I just completed the regearing of my Rubicon from the miserable 4.88's to 5.38 and wow, what a nice improvement in its overall performance.

My TJ never performed well with its 4.88 gears with 35” tires and the 42RLE 4-speed automatic transmission. The problem being the transmission’s overly steep .69 Overdrive ratio that lowers the highway engine RPMs too much. The engine was always either lugging or on the verge of lugging on the freeway with 4.88 gears. While livable, it was a pig of a combination. Neither the engine nor the transmission was happy cruising on the highway with that combination.

5.13 gearing was attractive but there wasn’t enough difference between it and 4.88 to get serious. What finally convinced me it was time to regear was when Revolution Gear introduced 5.38 gears for the Rubicon’s Dana 44 axles. No one else is making 5.38's for the TJ Rubicon, RGA is the only game in town.

I was stoked when these boxes showed up on my porch.

Note the ‘Thick’ ring gear designation on the label. That means they fit and work with the Rubicon lockers made to work with higher (lower number) ratios. A conventional non-thick 5.38 ring gear will not work with the TJ Rubicon lockers.

Never having regeared an axle before today, an experienced friend, Jody Self, offered his assistance. Thank you Jody! This was a driveway regear job, no fancy shop is needed.

The only specialized tools required include a press for the new bearings, bearing puller, dial indicator for the backlash setting, a ½” torque wrench, and an inch-lbs. beam-style ¼” torque wrench for setting the pinion bearing preload.

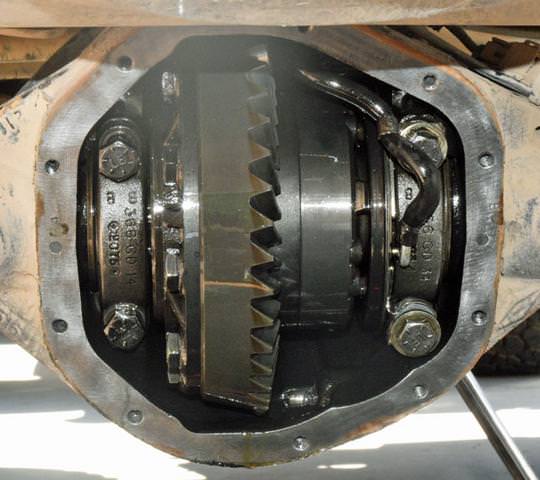

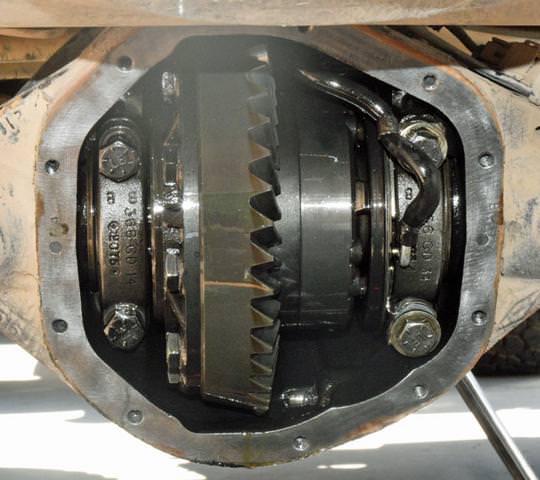

For those who have never seen under your differential cover, here you go. That rubber hose on the right is for the Rubicon’s air locker.

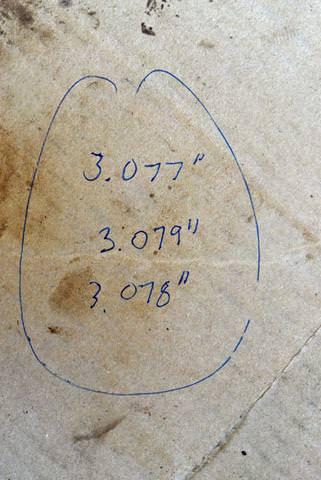

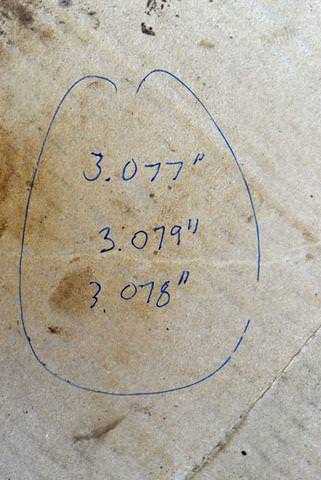

After removing the carrier, the existing pinion gear depth was measured using the bearing cap seating surface as a reference point. That gave a very good preliminary depth from which to set the new pinion gear depth. Setting the pinion gear depth involves shimming it in/out with shims included in the master install kit.

