You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PC1P's 1998 Jeep TJ Build - "Ophelia"

- Thread starter pc1p

- Start date

Thanks man, I'm trying to get it done so I can enjoy the local trails over winter before we move up north and they are no longer in my backyard (almost quite literally!)...

View attachment 202529

For the 408, I used the SCAT Forged rotating assembly but actually used the LA style pistons since my deck was perfectly square and didn't need to be squared up. This resulted in 0.008" stick out (most Magnum pistons are in the hole some, so you have to zero-deck the block), which I compensated for with a slightly thicker Fel-Pro SD-series head gasket. Total SCR is about 10.3:1. Heads are Edelbrock 2.02" aluminum Performers. For the cam, I originally went with a mild "RV" style cam from UTAwesome Performance (Marty is the Magnum king!) but decided to save that for the 5.9L I was building for my YJ at the time. I ended up using a Comp Cam P/N 20-604-9 with an advertised duration of 264º/274º and .512/.512 lift.

I was hesitant to go bigger or with a lower LSA (this one is 112º) since I do need to keep this truck emissions friendly. On a non-stroker, this cam is right on the cusp of potentially causing sniffer-test issues, but with the bigger cubes I was fairly certain that it would be fine. Everything else is typical high-performance build stuff (roller rockers, double-roller Cloyes chain, Pacesetter ceramic shorty headers for driveline clearance, etc.). I kept the factory intake, since I need to have it match the VEIC during emissions testing every 2 years. I'm also on the factory throttle body, but only temporary (I am sending off to Rolf S. for boring out to 52mm blades).

Overall I'm happy with the performance. She starts and runs butter smooth in traffic but will light up 37"s like it's nobody's business with just a blip of the throttle. I have already pissed off a Tacoma driver and 2500 GM Brodozer at the Loop 202 on-rampThat said, without a tune, the last thing I want is to burn a hole in a piston so I really haven't pushed it too hard

I had some parts delays last year, then we took a family vacation the week before COVID hit (almost got stuck in Maui!) and then everything went nuts. By the time I got all the pieces together, summer had hit and it was well into the 100ºs. It's 65º out today and should be cool from here on out, so I'm extra focused on trying to get the TJ done so I can turn my attention to the RamCharger. I'm in the process of converting the OBD-I setup for a 97 JTEC OBD-II setup. This will retain the "look" of OBD-I (at least as far as the visual inspection goes) but will provide better emissions control while also allowing for handheld tuning via a SCT (I'll be using Marty at UTAwesome for that). My long term goal is to build a stroker G3 Hemi for the RamCharger and move the Magnum stroker to the TJ (while converting to an auto).

WOW great story.

I have EQ Monster heads with the 2.02 intake and 1.62 exhaust. My old engine in my TJ was a 5.2 that for some reason I could never get to run correctly which is what prompted me to get a 5.9. I was ALMOST done with a fairly budget rebuild on the 5.9 when a guy on one of the Dodge forums I'm on had posted that he was wanting to trade his 408 for a stock 360. Well we talked and he was wanting to swap complete engine for engine. But his top end was all stock and mine was all aftermarket so we agreed to do short blocks instead.

So the stroker I'm building has a Scat rotating assembly with HB hyper pistons. Along with the EQ heads I'm at 9.8:1 CR. And I got my cam from HiPotek and is a custom grind to pull as much torque as I can from the engine. It really hurt to tare that engine back down after all the work I'd put into it but I got a stroker for free and he even gave me the SCT tuner so I can get tune it.

I'm using FRP (Flyin Ryan Performance) for my tunes. The 6 pack into was just a crazy thought and will let that big engine breathe.

Keep us posted as you build your TJ & Ramcharger I'd like to hear about both of them. What is the build date on your TJ?

Date of Mfg: 11-97 per the door stickerKeep us posted as you build your TJ & Ramcharger I'd like to hear about both of them. What is the build date on your TJ?

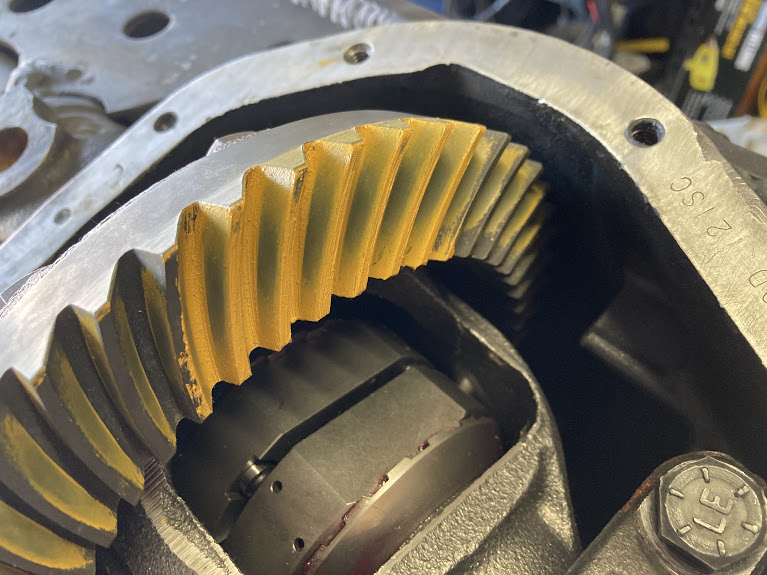

Spent the last half of the week suffering from allergies, but still managed to help a few buddies out. I got bud #1's Dana 30/Dana 44 combo regeared and rebuilt (new axle bearings, seals, etc.).

