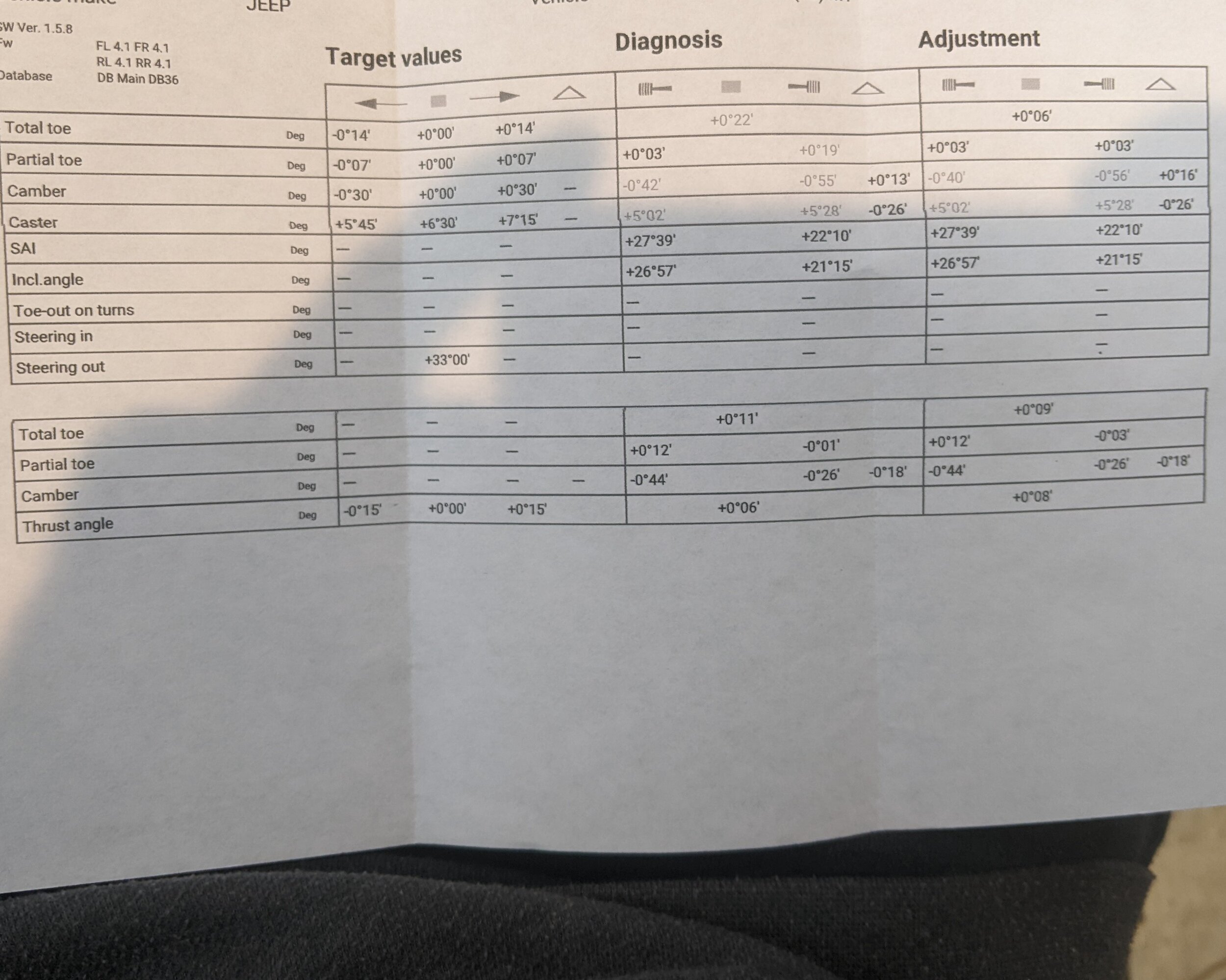

I replaced control arms, springs, shocks, track bars, hub assemblies, axle shafts, Currectlync HD Steering, SYE, and installed an antirock sway bar. I have a ton of unearned confidence, and did all the work myself with the help of YouTube and info from people on this forum. I took my LJ in today for a tire and wheel balance and an alignment, and they gave me a printout of my alignment. I have no clue what it all means on paper. Just for added confidence, or to get ridiculed, can anyone tell me if I was at least originally in the ballpark. Thanks!

Last edited: