Although this is posted in my build thread, I'm placing it here for others that might not look there. This post is specific to a small group of forum members that are running the Yukon, WU-07, Small Hub Kit. However, those wanting to run JL/JT wheels on a stock hub bearing can do so much easier than what's posted here. The only thing you'll need to pay attention to is the first couple paragraphs, which outlines some very important differences between the JK and JL/JT wheels.

Here's what I learned along the way to installing JL or JT wheels on my TJ. The first thing to note is that for those that don't know, there is an important difference between JK and JL/JT wheels. Although both are a 5 on 5 bolt pattern, the JK wheels use the same size wheel stud, 1/2x20, as the TJ. The JT and JL use a much larger 14mm x 1.50 stud. There is a split year in '18, but the year break down looks like this:

- 07-18 Jeep JK = 1/2 in. x 20

- 18-22 Jeep JL/JT = 14mm x 1.50

This translates to a 19mm socket size for the TJ and JK lug nuts, but a much larger 22mm socket for the JL/JT. The more important difference is the the size of the lug nuts conical base. Warning, a smaller TJ and JK lug nut will not work properly on a JL/JT wheel, so this presents a problem when using JL/JT wheels on a TJ. Fortunately, thanks to @CodaMan, there is a slightly larger, 13/16 1/2x20 lug nut that works with the JL/JT wheels. The pictures below show the difference in lug nut sizes and how they are seated in the JT wheels I used. The numbers shown are measurements of the widest part of the conical base.

It's a little hard to tell, but the picture with the silver lug nut is a stock TJ version. When torqued down, it sits slightly below the top surface of the lug nut hole. The black lug nut is a 1/2x20 also, but requires a 13/16 socket and has a larger base. When torqued, it sits slightly above the mounting hole. This means more surface area is in contact with the wheel. This 13/16, larger conical base, lug nut can be found in the link below.

https://www.amazon.com/gp/product/B07QM9WD6B/?tag=wranglerorg-20

With the lug nut problem solved, this next part focuses on enlarging the wheels center bore, to fit the WU-07. The original 1.25" adapters I used had a bore of 2.8". This required use of a 2 3/4" hole saw, wrapped with 14 complete wraps of blue painters tape to make up the difference between the 2.80" adapter bore and 2.75" hole saw. One important note here is that the adapters used are lug centric and not hub centric. Reason being is if you used a hub centric adapter, you'd end up boring out the hub centric portion and just make unnecessary work for yourself. Here is the lug centric adapter I used on the first experiment.

https://www.amazon.com/dp/B08BJL78SS/?tag=wranglerorg-20

Using the tape as a way to keep the hole saw centered, drill out the hole. As a note, 14 wraps is just a general guide and you may need to adjust the number. The trick is to get enough wraps to make the saw snug, but not so tight it bound up. Care should be taken when drilling to stop and frequently clean out the shavings, I found this process, although a little longer, made for cleaner cuts.

This gives you a general idea about how much material you are removing.

This is what it looks like when the hole is done.

And here is how you can check your work. When done, I measured exactly 8" across each wheel stud hole, measuring to the outside lip of the wheel. FWIW, the 8" number isn't as important as ensuring each measurement is consistent!

Once I had the first one done I mounted up an extra hub to test my work. If any adjustments are needed, a carbide bit can be used to reshape the outer part of the bore.

With the center bore checked against the hub kit, I mounted up the adapter to the rear axle and test fit the tire.

An important note when mounting the adapters for the final installation. It's recommended that you use Locktite 271 on each wheel stud that attaches the adapter to the axle. With Locktite applied, on a clean stud, torque the adapters to the factory specification

https://www.amazon.com/dp/B004DWUN5S/?tag=wranglerorg-20

Once the adapters are installed, mount the wheels and torque them to the factory specification, using the 13/16 lug nuts.

