nope, it won't go back that far without some major trimming, and my piece is not worth the work. the CM has the orange cancer and i have new steel to replace it all and it'll be easier to just fab it with new materials.

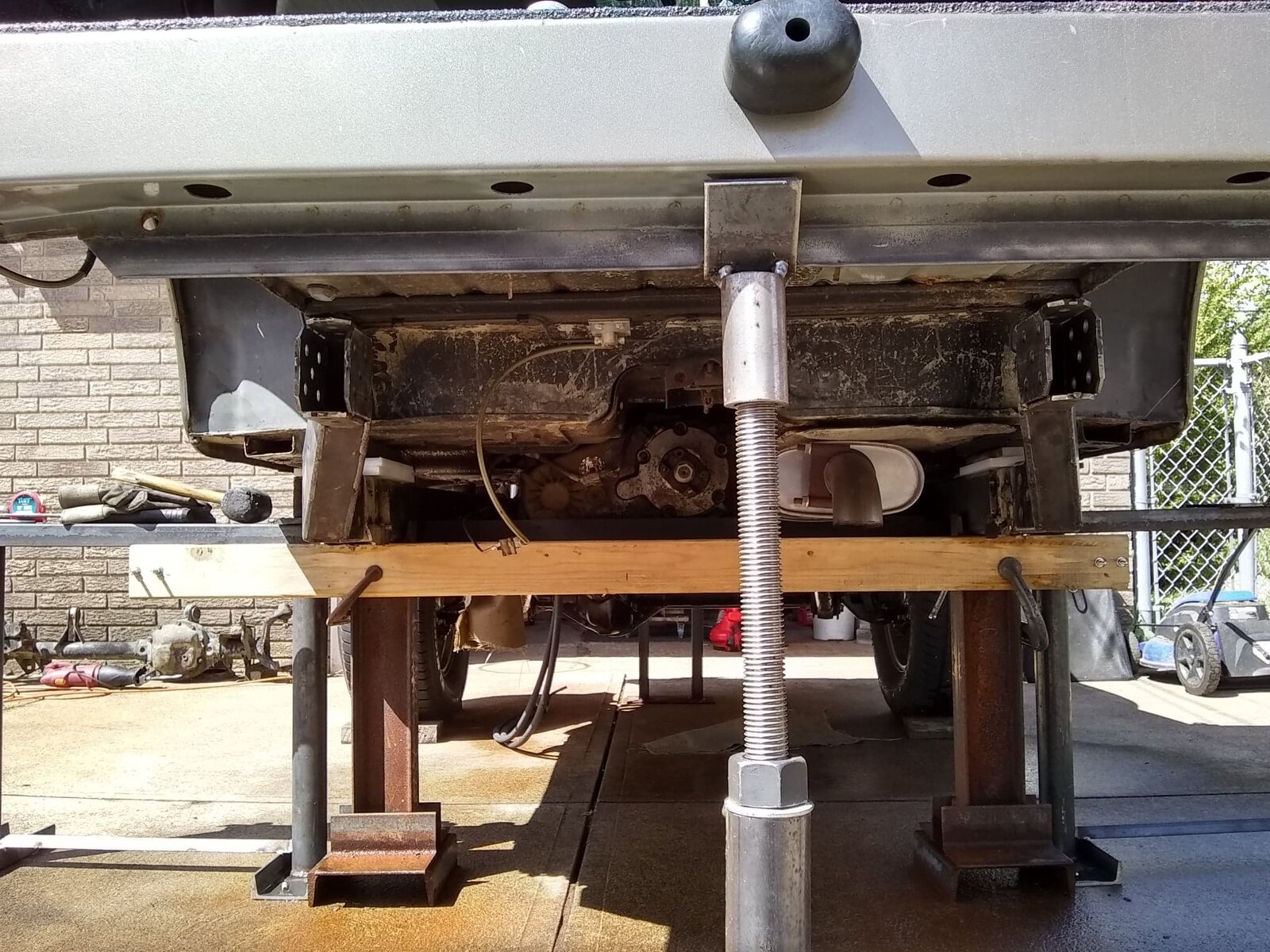

my new risers seem to fit right on the $. but b4 reconstruction begins i wanna wire whip the remaining frame tube and retreat it internally. i hosed it all out, best i could until i rig up a whip.

my new risers seem to fit right on the $. but b4 reconstruction begins i wanna wire whip the remaining frame tube and retreat it internally. i hosed it all out, best i could until i rig up a whip.