You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PC1P's 1998 Jeep TJ Build - "Ophelia"

- Thread starter pc1p

- Start date

Got the Jeep set in the garage where I wanted it and started stripping the parts off the rear - shocks, sway bar links, etc. and I disconnected and plugged the brake lines. I also pulled all the fuel and vent lines, as well as the brake line and locker wiring from the frame retaining clip.

I started marking the cut lines and making reference measurements around the frame and tub. Based on what I have seen on a number of TJ-6 builds that I've followed, I decided to follow their typical process of welding some 2" x 2" x 1/8" square stock to the frame on both sides of the cuts.

This does a few things:

- gives me good reference measurements on both sides of the frame (basically take the measured distance and the new measurements should be old + 5")

- prevents frame from twisting while cut

- can be used to support frame under jack stands/jack (especially when it come time to align them or lift back up!)

- can be used as a strap/clamp point to pull the two halves together

I only had a chance to get the one side welded up and hope to get the other 2x2" welded up this evening. Other than that, the only remaining tasks are to ever so slightly loosen the body mounts, pull the rear axle, and make the cuts!

I started marking the cut lines and making reference measurements around the frame and tub. Based on what I have seen on a number of TJ-6 builds that I've followed, I decided to follow their typical process of welding some 2" x 2" x 1/8" square stock to the frame on both sides of the cuts.

This does a few things:

- gives me good reference measurements on both sides of the frame (basically take the measured distance and the new measurements should be old + 5")

- prevents frame from twisting while cut

- can be used to support frame under jack stands/jack (especially when it come time to align them or lift back up!)

- can be used as a strap/clamp point to pull the two halves together

I only had a chance to get the one side welded up and hope to get the other 2x2" welded up this evening. Other than that, the only remaining tasks are to ever so slightly loosen the body mounts, pull the rear axle, and make the cuts!

Last edited:

Just from this last post or all of them?For some reason I can't see your pictures they just show up with a...

Just from this last post or all of them?

Just the last post. Sorry should have said that.

Well that was easier than I expected...

I did a test cut to see how much of a PITA the task was going to be and much to my surprised, even the cheap "Bauer" (aka HF) blades that I got for free on my last visit cut through with remarkable ease. The slice above took all of 30 seconds and that was because I was taking my time to make sure it was perfectly on the cut-line.

After double, triple and then quadruple checking to make sure I didn't do something stupid and that my bracing/stands were in a good place, I made the rest of the cuts. I used the straight cut on the front to act as my guide for the top and bottom cuts, and then also as the guide for the rear of the frame (cutting from the front). I used a small amount of cutting oil on the blade and it went through like butter!

Once cut, the frame and body only shifted maybe 1/32" of an inch, something I took as a good sign! I removed the body mounts and supported the rear on a pair of pipe stands while I used my jack in the center of the 2" x 2" square tube I welded across the frame yesterday. I lowered everything down slowly, a few inches at a time, until it was on the ground...

Motobilt says my crossmember and tank won't ship until Wednesday, which is disappointing since I don't think it will arrive at my house this before this weekend. I was hoping to use it to mock up the crossmember positions and tack them in place. Totten Tubes said my tube should have arrived on yesterday (Monday) evening's truck, which they said they will have cut and ready for me by Wednesday. Good news is that the 12' stick that I had to buy will be cut into three-pieces (4' sections) and I already have the other spare pieces sold to others who are also going to stretch their frames.

While I'm waiting on parts to arrive, I'm going to cut the inner crossmember off the frame and prep it. I'm thinking I'm going to cut the shock-mount portion of the crossmember off since there is no need for them and not having them there is one less thing for stuff to hit!

I did a test cut to see how much of a PITA the task was going to be and much to my surprised, even the cheap "Bauer" (aka HF) blades that I got for free on my last visit cut through with remarkable ease. The slice above took all of 30 seconds and that was because I was taking my time to make sure it was perfectly on the cut-line.

After double, triple and then quadruple checking to make sure I didn't do something stupid and that my bracing/stands were in a good place, I made the rest of the cuts. I used the straight cut on the front to act as my guide for the top and bottom cuts, and then also as the guide for the rear of the frame (cutting from the front). I used a small amount of cutting oil on the blade and it went through like butter!

Once cut, the frame and body only shifted maybe 1/32" of an inch, something I took as a good sign! I removed the body mounts and supported the rear on a pair of pipe stands while I used my jack in the center of the 2" x 2" square tube I welded across the frame yesterday. I lowered everything down slowly, a few inches at a time, until it was on the ground...