Then moved to my landscaper-turned-wheeling-buddy's D30HP (waiting on new thrust washers since his weren't the prettiest). Still have an F8.8 to build and then we can swap out (he also needs me to weld in some perches once it's out).

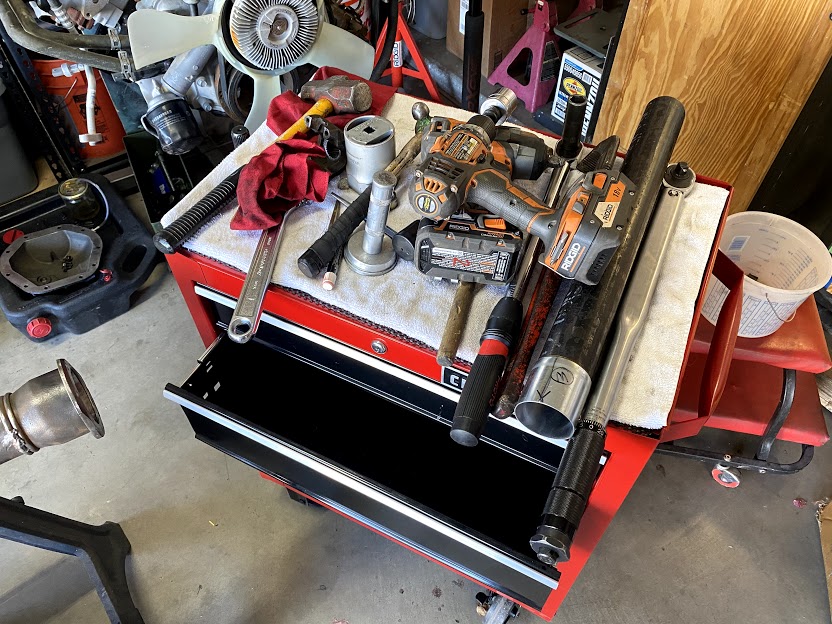

I bought a new Craftsman rolling toolbox, but as you can see with the piles of tools on the top and nothing in the drawers itself, it's sometimes a challenge to break old habits Once I realized I was using it as an expensive tabletop, I rearranged what was in the drawers to better accommodate wrenching (I still need to figure out some good cordless-tool hangers or hooks). I may move all my sockets and box wrenches into this drawer as well since it can easily roll around from project-to-project.

Once I realized I was using it as an expensive tabletop, I rearranged what was in the drawers to better accommodate wrenching (I still need to figure out some good cordless-tool hangers or hooks). I may move all my sockets and box wrenches into this drawer as well since it can easily roll around from project-to-project.

Then moved to my landscaper-turned-wheeling-buddy's D30HP (waiting on new thrust washers since his weren't the prettiest). Still have an F8.8 to build and then we can swap out (he also needs me to weld in some perches once it's out).

I bought a new Craftsman rolling toolbox, but as you can see with the piles of tools on the top and nothing in the drawers itself, it's sometimes a challenge to break old habits

In following the "Happy Spouse = Happy House" mantra, after wrapping up the axle work we got the house completely decorated for Christmas (my house looks like a Pier 1 catalog, my garage looks like a junkyard lol). The Mrs. and kids are happy (and I am too - the holidays are the best!) but I still snuck in some time for my projects early in the AM (thanks to Zyrtec!).

After pulling the harness off, I gave the Hemi a light soak and scrub. This is officially the cleanest motor I've ever built or worked on. None of the harness clips are cracked, the loom isn't brittle and there isn't a half-dozen mouse nests on the intake