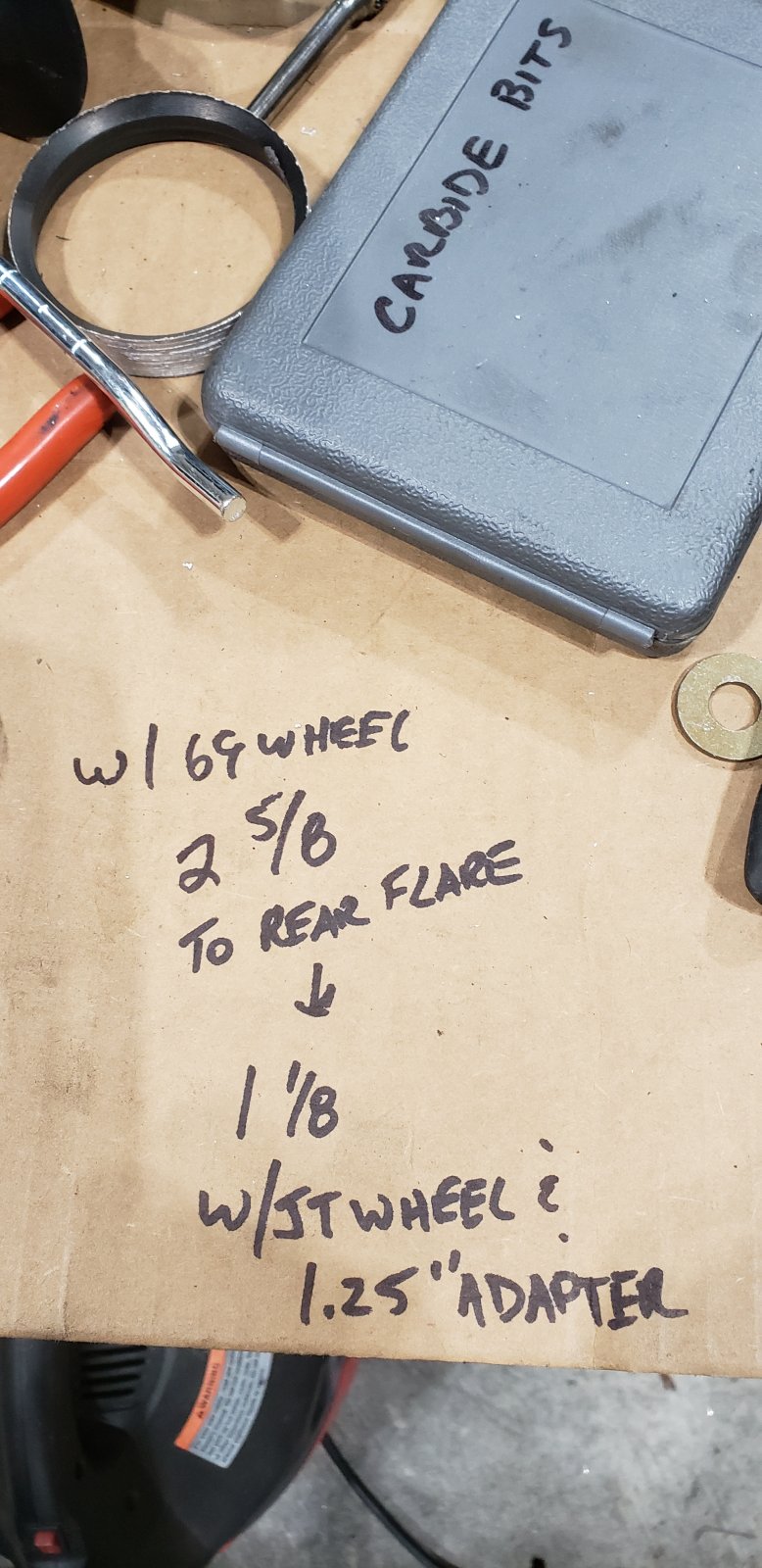

Then came the final measurement. Before the swap my 3.75" BS Pro Comp 7069 wheel stuck out 2 5/8" past the fender flare. After the install, the JT wheel and 255/75R17 combination only stuck out 1 1/8", which meant I pulled the wheel in 1.5" and it fit much better.