This shows initial pinion depth measurements, we’re measuring down to the thousandth of an inch.

It requires a bearing puller to pull the carrier and pinion bearings off. The bearings have a TIGHT fit so they require a bearing puller powered by an impact wrench. It takes a while for the bearing to finally come off even with this setup.

This is the master install kit which includes everything needed… pinion and carrier bearings, ring gear bolts, pinion seal, shims, gear marking compound, pinion nut, and Loctite for the new ring gear bolts.

The empty housing.

Installing the ring gear requires Loctite be applied to the new ring gear bolts. That prevents the bolts from backing out which can destroy pretty much everything inside the housing. Some use blue Loctite but we used red which is more secure. Revolution's ring gear fit over the Rubicon locker snugly/perfectly without needing to heat the ring gear and freeze the locker/carrier as some require.

Pressing the pinion bearings.

Reinstalling the Rubicon locker reuses the Rubicon's OE carrier shims to position it left/right to create the right amount of backlash between the gears. Too little backlash between them can cause insufficient lubrication between the gears and damage the tooth surfaces, too much backlash reduces strength. We ended up with the backlash being right on at .008, same as it was originally.

This pic shows using a brass punch to tap in the shim. Using brass here eliminates damage to the shim. Just be careful you get the same shims back in the same sides they came out of.

Painting the gear marking compound onto the gear teeth.

The initial test pattern was nearly perfect and "good enough" but adding .002 would make it perfect so that's what was done.

Part of the setup procedure requires setting the pinion bearing preload which requires a small 1/4" drive in-lbs. bar-indicator torque wrench. Revolution specifies between 14 and 19 inch-lbs. of resistance required to rotate the pinion gear. We ended up right at 18 inch-lbs.

Checking the final backlash between the gears. Revolution Gear specified .006 to .010, we ended up at .008.

One thing about the Rubicon’s locker and sensor, you have to pay attention to getting the carrier and sensor situated correctly together. With help from Brook at RGA and danb303 and TJR238 here on JF, I used the “toothpick” technique to fully extend the sensor's pin out far enough to clear and avoid damage while inserting the locker back into the housing.

Once the locker is back in place after the final pattern and preload adjustments have been completed, you pull the toothpick out with the fishing line tied to it. That releases the sensor to seat properly behind the locker’s actuator plate. However, this is only a concern if you have a Rubicon.

With that we buttoned the axles up and I’ve been busy breaking the new gears in per RGA’s break-in procedure. I’m now at the point I can cruise at highway speeds with an upcoming change at 500 miles from the break-in conventional 85w-140 gear lube to the final conventional 85W-140 as recommended by Revolution Gear. Be sure to only use a conventional gear lube here as specified by Revolution. Use of a synthetic here can and will cause accelerated gear wear.

All in all, getting the patterns perfect was easier than expected. We really only had one iteration of shimming so on the second shim combination, Jody pronounced the pattern perfect on both the drive and coast side of the gears.

Driving it has been a joy with the new higher RPMs. At 70 mph, I’m now roughly 2600 RPMs and it’s hard to describe it but the engine is truly obviously running better. No lugging now with the 5.38 gearing, it’s now as close to perfect as can be with the Rubicon lockers which limit just how low the gearing can be. It's so cool having that new 5.38 ratio available now, what an improvement it made.

A big thanks to Brook at Revolution Gear and Jody Self for all your help! www.revolutiongear.com

My TJ never performed well with its 4.88 gears with 35” tires and the 42RLE 4-speed automatic transmission. The problem being the transmission’s overly steep .69 Overdrive ratio that lowers the highway engine RPMs too much. The engine was always either lugging or on the verge of lugging on the freeway with 4.88 gears. While livable, it was a pig of a combination. Neither the engine nor the transmission was happy cruising on the highway with that combination.

5.13 gearing was attractive but there wasn’t enough difference between it and 4.88 to get serious. What finally convinced me it was time to regear was when Revolution Gear introduced 5.38 gears for the Rubicon’s Dana 44 axles. No one else is making 5.38's for the TJ Rubicon, RGA is the only game in town.

