You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stretched TJK (bigger rubber & extra inches)

- Thread starter sierradmax

- Start date

Relocated leak detection pump and charcoal canister. Clears at full bump.

I enjoy checking in on your build. You take a different path, which is nice to see!

I enjoy checking in on your build. You take a different path, which is nice to see!

No Path is right or wrong. I just wish it were alot shorter.

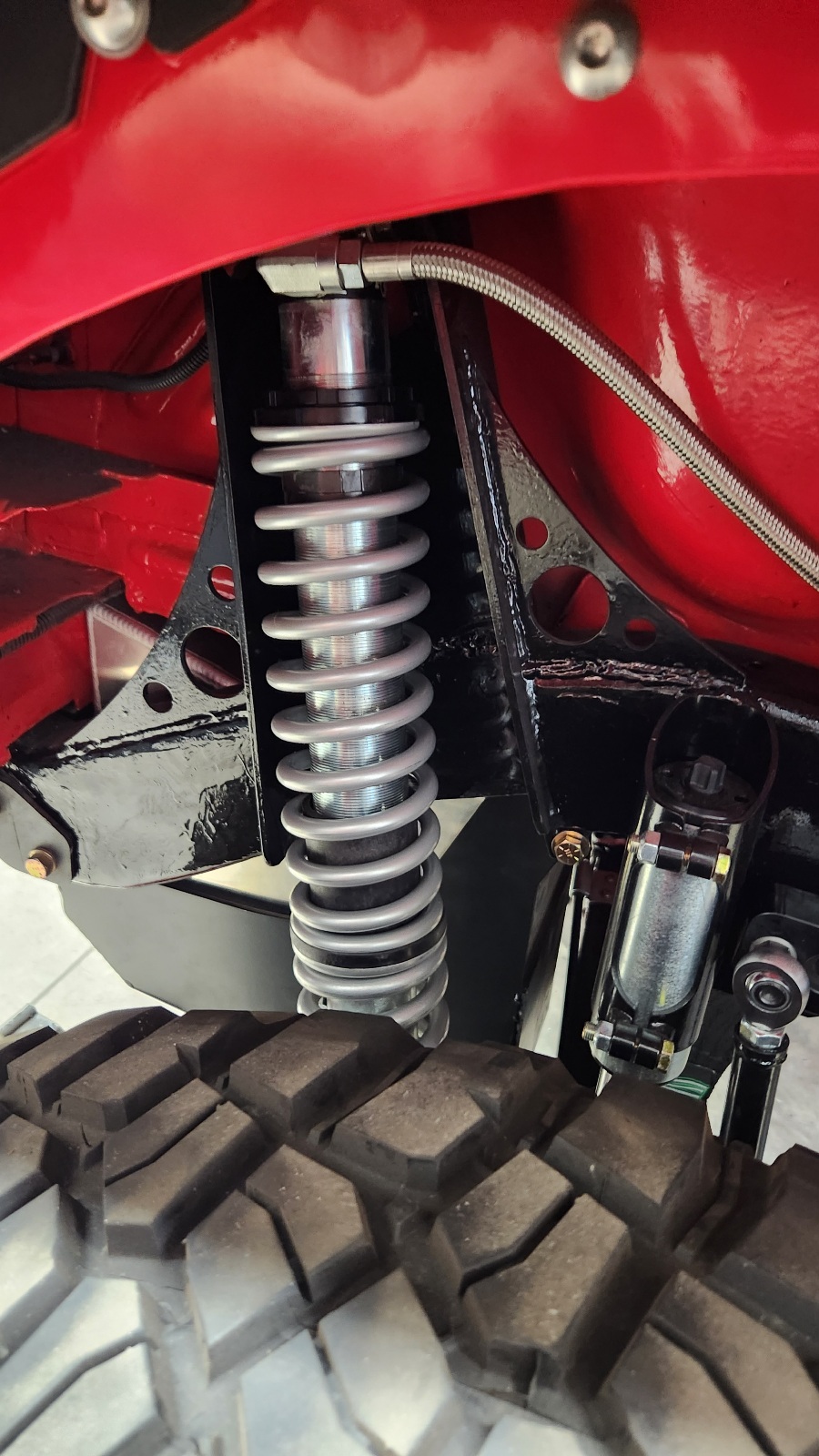

A couple weeks ago, I dropped the rig on all 4. Threw a tool bag in the back and told my wife I needed her 120 lbs. to also sit in the back. I don't plan on running a spare, at the moment. With some 16", 250 # coils, I adjusted the dual rate sliders to set the rig at desired ride height. Took shaft & coil spring measurements then called up Poly Performance. Additionally, I wanted the coilovers tuned. I could have gone with Accutune but here on the East Coast, we're an eclectic group. After speaking with several seasoned offroad veterans, I decided to send them to Chris Weygandt @ Diddy's Big Block Race Shop. His service was very professional, always took your call and did a few extra things (besides valving). We shall see how they perform. However, hopefully I got the rate & coil spring selection right on the first try.. If not, gotta thank Poly for coil spring swap exchange.

A couple weeks ago, I dropped the rig on all 4. Threw a tool bag in the back and told my wife I needed her 120 lbs. to also sit in the back. I don't plan on running a spare, at the moment. With some 16", 250 # coils, I adjusted the dual rate sliders to set the rig at desired ride height. Took shaft & coil spring measurements then called up Poly Performance. Additionally, I wanted the coilovers tuned. I could have gone with Accutune but here on the East Coast, we're an eclectic group. After speaking with several seasoned offroad veterans, I decided to send them to Chris Weygandt @ Diddy's Big Block Race Shop. His service was very professional, always took your call and did a few extra things (besides valving). We shall see how they perform. However, hopefully I got the rate & coil spring selection right on the first try.. If not, gotta thank Poly for coil spring swap exchange.

View attachment 449374

Damn that setup look familiar…

Nice work. Can’t wait to hear how the tune works out.

The light at the end of the tunnel is getting brighter.

- Finished running braided fuel line & evap hose.

- Wired the relocated evap leak detection pump.

- Installed Durango M/C with new hardlines to front/rear axle.

- Current Selection of coils will need new primary coil selection.

Front: 125 over 200. Sits about 1.5" too low. Going to try 150/200 then adjust for preload.

Rear: 175 over 225. Sits about an inch high. Going to try 150/225 then adjust for preload.

- Finished running braided fuel line & evap hose.

- Wired the relocated evap leak detection pump.

- Installed Durango M/C with new hardlines to front/rear axle.

- Current Selection of coils will need new primary coil selection.

Front: 125 over 200. Sits about 1.5" too low. Going to try 150/200 then adjust for preload.

Rear: 175 over 225. Sits about an inch high. Going to try 150/225 then adjust for preload.

New coil setup is much better. Zero preload on the rear, 1.5" up front and frame sits as 21.5".

- Wired the front and rear lockers. Rear works perfectly, front is having issues. Rear locker sensor works with factory Rubicon PCM.

- I somehow, mistakenly, crossed the ram assist hoses. Luckily, field serviceable fittings and I had another piece of hose.

- Almost all exhaust shops around me are booked until October. Looks like I'll be doing it myself.

Started the Jeep yesterday and drove it out. After nearly two years, it fired right up. No CEL with EVAP relocation so that's a plus! Moved it to the other bay, where my lift is. On the lift, it gives a good perspective of what full droop looks like. Front warrants 1" shorter straps or just do the Blaine method and twist the ones I have on, currently.

- Wired the front and rear lockers. Rear works perfectly, front is having issues. Rear locker sensor works with factory Rubicon PCM.

- I somehow, mistakenly, crossed the ram assist hoses. Luckily, field serviceable fittings and I had another piece of hose.

- Almost all exhaust shops around me are booked until October. Looks like I'll be doing it myself.

Started the Jeep yesterday and drove it out. After nearly two years, it fired right up. No CEL with EVAP relocation so that's a plus! Moved it to the other bay, where my lift is. On the lift, it gives a good perspective of what full droop looks like. Front warrants 1" shorter straps or just do the Blaine method and twist the ones I have on, currently.

Wrapped up the exhaust today. I went with 2.25" stainless and a Flowmaster FX muffler. Sound is quite subtle until you step on it. Wrapped the exhaust as components are get real close to the transfer case. Plus my pie-cuts/stainless welding was not the prettiest. Tightened all jamb nuts, greased joints and took it for a ride. Surprisingly, without an alignment, it drove very well. Road manners were as expected. Felt a slight vibration on decelerating but also noticed I failed to tighten rear driveshaft flange so that's probably the root cause. Articulated both sides to check for final clearances. Current spring rates are 150/200 & 150/225 front/rear, respectively. Front has 1.5" of preload and rear has 0". Pictured is about the point where driver-rear will start to come off the ground. At this point, rear passenger and front driver are not fully compressed, or on bumpstops. Secondary coils are now picking up the weight of the corners and not allowing for additional travel.

Debating on trying 175/175 for the front & 175/200 for the rear. They're within a lb or two of the combined stack rate but I fear the stiffer primary coil would yield a more harsh ride. Thoughts?

Debating on trying 175/175 for the front & 175/200 for the rear. They're within a lb or two of the combined stack rate but I fear the stiffer primary coil would yield a more harsh ride. Thoughts?

While waiting for an alignment (scheduled 9/14), I took care of a few odds & ends.

1. Found out I cross-wired the front locker & sensor. Fixed the wiring and now both axle lockers & sensors function properly.

2. Made new front lower fender liners.

3. Applied eastwood internal frame coating.

1. Found out I cross-wired the front locker & sensor. Fixed the wiring and now both axle lockers & sensors function properly.