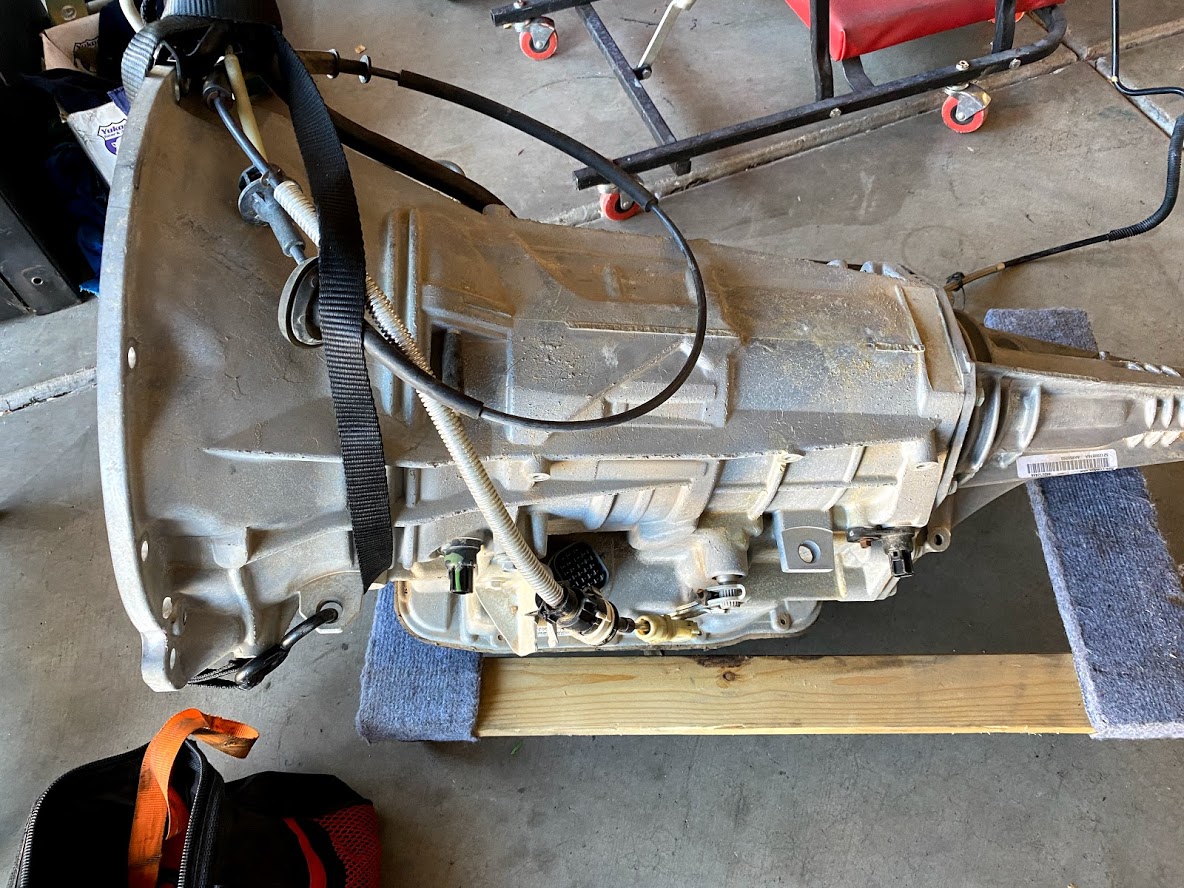

Looking at the Part #s and trying to decode this setup, I'm about 95% certain that this is a 2012 Hemi/65RFE combo from a 2WD Ram Truck. This would be the Eagle head Hemi (which was obvious by valve covers anyways), with VVT and "Active Intake" which puts out an honest 390hp/407tq...

In doing some research and after talking to my friend who's become somewhat of a G3 Hemi expert lately, this was a "great score by any measure!". With a decent header and tune, 420hp isn't unheard of; a cam swap (if wanting to keep it NA) is relatively simple and good for 500hp. I also learned that the 65RFE is nothing more than a 545RFE transmission with some different calibrations to allow use of all 6 forward gears. On the outside, it's physically identical to the 545RFE, so that means both the 65RFE and 545RFE are easily converted from 2WD to 4WD configuration (they're considered "modular" transmissions) - with nothing more than a tailshaft housing swap.

I need to confirm, but it appears that the 545/65RFE with 4WD extension is only 27" total (the same length as the old 727 4WD - it's like Mopar WANTS people to swap these!). The AX15 by comparison is 24" with the bellhousing. There's a lot to figure out and a handful of threads on Hemi-swappin' a TJ that I need to get caught up on. The short term plan is to start acquiring the parts that i know for sure I need: a TJ automatic brake pedal set, a later-year PCI gauge cluster, a 65RFE 4WD extension housing, a set of Jeep SRT headers, a drive-by-wire pedal, etc. I'm also going to pull the intake and heads on this Hemi and make sure the cam bearings look good and will swap out the head gaskets as a precaution.

While I'm parts sourcing stuff for the swap, I have a bunch of other stuff to get done:

After pulling the harness off, I gave the Hemi a light soak and scrub. This is officially the cleanest motor I've ever built or worked on. None of the harness clips are cracked, the loom isn't brittle and there isn't a half-dozen mouse nests on the intake

Looking at the Part #s and trying to decode this setup, I'm about 95% certain that this is a 2012 Hemi/65RFE combo from a 2WD Ram Truck. This would be the Eagle head Hemi (which was obvious by valve covers anyways), with VVT and "Active Intake" which puts out an honest 390hp/407tq...

In doing some research and after talking to my friend who's become somewhat of a G3 Hemi expert lately, this was a "great score by any measure!". With a decent header and tune, 420hp isn't unheard of; a cam swap (if wanting to keep it NA) is relatively simple and good for 500hp. I also learned that the 65RFE is nothing more than a 545RFE transmission with some different calibrations to allow use of all 6 forward gears. On the outside, it's physically identical to the 545RFE, so that means both the 65RFE and 545RFE are easily converted from 2WD to 4WD configuration (they're considered "modular" transmissions) - with nothing more than a tailshaft housing swap.