With original Pro Comp Wheel and 31x10.50R15

With stock JT wheel and 255/75R17 combination

Here's what I learned along the way to installing JL or JT wheels on my TJ. The first thing to note is that for those that don't know, there is an important difference between JK and JL/JT wheels. Although both are a 5 on 5 bolt pattern, the JK wheels use the same size wheel stud, 1/2x20, as the TJ. The JT and JL use a much larger 14mm x 1.50 stud. There is a split year in '18, but the year break down looks like this:

- 07-18 Jeep JK = 1/2 in. x 20

- 18-22 Jeep JL/JT = 14mm x 1.50

This translates to a 19mm socket size for the TJ and JK lug nuts, but a much larger 22mm socket for the JL/JT. The more important difference is the the size of the lug nuts conical base. Warning, a smaller TJ and JK lug nut will not work properly on a JL/JT wheel, so this presents a problem when using JL/JT wheels on a TJ. Fortunately, thanks to @CodaMan, there is a slightly larger, 13/16 1/2x20 lug nut that works with the JL/JT wheels. The pictures below show the difference in lug nut sizes and how they are seated in the JT wheels I used. The numbers shown are measurements of the widest part of the conical base.

It's a little hard to tell, but the picture with the silver lug nut is a stock TJ version. When torqued down, it sits slightly below the top surface of the lug nut hole. The black lug nut is a 1/2x20 also, but requires a 13/16 socket and has a larger base. When torqued, it sits slightly above the mounting hole. This means more surface area is in contact with the wheel. This 13/16, larger conical base, lug nut can be found in the link below.

https://www.amazon.com/gp/product/B07QM9WD6B/?tag=wranglerorg-20

With the lug nut problem solved, this next part focuses on enlarging the wheels center bore, to fit the WU-07. The original 1.25" adapters I used had a bore of 2.8". This required use of a 2 3/4" hole saw, wrapped with 14 complete wraps of blue painters tape to make up the difference between the 2.80" adapter bore and 2.75" hole saw. One important note here is that the adapters used are lug centric and not hub centric. Reason being is if you used a hub centric adapter, you'd end up boring out the hub centric portion and just make unnecessary work for yourself. Here is the lug centric adapter I used on the first experiment.

https://www.amazon.com/dp/B08BJL78SS/?tag=wranglerorg-20

Using the tape as a way to keep the hole saw centered, drill out the hole. As a note, 14 wraps is just a general guide and you may need to adjust the number. The trick is to get enough wraps to make the saw snug, but not so tight it bound up. Care should be taken when drilling to stop and frequently clean out the shavings, I found this process, although a little longer, made for cleaner cuts.

This gives you a general idea about how much material you are removing.

This is what it looks like when the hole is done.

And here is how you can check your work. When done, I measured exactly 8" across each wheel stud hole, measuring to the outside lip of the wheel. FWIW, the 8" number isn't as important as ensuring each measurement is consistent!

Once I had the first one done I mounted up an extra hub to test my work. If any adjustments are needed, a carbide bit can be used to reshape the outer part of the bore.

With the center bore checked against the hub kit, I mounted up the adapter to the rear axle and test fit the tire.

An important note when mounting the adapters for the final installation. It's recommended that you use Locktite 271 on each wheel stud that attaches the adapter to the axle. With Locktite applied, on a clean stud, torque the adapters to the factory specification

https://www.amazon.com/dp/B004DWUN5S/?tag=wranglerorg-20

Once the adapters are installed, mount the wheels and torque them to the factory specification, using the 13/16 lug nuts.

Then came the final measurement. Before the swap my 3.75" BS Pro Comp 7069 wheel stuck out 2 5/8" past the fender flare. After the install, the JT wheel and 255/75R17 combination only stuck out 1 1/8", which meant I pulled the wheel in 1.5" and it fit much better.

With original Pro Comp Wheel and 31x10.50R15

With stock JT wheel and 255/75R17 combination