I finally got around to replacing the multifunction switch. My fog lights were on permanently, and I had to pull the relay until I replaced the switch. But it was cold, and I had other stuff to do; so I procrastinated until today. Anyway, it’s now fixed, and the fog lights work correctly.

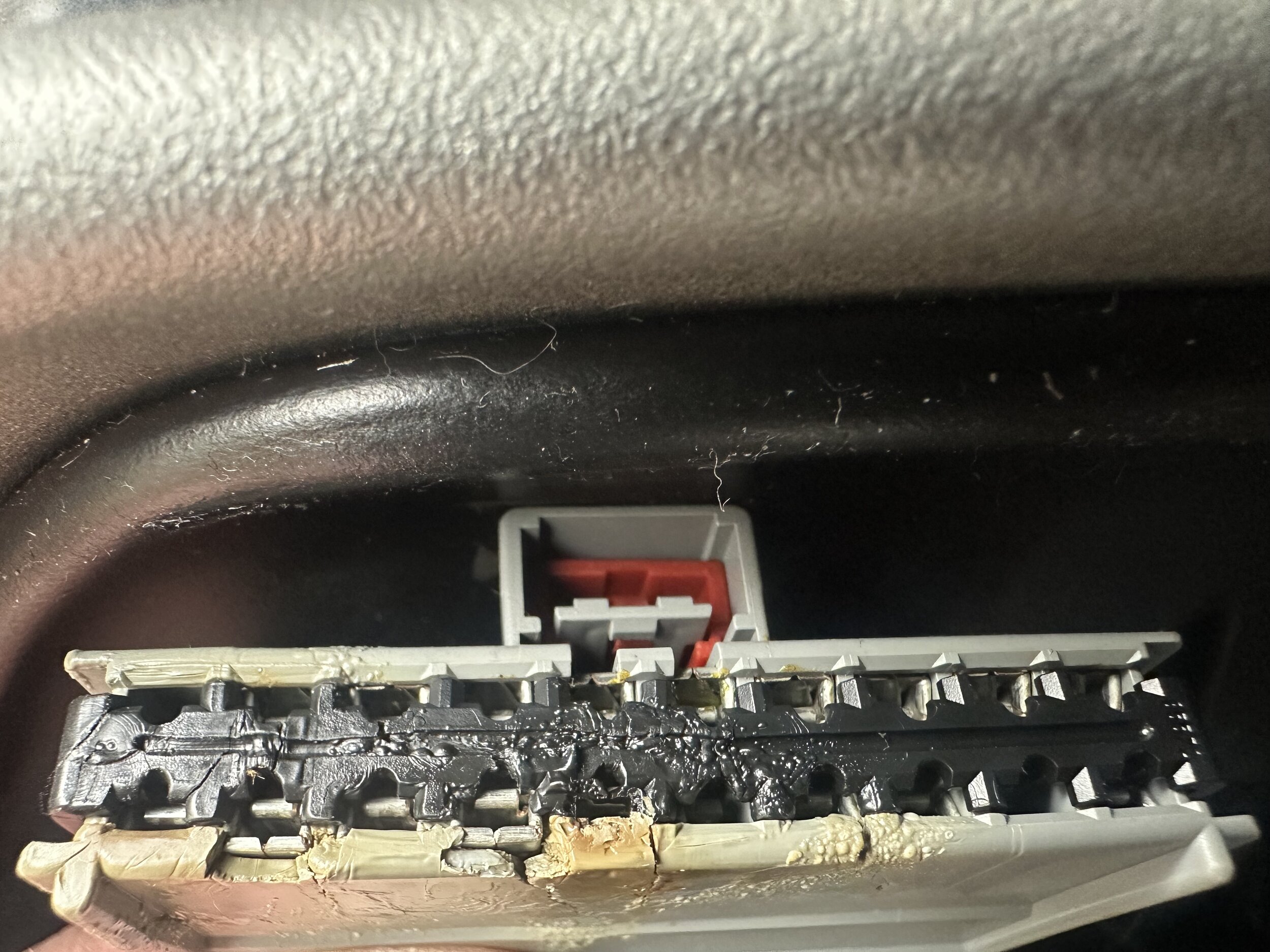

But when I pulled the main harness (the big one on top), it looked like this. Does it look a little, I don’t know, melted?

But when I pulled the main harness (the big one on top), it looked like this. Does it look a little, I don’t know, melted?