I just replaced tie rods, track bar, drag link with all new Moog parts as talked about on this forum.

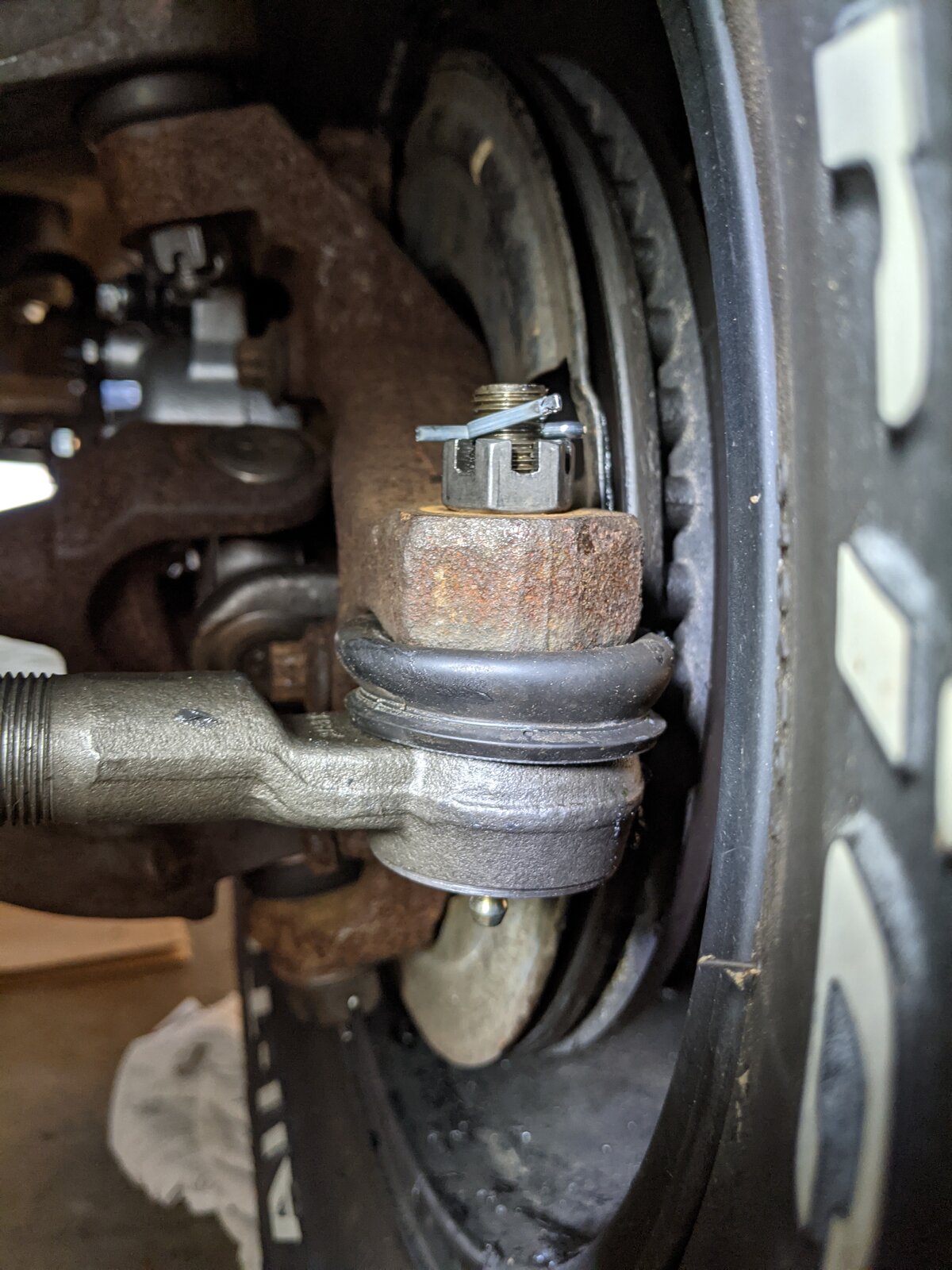

When torqued at 55 ft lbs the driver's side tie rod nut is past the hole in the bolt where the cotter pin isn't seated in the castle nut, it's above it.

The passenger's side tie rod nut seems OK.

I have removed and re-torqued and it is the same.

It appears the driver's side tie rod is closer to the knuckle, and the boot is squished/bloated.

Does this look OK to yall?

DRIVER SIDE

PASSENGER SIDE

When torqued at 55 ft lbs the driver's side tie rod nut is past the hole in the bolt where the cotter pin isn't seated in the castle nut, it's above it.

The passenger's side tie rod nut seems OK.

I have removed and re-torqued and it is the same.

It appears the driver's side tie rod is closer to the knuckle, and the boot is squished/bloated.

Does this look OK to yall?

DRIVER SIDE

PASSENGER SIDE