I was stoked when these boxes showed up on my porch.

Note the ‘Thick’ ring gear designation on the label. That means they fit and work with the Rubicon lockers made to work with higher (lower number) ratios. A conventional non-thick 5.38 ring gear will not work with the TJ Rubicon lockers.

Never having regeared an axle before today, an experienced friend, Jody Self, offered his assistance. Thank you Jody! This was a driveway regear job, no fancy shop is needed.

The only specialized tools required include a press for the new bearings, bearing puller, dial indicator for the backlash setting, a ½” torque wrench, and an inch-lbs. beam-style ¼” torque wrench for setting the pinion bearing preload.

For those who have never seen under your differential cover, here you go. That rubber hose on the right is for the Rubicon’s air locker.

After removing the carrier, the existing pinion gear depth was measured using the bearing cap seating surface as a reference point. That gave a very good preliminary depth from which to set the new pinion gear depth. Setting the pinion gear depth involves shimming it in/out with shims included in the master install kit.

This shows initial pinion depth measurements, we’re measuring down to the thousandth of an inch.

It requires a bearing puller to pull the carrier and pinion bearings off. The bearings have a TIGHT fit so they require a bearing puller powered by an impact wrench. It takes a while for the bearing to finally come off even with this setup.

This is the master install kit which includes everything needed… pinion and carrier bearings, ring gear bolts, pinion seal, shims, gear marking compound, pinion nut, and Loctite for the new ring gear bolts.

The empty housing.

Installing the ring gear requires Loctite be applied to the new ring gear bolts. That prevents the bolts from backing out which can destroy pretty much everything inside the housing. Some use blue Loctite but we used red which is more secure. Revolution's ring gear fit over the Rubicon locker snugly/perfectly without needing to heat the ring gear and freeze the locker/carrier as some require.

Pressing the pinion bearings.

Reinstalling the Rubicon locker reuses the Rubicon's OE carrier shims to position it left/right to create the right amount of backlash between the gears. Too little backlash between them can cause insufficient lubrication between the gears and damage the tooth surfaces, too much backlash reduces strength. We ended up with the backlash being right on at .008, same as it was originally.

This pic shows using a brass punch to tap in the shim. Using brass here eliminates damage to the shim. Just be careful you get the same shims back in the same sides they came out of.

Painting the gear marking compound onto the gear teeth.

The initial test pattern was nearly perfect and "good enough" but adding .002 would make it perfect so that's what was done.

Part of the setup procedure requires setting the pinion bearing preload which requires a small 1/4" drive in-lbs. bar-indicator torque wrench. Revolution specifies between 14 and 19 inch-lbs. of resistance required to rotate the pinion gear. We ended up right at 18 inch-lbs.

Checking the final backlash between the gears. Revolution Gear specified .006 to .010, we ended up at .008.

One thing about the Rubicon’s locker and sensor, you have to pay attention to getting the carrier and sensor situated correctly together. With help from Brook at RGA and danb303 and TJR238 here on JF, I used the “toothpick” technique to fully extend the sensor's pin out far enough to clear and avoid damage while inserting the locker back into the housing.

Once the locker is back in place after the final pattern and preload adjustments have been completed, you pull the toothpick out with the fishing line tied to it. That releases the sensor to seat properly behind the locker’s actuator plate. However, this is only a concern if you have a Rubicon.

With that we buttoned the axles up and I’ve been busy breaking the new gears in per RGA’s break-in procedure. I’m now at the point I can cruise at highway speeds with an upcoming change at 500 miles from the break-in conventional 85w-140 gear lube to the final conventional 85W-140 as recommended by Revolution Gear. Be sure to only use a conventional gear lube here as specified by Revolution. Use of a synthetic here can and will cause accelerated gear wear.

All in all, getting the patterns perfect was easier than expected. We really only had one iteration of shimming so on the second shim combination, Jody pronounced the pattern perfect on both the drive and coast side of the gears.

Driving it has been a joy with the new higher RPMs. At 70 mph, I’m now roughly 2600 RPMs and it’s hard to describe it but the engine is truly obviously running better. No lugging now with the 5.38 gearing, it’s now as close to perfect as can be with the Rubicon lockers which limit just how low the gearing can be. It's so cool having that new 5.38 ratio available now, what an improvement it made.

A big thanks to Brook at Revolution Gear and Jody Self for all your help! www.revolutiongear.com

Last edited: