SSSYE) - 13-3/4"

How that breaks down for the new GM driveline:

- LS3 (with corvette belt spacing) - 24-3/4"

- 6L80E (includes 4" adapter) - 27"

- Atlas 2 - 11-3/4"

The Jeep raised up quite a bit without the weight of the driveline:

In this picture, the 6L80E pan gasket is on the bottom with the 42RLE pan on top. The 6L80E keeps the pan under the transmission while the 42RLE rotates the pan to be wider. Because of this I think I'll have some more room for the front driveshaft.

- 42RLE pan width: 14-1/2"

- 6L80E pan width: 12"