IDK shit but i might opt to feed to the GM harness and ARB isolated from the convenience items, then spit them between lights vs warm buns and music.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is grounding 230 amps through the tub a bad idea?

- Thread starter toximus

- Start date

I've run 370 amp alternators on other cars before without issue. As long as the battery to body ground and block ground are in good condition it is no issue.

For upgrading the block ground, it's actually better to squash the ring terminal under an alternator bolt. That way the current has a much shorter path to flow.

For a 240 amp alternator, 1/0 is more than sufficient and possibly a bit overkill. At about a 270 amp alternator, you'll need 1/0. 2/0 is recommended for a 370 amp alternator.

I've been tempted to put in a 270 or 370 amp alternator in my TJ to increase winch power but have never gotten around to it. It would either be a Singer or a DC Power alternator.

https://www.dcpowerinc.com/products/13912-370-xp-jeep-wrangler-2000-4-0l-i6

For upgrading the block ground, it's actually better to squash the ring terminal under an alternator bolt. That way the current has a much shorter path to flow.

For a 240 amp alternator, 1/0 is more than sufficient and possibly a bit overkill. At about a 270 amp alternator, you'll need 1/0. 2/0 is recommended for a 370 amp alternator.

I've been tempted to put in a 270 or 370 amp alternator in my TJ to increase winch power but have never gotten around to it. It would either be a Singer or a DC Power alternator.

https://www.dcpowerinc.com/products/13912-370-xp-jeep-wrangler-2000-4-0l-i6

IDK shit but i might opt to feed to the GM harness and ARB isolated from the convenience items, then spit them between lights vs warm buns and music.

But if the GM harness and ARB stop working, at least I'll have tunes and warm buns.

You guys are right, I went too large on a lot of that. Downsizing now. This is why I brought it up before ordering.

was thinkin backwards myself, wouldn't want a convenience function shorting and possibly taking out a more important component. or even just for diagnostic simplification based on sys's isolation.But if the GM harness and ARB stop working, at least I'll have tunes and warm buns.

There's not all that much difference between 1/0 and 2AWG, so realistically, either is fine. 1/0 would give you some headroom in case you ever install a high power alternator. You can actually run a 370 on 1/0, just with a tony amount of additional voltage loss.

That seems to line up with what Mechman says too. Although, they skip 2ga. I'm only running about 2ft of cable.

https://www.mechman.com/content/instructional-pdfs/General-alternator-installation-instructions.pdf

That makes sense. Mechman was the maker of the 370a alternator I had in my F150. Like Singer, most of them are based on Denso cores.That seems to line up with what Mechman says too. Although, they skip 2ga. I'm only running about 2ft of cable.

https://www.mechman.com/content/instructional-pdfs/General-alternator-installation-instructions.pdf

You're not going to see a whole lot of voltage drop from the wire itself. What really matters is the attention you pay to make sure the terminals get very good contact both at the crimp and at the ring end. I always buy ring terminals either undrilled or with small holes, and then enlarge the holes to the size of the stud with a step drill.

