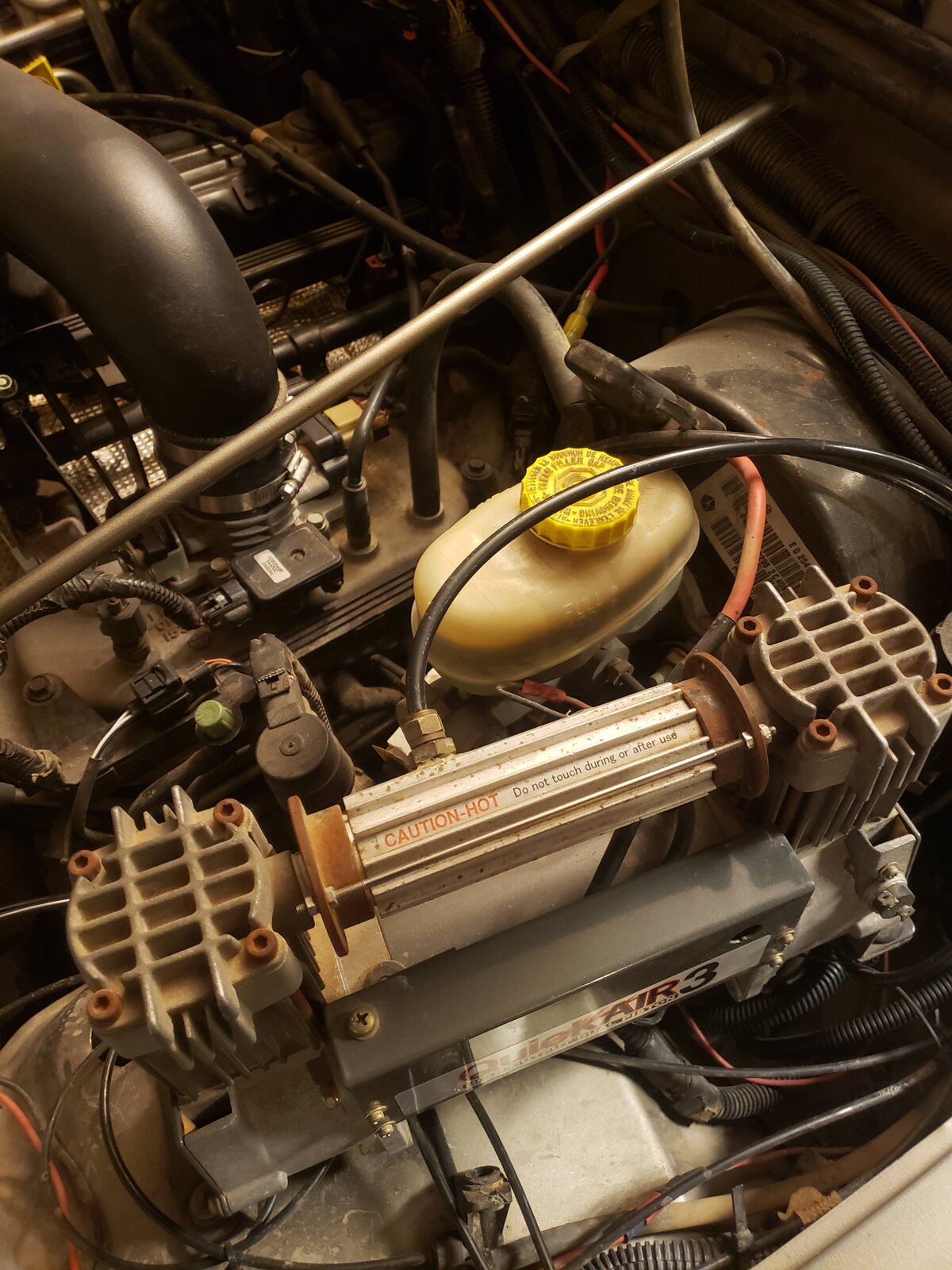

Think I'm ok running front and rear arb's and tank using this Quick Air 3 compressor?

The compressor is plumbed to a Viair 1 gal tank installed by p.o. it has been powering the front locker and external air chuck since I have owned. I know that the tank is essentially a manifold and serves no real storage purpose.

Think I can I tee right off the compressor with a line running to the tank to continue oba from tank and also piggyback two arb solenoids right off the other side of the tee to power both lockers?

I will eventually kick down for an arb compressor but have exhausted funds for now and have a few more things to dial in pre - Moab! Anyone successfully running something similar?

Looking for short term but serviceable. Thanks

The compressor is plumbed to a Viair 1 gal tank installed by p.o. it has been powering the front locker and external air chuck since I have owned. I know that the tank is essentially a manifold and serves no real storage purpose.

Think I can I tee right off the compressor with a line running to the tank to continue oba from tank and also piggyback two arb solenoids right off the other side of the tee to power both lockers?

I will eventually kick down for an arb compressor but have exhausted funds for now and have a few more things to dial in pre - Moab! Anyone successfully running something similar?

Looking for short term but serviceable. Thanks