I need to confirm, but it appears that the 545/65RFE with 4WD extension is only 27" total (the same length as the old 727 4WD - it's like Mopar WANTS people to swap these!). The AX15 by comparison is 24" with the bellhousing. There's a lot to figure out and a handful of threads on Hemi-swappin' a TJ that I need to get caught up on. The short term plan is to start acquiring the parts that i know for sure I need: a TJ automatic brake pedal set, a later-year PCI gauge cluster, a 65RFE 4WD extension housing, a set of Jeep SRT headers, a drive-by-wire pedal, etc. I'm also going to pull the intake and heads on this Hemi and make sure the cam bearings look good and will swap out the head gaskets as a precaution.

While I'm parts sourcing stuff for the swap, I have a bunch of other stuff to get done:

- Finish my rock light wiring and install

- Install the Tuffy storage drawer

- Finish fitting the hood and primer-coating

- Replace the carpet (can't decide between molded vinyl like my YJ or a BedRug)

- Body work - fixing the driver half-door dent and pulling the rear quarter panel dent

- New seats (going with Corbeau Moabs again)

- Paint

- And I should probably start thinking about cage options...

Last edited:

Getting ready for my first trail ride with the TJ tomorrow and knocking some stuff off the prep list...

I've been wanting to replace the steel cable for sometime but wanted to wait until it was damaged first. Well that was like 3 years ago and nothing new has happened, so I took the plunge and swapped it out ahead of time!

I removed my door panels some time ago so that I could clean the locks and rekey them alike (tailgate, half doors, full doors and ignition switch). I didn't want to wheel and get my knee all cut up on the inner panel, so I wanted to put the panels back on. I decided to give them a good scrub and fresh coat of Dupli-Color vinyl coating. This stuff is amazing - I've used it 3-4 times now and have been impressed every time.

I know the UHF stuff is all the rage lately, but I find that most people that have them don't know how to use them, they tend to fall out of the cup holder or off the seat at the worst times, and generally don't offer me any advantage. I'm a tad old-school and love a good, tuned CB. I had this Cobra micro-CB for sometime but never installed it. I decided to put the receiver module under the console and have it easily accessible - but easily removable.

I've been wanting to replace the steel cable for sometime but wanted to wait until it was damaged first. Well that was like 3 years ago and nothing new has happened, so I took the plunge and swapped it out ahead of time!

I removed my door panels some time ago so that I could clean the locks and rekey them alike (tailgate, half doors, full doors and ignition switch). I didn't want to wheel and get my knee all cut up on the inner panel, so I wanted to put the panels back on. I decided to give them a good scrub and fresh coat of Dupli-Color vinyl coating. This stuff is amazing - I've used it 3-4 times now and have been impressed every time.

I know the UHF stuff is all the rage lately, but I find that most people that have them don't know how to use them, they tend to fall out of the cup holder or off the seat at the worst times, and generally don't offer me any advantage. I'm a tad old-school and love a good, tuned CB. I had this Cobra micro-CB for sometime but never installed it. I decided to put the receiver module under the console and have it easily accessible - but easily removable.

Sunflower Mine Trail

Nov-21-2020

Had a great time wheeling with two new Jeepin' buddies. We decided to take my shakedown run at Sunflower Mine Trail since most of the other trails in the area were going to be packed or were closed due to fires. Overall the suspension worked great and steering was amazing...

I had a few snags though... First, about 1/3 the way down the river bottom, my front e-locker wires pulled out of the connector. I thought it was originally from flexing out, but it kept pulling out the wires even after a trailside fix and cutting the zip-tie off of the control arm. I suspect one of the anti-rotation tabs broke (an unfortunate issued with e-lockers) or perhaps the wire was getting too close to the ring-gear during activation.

I dragged the diff a bunch - I've run this trail 3 times before and never once have I got hung up and this time the river was almost completely dry. I think it's due to the fact that the suspension droops so much that it keeps the axles really close to the rocks. This trail is full of diff-grabbing rocks... I had to be winched off this one!

Got a boo-boo and tweaked the rocker panel a bit - I hope Santa got my Christmas list with sliders and Corbeau Moab seats on it

Same rock did this to the body mount...

The 3.5" RK springs ride very nice, though I'm still able to get enough flex out of the Rubicon Express Superflex arms to completely drop the springs out of the bucket. They're stable and the retainers kept them in place, so not much to worry about there.

On the other side, the tire clears the shock tower at full bump - thumbs up there!

With good clearance above the tire to the fender!

Nov-21-2020

Had a great time wheeling with two new Jeepin' buddies. We decided to take my shakedown run at Sunflower Mine Trail since most of the other trails in the area were going to be packed or were closed due to fires. Overall the suspension worked great and steering was amazing...

I had a few snags though... First, about 1/3 the way down the river bottom, my front e-locker wires pulled out of the connector. I thought it was originally from flexing out, but it kept pulling out the wires even after a trailside fix and cutting the zip-tie off of the control arm. I suspect one of the anti-rotation tabs broke (an unfortunate issued with e-lockers) or perhaps the wire was getting too close to the ring-gear during activation.

I dragged the diff a bunch - I've run this trail 3 times before and never once have I got hung up and this time the river was almost completely dry. I think it's due to the fact that the suspension droops so much that it keeps the axles really close to the rocks. This trail is full of diff-grabbing rocks... I had to be winched off this one!

Got a boo-boo and tweaked the rocker panel a bit - I hope Santa got my Christmas list with sliders and Corbeau Moab seats on it

Same rock did this to the body mount...

The 3.5" RK springs ride very nice, though I'm still able to get enough flex out of the Rubicon Express Superflex arms to completely drop the springs out of the bucket. They're stable and the retainers kept them in place, so not much to worry about there.

On the other side, the tire clears the shock tower at full bump - thumbs up there!

With good clearance above the tire to the fender!

I power washed all the dust and grime off the Jeep and checked everything underneath for any hidden issues that didn't come up on the trail and found a few...

Looks like the Rancho 5000x's "self-clearanced" a little. There doesn't appear to be any damage other than some paint rubbing off and a slight dent in both sides. Clayton does warn that "big body" shocks may rub, but I guess I didn't consider the RS5000x body to be "big body"...

Looks like the clamp on the Currie tie-rod must have slightly kissed the bottom of the ram and the mounting spot. Thankfully, I think the damage is superficial and is limited to just some paint loss. I tried to rotate the clamps down, but then remembered why they were facing that way anyways - the Currie steering is notched and the clamps are unable to rotate freely.

To remedy the issue, I removed the tie-rod end at the driver-side knuckle, loosened both clamps, rotated the entire tie-rod 180º so that the clamp bolts were on the bottom side of the tie-rod, then rotated the tie-rod end at the knuckle in 180º. This kept the overall length the same and the steering was still arrow straight (my pet peeves are squeaks/rattles and a steering wheel that isn't straight!).

Nothing else appears to have been damaged or have issues, so I'm guess my clearances are good for now. With that, I turned to the front differential and to see if I can figure out this e-locker problem.

As I suspected, the retaining tabs both broke off and were at the bottom of the diff. Luckily I don't see any ring gear damage! I sent some photos to the vendor for this (East Coast Gear Supply - where I get almost all my axle stuff from!) and will see if I can warranty swap this out. I'm not super excited about pulling the Dana 30 apart again, but such is life...

While the parts are on their way, I will tackle some other items. It's time to get the hood fully welded up and sanded smooth (plus some primer before it starts rusting!). The damn prop rod has gone through 2 clips already and keeps falling down. I've about had enough and may order the Rugged Ridge gas lift for it.

It probably wouldn't hurt to start some of the body work too - pulling the dents out of the tub and getting some mud on there. Hoping to score some holiday deals at Summit Racing, so I should be ordering the paint soon. I need to finalize what color I'm going to order - I'm stuck between 3 at the moment:

Black Cherry Pearl

Black Starburst Pearl:

Brilliant Black Metallic:

I'm leaning toward Starburst Pearl for what it's worth. It will closely match the factory color but is plenty cheap. The single-stage acrylic urethane will run me $75 for the gallon and two-stage is under $100. I realize that I'm going to beat on this thing fairly regularly, so a fancy paint job isn't necessary - just something to make it look halfway respectable going down the road and keep the elements at bay (especially after we move up north to snowy country).

Looks like the Rancho 5000x's "self-clearanced" a little. There doesn't appear to be any damage other than some paint rubbing off and a slight dent in both sides. Clayton does warn that "big body" shocks may rub, but I guess I didn't consider the RS5000x body to be "big body"...

Looks like the clamp on the Currie tie-rod must have slightly kissed the bottom of the ram and the mounting spot. Thankfully, I think the damage is superficial and is limited to just some paint loss. I tried to rotate the clamps down, but then remembered why they were facing that way anyways - the Currie steering is notched and the clamps are unable to rotate freely.

To remedy the issue, I removed the tie-rod end at the driver-side knuckle, loosened both clamps, rotated the entire tie-rod 180º so that the clamp bolts were on the bottom side of the tie-rod, then rotated the tie-rod end at the knuckle in 180º. This kept the overall length the same and the steering was still arrow straight (my pet peeves are squeaks/rattles and a steering wheel that isn't straight!).

Nothing else appears to have been damaged or have issues, so I'm guess my clearances are good for now. With that, I turned to the front differential and to see if I can figure out this e-locker problem.

As I suspected, the retaining tabs both broke off and were at the bottom of the diff. Luckily I don't see any ring gear damage! I sent some photos to the vendor for this (East Coast Gear Supply - where I get almost all my axle stuff from!) and will see if I can warranty swap this out. I'm not super excited about pulling the Dana 30 apart again, but such is life...

While the parts are on their way, I will tackle some other items. It's time to get the hood fully welded up and sanded smooth (plus some primer before it starts rusting!). The damn prop rod has gone through 2 clips already and keeps falling down. I've about had enough and may order the Rugged Ridge gas lift for it.

It probably wouldn't hurt to start some of the body work too - pulling the dents out of the tub and getting some mud on there. Hoping to score some holiday deals at Summit Racing, so I should be ordering the paint soon. I need to finalize what color I'm going to order - I'm stuck between 3 at the moment:

Black Cherry Pearl

Black Starburst Pearl:

Brilliant Black Metallic:

I'm leaning toward Starburst Pearl for what it's worth. It will closely match the factory color but is plenty cheap. The single-stage acrylic urethane will run me $75 for the gallon and two-stage is under $100. I realize that I'm going to beat on this thing fairly regularly, so a fancy paint job isn't necessary - just something to make it look halfway respectable going down the road and keep the elements at bay (especially after we move up north to snowy country).

Good news - Chase from East Coast Gear Supply reached out to Eaton and they're shipping me a new actuator! Not sure when it will arrive, especially with the holiday around the corner, but it's at least processing.

Found some other dings that makes me glad I took the time to add some skid protection!

Found some other dings that makes me glad I took the time to add some skid protection!

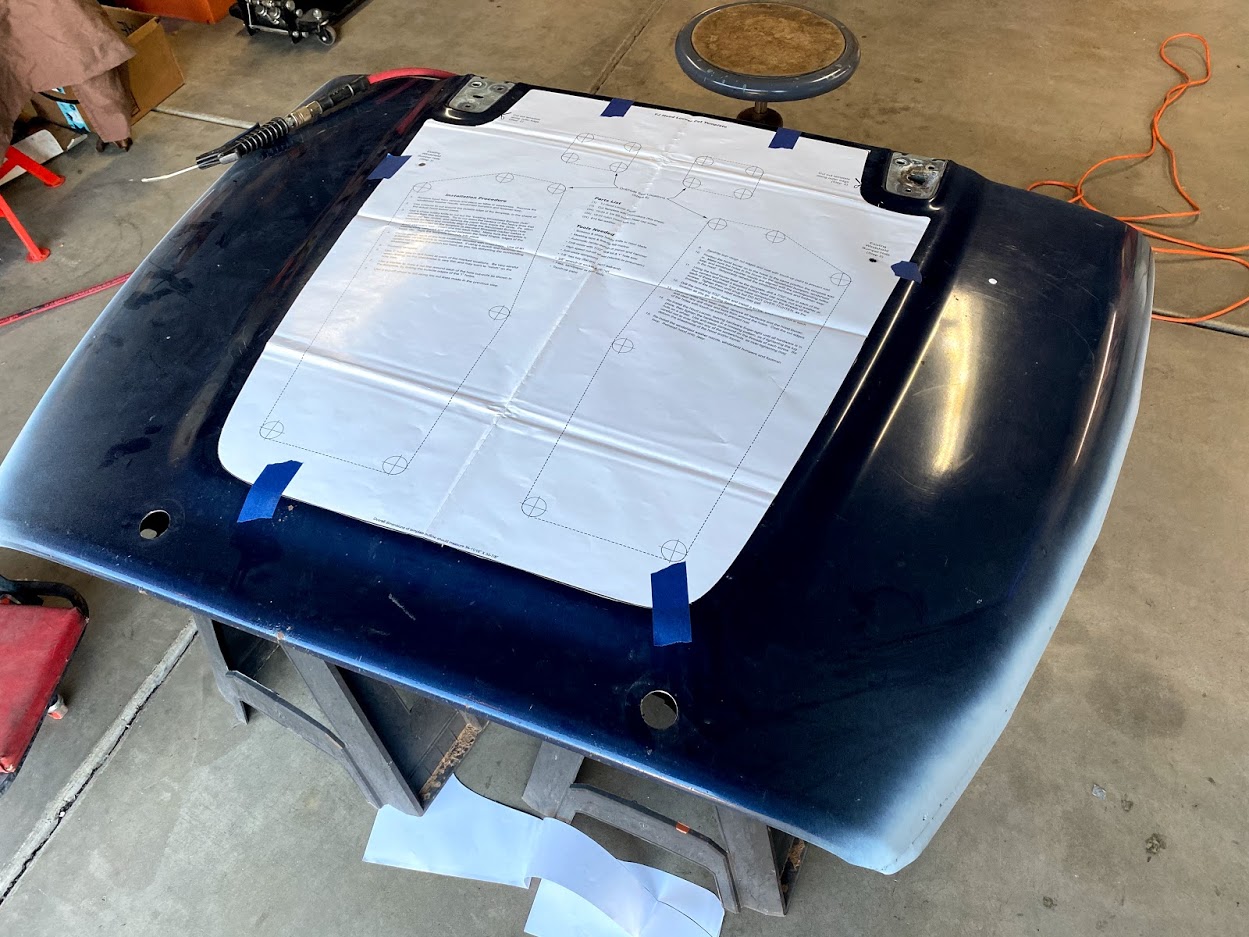

Well the body work isn't going to start by itself, so I figured it's time to get moving there...

First things first - get the hood trimmed for the louvers:

It was easy enough with a jigsaw and bi-metal cutting blade. I don't know if I'd want to try that with a hood where I was liking to keep the paint nice, but I suppose it can be done if you take your time and put down a few layers of masking tape.

There was a reason that I decided to cut out the panels first - I wanted to use the cut-outs for filler panels:

There were a few compound bends but the panel is thin and easily fitted. A couple of tack welds and work with a body hammer got a good fit! I wish I had a TIG welder - it's something definitely on my future shop list.

Oddly enough, I had better luck with 0.030' wire (vs 0.023") - I could crank down the voltage and jack up the wire speed a little to prevent blow-through, though there were plenty of spots along the way that caused me grief.

Once I was happy that I had enough spot welds holding everything together nicely, I put on a thin layer of mud. I sanded it down and was happy with the hold. I used my 5" DA which did a fairly reasonable job keeping the edges consistent and showing the low spots. After I had a nice clean edge, I put on another thin-coat to fill in the low spots and called it a day to fully harden up...

I hope to have it final sanded today, then I can work on the inside of the hood. I've already removed the VEIC label and VIN label (this hood isn't original to this Jeep) and then started doing some edge sanding and prep work. I will fill in the inner seams with seam-sealer and am thinking I'm going to use some low-expansion foam on the inner strut and rear brace. With the bottom portion of the hood cut away, I think it will add some needed stability and help with any vibrations/resonance that I hear can be a problem with hood louvers...

First things first - get the hood trimmed for the louvers:

It was easy enough with a jigsaw and bi-metal cutting blade. I don't know if I'd want to try that with a hood where I was liking to keep the paint nice, but I suppose it can be done if you take your time and put down a few layers of masking tape.

There was a reason that I decided to cut out the panels first - I wanted to use the cut-outs for filler panels:

There were a few compound bends but the panel is thin and easily fitted. A couple of tack welds and work with a body hammer got a good fit! I wish I had a TIG welder - it's something definitely on my future shop list.

Oddly enough, I had better luck with 0.030' wire (vs 0.023") - I could crank down the voltage and jack up the wire speed a little to prevent blow-through, though there were plenty of spots along the way that caused me grief.

Once I was happy that I had enough spot welds holding everything together nicely, I put on a thin layer of mud. I sanded it down and was happy with the hold. I used my 5" DA which did a fairly reasonable job keeping the edges consistent and showing the low spots. After I had a nice clean edge, I put on another thin-coat to fill in the low spots and called it a day to fully harden up...

I hope to have it final sanded today, then I can work on the inside of the hood. I've already removed the VEIC label and VIN label (this hood isn't original to this Jeep) and then started doing some edge sanding and prep work. I will fill in the inner seams with seam-sealer and am thinking I'm going to use some low-expansion foam on the inner strut and rear brace. With the bottom portion of the hood cut away, I think it will add some needed stability and help with any vibrations/resonance that I hear can be a problem with hood louvers...

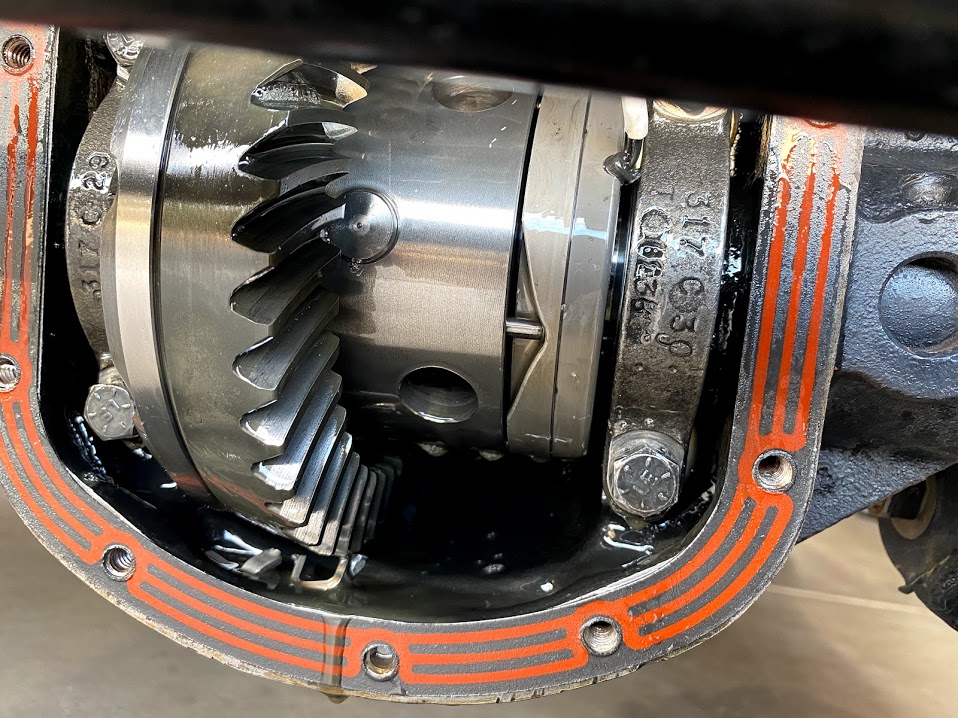

Spent a couple hours tackling the Dana 30 front locker that sheered the retaining tabs off...

I was worried about shipping delays - with the Thanksgiving holiday, holiday sales coming out, and the general laissez faire attitude of Eaton, my confidence wasn't high that I'd have the front end back together for @Chris upcoming trail ride down in Florence (Elvis Trail for the locals).

Much to my delight however, Eaton sent the replacements FedEx Priority Overnight and I had them just before the holiday break. Replacing the locker ring is simple, but does require removing the carrier bearing. Luckily, the Jegs bearing puller makes quick work of this, though it did chew up a few of the shims. Thankfully I had a stack of these e-locker specific shims handy (I think they're Dana 35 shims IIRC) and was able to duplicate the 0.062" stack and repressed the bearing back on.

After fighting the carrier back into place (it's much easier when I can use my case spreader!), I fought with the wiring grommet at the top of the case. I was eventually able to get it in the proper location with enough gear-lube specific RTV to be happy and then let it set overnight. After that, I repaired the plug, added the cover and LubeLocker, then topped off with some fresh Mopar GL5 synthetic gear lube. A test drive around the block showed good results and no leaks, then a quick test at the dirt powerline road showed the locker to be working as it should! I'm all good to go for this weekend

I was worried about shipping delays - with the Thanksgiving holiday, holiday sales coming out, and the general laissez faire attitude of Eaton, my confidence wasn't high that I'd have the front end back together for @Chris upcoming trail ride down in Florence (Elvis Trail for the locals).

Much to my delight however, Eaton sent the replacements FedEx Priority Overnight and I had them just before the holiday break. Replacing the locker ring is simple, but does require removing the carrier bearing. Luckily, the Jegs bearing puller makes quick work of this, though it did chew up a few of the shims. Thankfully I had a stack of these e-locker specific shims handy (I think they're Dana 35 shims IIRC) and was able to duplicate the 0.062" stack and repressed the bearing back on.

After fighting the carrier back into place (it's much easier when I can use my case spreader!), I fought with the wiring grommet at the top of the case. I was eventually able to get it in the proper location with enough gear-lube specific RTV to be happy and then let it set overnight. After that, I repaired the plug, added the cover and LubeLocker, then topped off with some fresh Mopar GL5 synthetic gear lube. A test drive around the block showed good results and no leaks, then a quick test at the dirt powerline road showed the locker to be working as it should! I'm all good to go for this weekend

Damn, you’re brave enough to install a locker yourself? I’ve always wanted to but I am afraid I’ll end up messing up the gear mesh pattern somehow as I’ve never done it before.

I do all my own stuntsDamn, you’re brave enough to install a locker yourself? I’ve always wanted to but I am afraid I’ll end up messing up the gear mesh pattern somehow as I’ve never done it before.

I do all my own stuntsI've regeared many axles, including all my Jeep and Dodge axles. I also do all my wiring and harness work, though I sometimes get some help with welding structural stuff since my 180A Lincoln struggles with 1/4" plate. It's not as hard as people think (it's actually quite simple) but does take some special tools and patience, plus it helps to have someone who knows what they're looking at to coach you along. I built a set of axles a few weekends ago (see earlier posts) for a bud and taught him the process.

I'll do all my own wiring work, but gears are one thing I am in fear of messing up. Too bad too, because I really want to throw in a set of Eaton E-Lockers this coming year.

I think like you said, it's not as hard as it's made out to be, it just takes special tools, patience, and someone who knows what they are doing overseeing you is a big plus as well.

Sure amAre you taking the TJ to Elvis this weekend?

Awesome. Can’t wait to see it run up and over!Sure am

If you want to do them in spring, I am available to help! I plan on taking the TJ down in a few weeks to begin the rest of the paint and Hemi swap, but should be done by end of Jan or early Feb. I will have time after that to swap a set of carrier. If you’re keeping the same ratio, we can simply refresh the bearings and seals. Wouldn’t be more than 4-5 hours with 2 people underneath...I'll do all my own wiring work, but gears are one thing I am in fear of messing up. Too bad too, because I really want to throw in a set of Eaton E-Lockers this coming year.

I think like you said, it's not as hard as it's made out to be, it just takes special tools, patience, and someone who knows what they are doing overseeing you is a big plus as well.

If you want to do them in spring, I am available to help! I plan on taking the TJ down in a few weeks to begin the rest of the paint and Hemi swap, but should be done by end of Jan or early Feb. I will have time after that to swap a set of carrier. If you’re keeping the same ratio, we can simply refresh the bearings and seals. Wouldn’t be more than 4-5 hours with 2 people underneath...

That would actually work out great timing wise. My plan was to do the lockers come spring, and I am just going to keep the existing 4.88 gears since I am happy with them. Like you said, new bearings and seals would be all I'd need other than the lockers.

4-5 hours wouldn't be bad at all, and I'd probably learn enough in the process that it would make me a lot more comfortable going forward