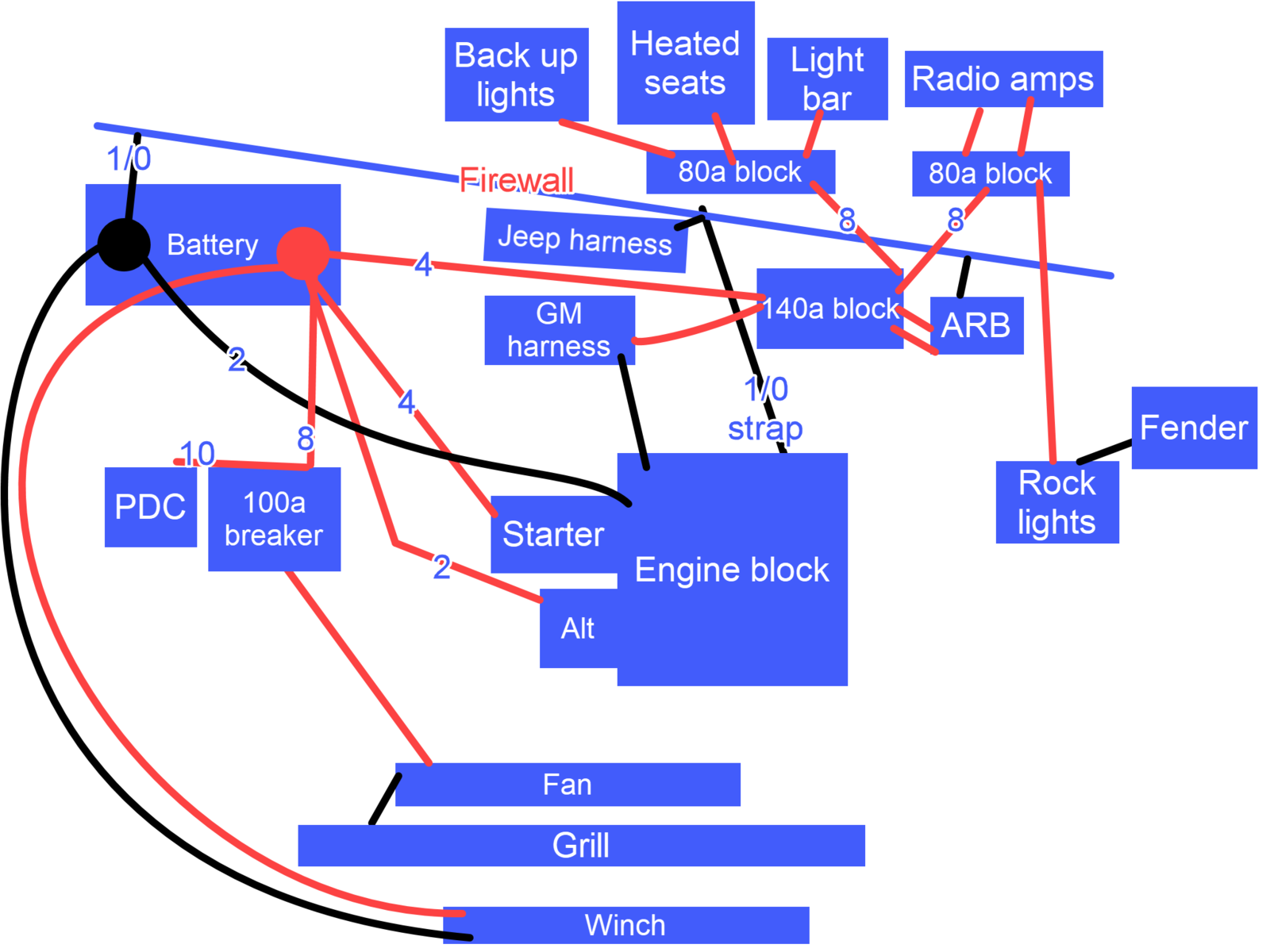

Latest revision.

The highest draws that the PDC runs are the (led) headlights, wipers, interior lights, and radio head unit (touch screen). Removed from stock is the engine ignition, fuel pump, and speakers. Hence the smaller than stock 10ga.

The 1/0 between the engine, firewall, and battery are probably overkill still. The 4ga to the 140a block might be a little overkill too but will prevent electrical quality issues to the GM harness (it'll package nicer than wiring it to the battery).

I'll leave enough wire length on the GM harness to route it back to the battery if needed.

Any ideas for neatly positioning the 5 wires connecting to the positive terminal?

The highest draws that the PDC runs are the (led) headlights, wipers, interior lights, and radio head unit (touch screen). Removed from stock is the engine ignition, fuel pump, and speakers. Hence the smaller than stock 10ga.

The 1/0 between the engine, firewall, and battery are probably overkill still. The 4ga to the 140a block might be a little overkill too but will prevent electrical quality issues to the GM harness (it'll package nicer than wiring it to the battery).

I'll leave enough wire length on the GM harness to route it back to the battery if needed.

Any ideas for neatly positioning the 5 wires connecting to the positive terminal?

240 is a lot... Like more than most of the welders we have in our garages. If your building for that much current, you're oversizing all your main wires, and copper is really expensive.

The reason for the 240a alternator is 2 part:

- The introduction of the electric fan.

- I'll be running a smaller than stock pulley on it (for a longer life on the high revving LS) on the alternator so I upsized to get more at idle.

Wouldn’t the smaller pulley generate more rpm/charging than a stock larger pulley and be harder for the engine to turn? Essentially the same as using the small sprocket on a rear bicycle wheel.The reason for the 240a alternator is 2 part:

- The introduction of the electric fan.

- I'll be running a smaller than stock pulley on it (for a longer life on the high revving LS) on the alternator so I upsized to get more at idle.

Bigger pulley would give engine more leverage.

You caught my error. Larger, not smaller.Wouldn’t the smaller pulley generate more rpm/charging than a stock larger pulley and be harder for the engine to turn? Essentially the same as using the small sprocket on a rear bicycle wheel.

The amperage draws you gave to be way higher than they really are and strongly believe that you really don't need that 240 amp alternator. The amp draws you gave above were what they are fused for, not what they actually draw which is typically half of the fuse size at the most. And then you'll never be drawing the sum total of them all at once, there will usually never be more than a couple of them on at the same time. Amplifiers especially seldom draw even close to their max draws unless you're in a mobile audio competition event. And a typical single electric engine fan doesn't draw that much, 15-28 amps or so. And the oversize fan pulley isn't likely to be needed either, amps drawn at idle rpms are seldom all that high. Don't add everything up and believe that's your typical current load, it's not.