Motobilt says my crossmember and tank won't ship until Wednesday, which is disappointing since I don't think it will arrive at my house this before this weekend. I was hoping to use it to mock up the crossmember positions and tack them in place. Totten Tubes said my tube should have arrived on yesterday (Monday) evening's truck, which they said they will have cut and ready for me by Wednesday. Good news is that the 12' stick that I had to buy will be cut into three-pieces (4' sections) and I already have the other spare pieces sold to others who are also going to stretch their frames.

While I'm waiting on parts to arrive, I'm going to cut the inner crossmember off the frame and prep it. I'm thinking I'm going to cut the shock-mount portion of the crossmember off since there is no need for them and not having them there is one less thing for stuff to hit!

Nice cuts man! I’m going to hire you for all my future precision cuttingWell that was easier than I expected...

View attachment 234801

I did a test cut to see how much of a PITA the task was going to be and much to my surprised, even the cheap "Bauer" (aka HF) blades that I got for free on my last visit cut through with remarkable ease. The slice above took all of 30 seconds and that was because I was taking my time to make sure it was perfectly on the cut-line.

View attachment 234804

After double, triple and then quadruple checking to make sure I didn't do something stupid and that my bracing/stands were in a good place, I made the rest of the cuts. I used the straight cut on the front to act as my guide for the top and bottom cuts, and then also as the guide for the rear of the frame (cutting from the front). I used a small amount of cutting oil on the blade and it went through like butter!

Once cut, the frame and body only shifted maybe 1/32" of an inch, something I took as a good sign! I removed the body mounts and supported the rear on a pair of pipe stands while I used my jack in the center of the 2" x 2" square tube I welded across the frame yesterday. I lowered everything down slowly, a few inches at a time, until it was on the ground...

Motobilt says my crossmember and tank won't ship until Wednesday, which is disappointing since I don't think it will arrive at my house this before this weekend. I was hoping to use it to mock up the crossmember positions and tack them in place. Totten Tubes said my tube should have arrived on yesterday (Monday) evening's truck, which they said they will have cut and ready for me by Wednesday. Good news is that the 12' stick that I had to buy will be cut into three-pieces (4' sections) and I already have the other spare pieces sold to others who are also going to stretch their frames.

While I'm waiting on parts to arrive, I'm going to cut the inner crossmember off the frame and prep it. I'm thinking I'm going to cut the shock-mount portion of the crossmember off since there is no need for them and not having them there is one less thing for stuff to hit!

If I can use a square and silver-pen, then cut it straight with a $1.59 blade, I'm going to imagine a half-blind monkey could do it just as well (though deep down inside I know the monkey could probably do it slightly better!)Nice cuts man! I’m going to hire you for all my future precision cutting

God Damn half blind fucking monkey's manIf I can use a square and silver-pen, then cut it straight with a $1.59 blade, I'm going to imagine a half-blind monkey could do it just as well (though deep down inside I know the monkey could probably do it slightly better!)

Your cut is a little more forward of where I cut mine at. My cut was about even with the rear most body mount. You'll need to wait until you have the Savvy brackets to weld on the raised body mounts becasue the brackets need to be in place first.

It looks REALLY GOOD.

I must of been a totally blind fucking monkey cause I screwed up my cuts.....

But I can't seem to cut a straight line to save my life.

It looks REALLY GOOD.

I must of been a totally blind fucking monkey cause I screwed up my cuts.....

But I can't seem to cut a straight line to save my life.

What's your ETA for this thing to be up-and-running by at this point?

Based on the 5" frame extension with 3" of 1/8" sticking out each end, I put my cut where I had slightly over 3" of "free" space forward of the cut (with plenty behind). This is where most of the TJ-6 guys make the cut and I know they have had good success with this location, so I duplicated it. Seems like there are a few ways to skin the cat here??Your cut is a little more forward of where I cut mine at. My cut was about even with the rear most body mount. You'll need to wait until you have the Savvy brackets to weld on the raised body mounts becasue the brackets need to be in place first.

It looks REALLY GOOD.

What do you mean the body mount bracket can't be welded until the Savvy bracket is in place?

The Savvy mid-arm bracket and link kit is on backorder; I need to message them again to see if they have a timeline for shipment. My plan at this point in time it to get the frame extensions welded in place with the body installed, while getting the crossmembers welded (or mostly welded) in place. Once done, I will get the axle and suspension set back underneath and get the rig off of the jack stands.

Most of the TJ-6 guys fishplate the outside and inside (around the suspension mounts if applicable) of the frame rails. I saw that Blaine doesn't typically fishplate the outside of his, so I'm not sure if I'm going to or not. I won't be able to complete the inside fishplate until the tub is off and I have the Savvy mounts in hand, is that what you're talking about??

Once the Jeep is back on her tires, I will then cut off the center body mounts and replace with the GenRight ones (just tacked in place). This will let me get the tub pulled, which will allow me to do the final weldment of the crossmembers and body mounts - and should make the placement/weldment of the Savvy brackets much easier.

Mine still needs to be squared up a tad, but nothing major thankfully! If I were to do it again, I would use a thicker-kerf blade. I think it distorted ever so slightly on the driver-side cut towards the bottom and a thicker kerf would (in theory) stay a tad more true.I must of been a totally blind fucking monkey cause I screwed up my cuts.....

But I can't seem to cut a straight line to save my life.

Good question - here's my roughly-updated timeline:What's your ETA for this thing to be up-and-running by at this point?

March: finish stretch, replace body mounts, pull tub, begin paint prep

April: finish paint, complete Savvy/suspension work

May: put tub back on, HVAC box rebuild, reassemble front end, wire engine, install exhaust

June: gauges, beta test motor/trans around street, make any tweaks as needed

July: put a few hundred miles each week on motor, install A/C, try to get factory cruise working

Aug: BedRug flooring, new seats, interior work; depending on weather, hit up a moderate trail

Sept: go nuts!

Since we have delayed our move and I was able to tackle the stretch and suspension, I am now planning on being back on the trails in Aug/Sept. I expect to be done and back on the road in June, but I'm sure as hell am not going to do my shakedown runs in the peak heat of the summer! I will use June/July to do some rides around town, get my A/C working, see if I can figure out the OEM cruise and get it to work with the Hemi ECM, etc. I'll also use this time to get my flooring done and find some new seats.

In the short term, once I get the tub off, my focus will be on getting it prepped and painted. With summer around the corner, I need to make it a priority, otherwise it will significantly slow me down since paint won't happen until Sept/Oct! My plan is to push the frame out to the side yard and cover it well, which will give me the entire garage to work on the tub, armor, fenders, hood, etc. It shouldn't take me too long to get it all prepped and painted - I'm planning on 2 weeks total (with 2 weekends worth of work).

Once everything is painted, the tub can be moved to either the one side of the garage or to the side yard and I'll park it under a large pop-up tent to keep the sun and elements off of it, while allowing the paint to fully cure and harden. I expect to have the stretch and Savvy/suspension stuff done by end of April (depending on if Savvy can ship these in a reasonable amount of time), which will let me get the freshly-painted tub back on the frame just before the summer heat begins to fully kick in. I have already prepped the wiring harnesses and they're ready to go for the Hemi swap. I will just need to hook them all up, wrap the wire in fresh loom, and then fully get the front completed. ETA there is end of May...

The raised body mounts go in the same place that the front body mounts go and depending on where you set the rear brackets the rear body mount will hit where the rear brackets are also. So depending on how the mounts sit on the frame you MIGHT have to trim the body mounts a little to make them sit properly.

I have the SWAG body mounts but haven't installed them yet and haven't fully welded the Savvy brackets on yet either. I've got to finish up my front stretch and then I can move on to all the welding that I need to do.

I have the SWAG body mounts but haven't installed them yet and haven't fully welded the Savvy brackets on yet either. I've got to finish up my front stretch and then I can move on to all the welding that I need to do.

Good to know - I assume the Savvy mounts completely "C" the frame from the inside? I haven't seen them in person yet so I was just assuming they mounted on inside face and bottom face. I will put the rear mount in place but just tack it in - good tipThe raised body mounts go in the same place that the front body mounts go and depending on where you set the rear brackets the rear body mount will hit where the rear brackets are also. So depending on how the mounts sit on the frame you MIGHT have to trim the body mounts a little to make them sit properly.

I have the SWAG body mounts but haven't installed them yet and haven't fully welded the Savvy brackets on yet either. I've got to finish up my front stretch and then I can move on to all the welding that I need to do.

Thanks for that! I didn't realize that - that be a PITA to have to cut off and redo... Maybe I'll just leave the front and rear mount off all together and then just do those AFTER the Savvy brackets...I'll snap a few pictures for you but yes the brackets completely "C" the frame so the front & rear body mounts sit just about where the Savvy brackets are also.

I sent Savvy a message too to see when they expect the MUA kit in stock, hopefully it's soon!

Okay now you have me wondering if it would be better to simply notch the Savvy bracket around the GenRight body mount or the other way around... It wouldn't be too particularly hard to cut 1/4" off (or whatever the thickness of the Savvy brackets are) off the portion that touches the top of the frame. This would sit on top of the Savvy bracketsOK here is the passenger front bracket.

And then the rear passenger bracket.

So the body mounts will be in the same area.

I called Totten Tubes (https://www.tottentubes.com/) today and they said that the tube has been cut and bundled (I had the 12' stick I had to buy cut into 3 pieces for easy transport in the Grand Cherokee!) and is ready for pick-up!  With any luck, the new cobalt 1/2" drill bits will also arrive today and I can start prepping the stretch pieces...

With any luck, the new cobalt 1/2" drill bits will also arrive today and I can start prepping the stretch pieces...

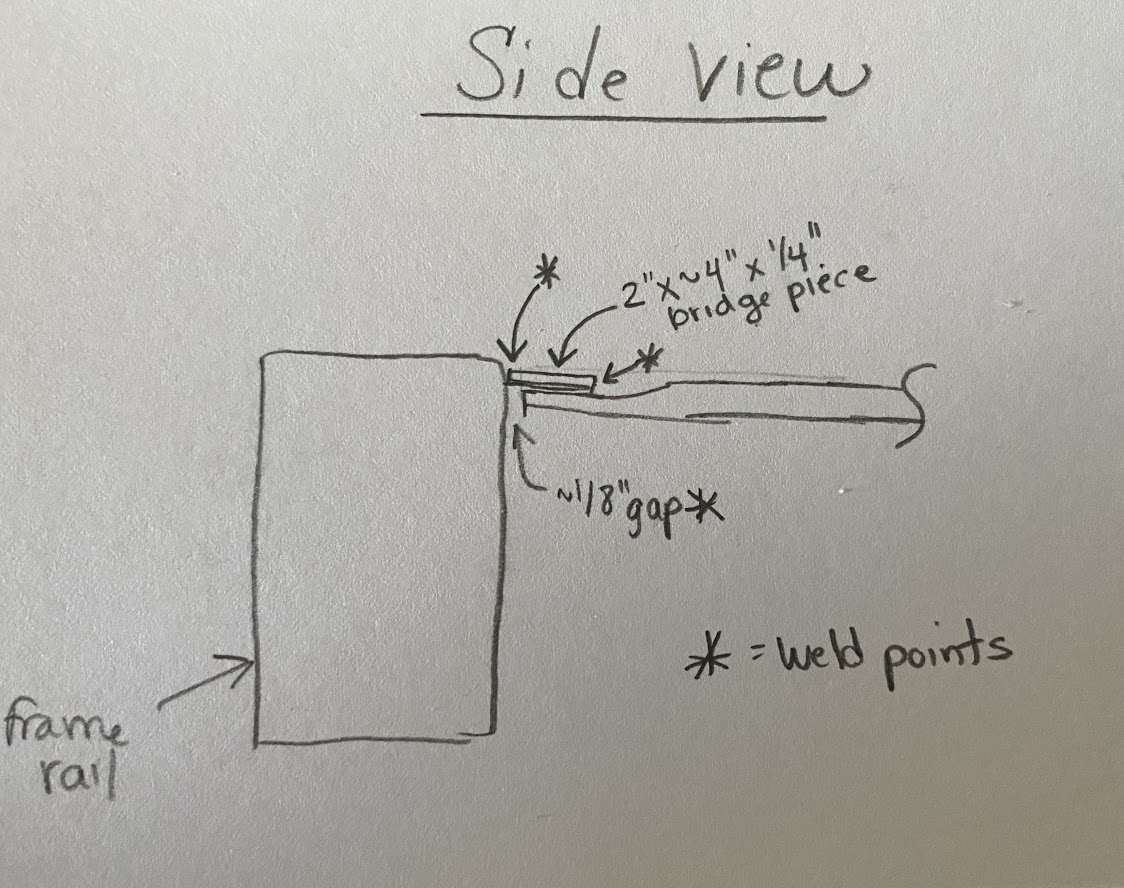

After a little bit of angle grinder and sawzall action, I got the middle crossmember cut out. I kept the blade super tight to the frame the entire time so there wasn't much to grind away from the rail, but there is still a somewhat measureable gap to be closed up. Rather than goop a bunch of weld in there, I'm thinking of making a small bridge plate out of some 1/4" flat stock. Something like this...

I'm going to cut off the "wings" from the crossmember that the shocks mount to this afternoon and make those bridge pieces... the goal is to get the frame stretch and welded in place on Saturday!

After a little bit of angle grinder and sawzall action, I got the middle crossmember cut out. I kept the blade super tight to the frame the entire time so there wasn't much to grind away from the rail, but there is still a somewhat measureable gap to be closed up. Rather than goop a bunch of weld in there, I'm thinking of making a small bridge plate out of some 1/4" flat stock. Something like this...

I'm going to cut off the "wings" from the crossmember that the shocks mount to this afternoon and make those bridge pieces... the goal is to get the frame stretch and welded in place on Saturday!