The amperage draws you gave to be way higher than they really are

I agree and why I posted here to figure out the truth.

And the oversize fan pulley isn't likely to be needed either, amps drawn at idle rpms are seldom all that high.

I have no experience with this so I have to rely on those who have while I learn.

The larger *alternator pulley is at the suggestion and experience of Randy Slawson making these live. Remember, my LS3 has a redline of 6600rpm stock. With a stock pulley on the alt, that's around 21000 rpm seen at the alt which is over what they're rated for.

So if I were to put the larger pulley on a lower rated alternator, my fear is that I'd be making less power than I could be using.

An Ultra4 car can get away with a lower rated alt much easier, because they dont idle at 500rpm sitting around waiting for a buddy with everything running.

What size do I actually need? I have absolutely no idea.

I'd run with the stock pulley long enough to see that/if it's keeping the battery charged adequately. Alternators put out more amps at idle rpms than the old generators did and not everyone is aware of that. My old VW and its generator would turn its generator light red, which indicates a battery drain, whenever I came to a stop with the headlights on. I'd have to rev the engine to make the red light shut off.

I'd run with the stock pulley long enough to see that/if it's keeping the battery charged adequately. Alternators put out more amps at idle rpms than the old generators did and not everyone is aware of that. My old VW and its generator would turn its generator light red, which indicates a battery drain, whenever I came to a stop with the headlights on. I'd have to rev the engine to make the red light shut off.

Again, the larger pulley is to INCREASE life, which will DECREASE output. Because it will spin SLOWER.

Oh you meant a larger pulley on the alternator, not the drive pulley. That makes sense.Again, the larger pulley is to INCREASE life, which will DECREASE output. Because it will spin SLOWER.

It looks like you are way over complicating things, I also don’t see a reason for the high average alternator, the factory alternator should power everything fine. Most high average alternators take higher rpm to start charging so that would hurt your charging at idle. On engine conversions I wire, I add a high amperage Bosch that is turned on by the factory ignition switch. I would power up the LS system with that relay this takes the load off the factory wiring. Then I would put one fuse block for the aux items ( seats, lights etc) or I would use relays and fuses in the factory pic for these accessories. Your cooling fan should draw 20-30 amps max with maybe a little higher on start up. Heated seats under 5 amps per seat, led lights don’t draw huge amounts of power either.Latest revision.

The highest draws that the PDC runs are the (led) headlights, wipers, interior lights, and radio head unit (touch screen). Removed from stock is the engine ignition, fuel pump, and speakers. Hence the smaller than stock 10ga.

The 1/0 between the engine, firewall, and battery are probably overkill still. The 4ga to the 140a block might be a little overkill too but will prevent electrical quality issues to the GM harness (it'll package nicer than wiring it to the battery).

I'll leave enough wire length on the GM harness to route it back to the battery if needed.

Any ideas for neatly positioning the 5 wires connecting to the positive terminal?

View attachment 313648

You mentioned removing higher voltage items from the PDC. How many amps is the factory PDC supposed to be able to handle and what would be the limfac? I would imagine the cables going to it but beyond that? Bus bar powering the fuses?

40a ARB #1

40a ARB #2

30a Light bar

40a fan (still waiting to hear back with a final number on this)

15a rock lights

15a back up lights

40a speaker amp

40a subwoofer amp

Speakers and ARB would never be on at the same time.

@machoheadgames @Jerry Bransford @Mike_H I took your guys suggestions and looked into the actual draw of each while running.

| ARB #1 | 40a fuse | 14.2a draw |

| ARB #2 | 40a fuse | 14.2a draw |

| Fan | 100a breaker | 40a draw (*not official) |

| Light bar | 30a fuse | 20.71a draw |

| Rock lights (combined) | 15a fuse | 2.6a draw |

| Back up lights (combined) | 15a fuse | 2.1a draw |

| Speaker amp | 40a fuse | N/A |

| Subwoofer amp | 40a fuse | N/A |

| Heated seats (combined) | I forget | 7a draw |

My understanding is that peak is higher, hence the higher rated fuses. Although I think I could safely reduce the fuses for the rock lights and the back up lights to 5a each.

Based on this, the max aftermarket stuff will be drawing at will be 112.41a constant (again, since there's some things I'll never be running at the same time).

Any changes you guys would recommend based on this data? Thoughts on connecting the GM harness into the 4ga like I have in the diagram, will it see voltage drop compared to direct to battery?