2. Made new front lower fender liners.

3. Applied eastwood internal frame coating.

While waiting for an alignment (scheduled 9/14), I took care of a few odds & ends.

1. Found out I cross-wired the front locker & sensor. Fixed the wiring and now both axle lockers & sensors function properly.

2. Made new front lower fender liners.

3. Applied eastwood internal frame coating.

View attachment 456307

IT's looking good & I'd imagine it's got to feel GREAT to be driving it.

IT's looking good & I'd imagine it's got to feel GREAT to be driving it.

Thanks. It does feel great driving it and I hope it performs well on the trail. Although, with the time, money and effort spent, the first scratch will hurt.

Well, gremlins are starting to surface. Always typical with a new build. The Jeep went to an offroad shop specializing in 4-wheel alignment. Ocean State Offroad did a great job dialing it in. It's been driving fine for the 30 minutes since completed and test drive was fine. However, just prior to loading it onto the trailer, steering input would not turn passenger! Disconnected the cylinder from the tie-rod and it functioned fine without. Cylinder would not extend, only retract.

I got it onto the trailer and removed the cylinder from the axle when I returned home. I could not turn the rod end by hand. Assuming the shaft was bent, I attempted to remove the gland nut with a pin wrench. However no lukc, and it took a 36" pipe wrench to remove. Yes, I marred up the collar of the gland nut but I'll file it and keep an eye on it. Like a kid on prom night, the shaft was very difficult to pull out. PSC steering made this delrin spacer to limit the stroke to 6" but it's a very tight tolerance to the ID of the cylinder and I suspect, when fully extended, it blocks one of the ports. Or, Delrin swells in oil & heat? either way, I'll turn it down some but hopefully this is the root cause.

@mrblaine ?

I got it onto the trailer and removed the cylinder from the axle when I returned home. I could not turn the rod end by hand. Assuming the shaft was bent, I attempted to remove the gland nut with a pin wrench. However no lukc, and it took a 36" pipe wrench to remove. Yes, I marred up the collar of the gland nut but I'll file it and keep an eye on it. Like a kid on prom night, the shaft was very difficult to pull out. PSC steering made this delrin spacer to limit the stroke to 6" but it's a very tight tolerance to the ID of the cylinder and I suspect, when fully extended, it blocks one of the ports. Or, Delrin swells in oil & heat? either way, I'll turn it down some but hopefully this is the root cause.

@mrblaine ?

Well, gremlins are starting to surface. Always typical with a new build. The Jeep went to an offroad shop specializing in 4-wheel alignment. Ocean State Offroad did a great job dialing it in. It's been driving fine for the 30 minutes since completed and test drive was fine. However, just prior to loading it onto the trailer, steering input would not turn passenger! Disconnected the cylinder from the tie-rod and it functioned fine without. Cylinder would not extend, only retract.

I got it onto the trailer and removed the cylinder from the axle when I returned home. I could not turn the rod end by hand. Assuming the shaft was bent, I attempted to remove the gland nut with a pin wrench. However no lukc, and it took a 36" pipe wrench to remove. Yes, I marred up the collar of the gland nut but I'll file it and keep an eye on it. Like a kid on prom night, the shaft was very difficult to pull out. PSC steering made this delrin spacer to limit the stroke to 6" but it's a very tight tolerance to the ID of the cylinder and I suspect, when fully extended, it blocks one of the ports. Or, Delrin swells in oil & heat? either way, I'll turn it down some but hopefully this is the root cause.

@mrblaine ?

View attachment 457943

Not sure why you are limiting a cylinder to 6" of stroke when they make 6" stroke cylinders but yes, I'd get some room in there for fluid to move around the spacer. If you are careful, you can generally pop the piston and rod out with some air pressure but it can get away from you so if it doesn't move right away, stop or something bad is about to happen.

You could also drill some holes in the spacer.

UKTJ

TJ Addict

...In terms of a forward stretch, I netted 2.5"...

Coming back to an old post I know, but I have been rereading your thread and I found this interesting. I've read a lot elsewhere about how problematic gaining anything at the front is, without moving the steering box, but unless I missed it you did not relocate the steering box. Is that right?

Assuming it is, this seems similar to the result on another JK axle swap that was on YouTube a couple of years back. I appreciate there was a lot of work with the track bar, etc., but changing to the JK axle would mean they needed to be addressed anyway.

Steering box is in the factory location. I'm follwing a build on the FB page "Jeeps with JK/JL axles" and there's someone who claims he got 4" of forward stretch. I can't see how the hell he did (unless he exaggerates).

Steering box is in the factory location. I'm follwing a build on the FB page "Jeeps with JK/JL axles" and there's someone who claims he got 4" of forward stretch. I can't see how the hell he did (unless he exaggerates).

Lots of ways to do it, they will compromise a lot of things in return but it isn't that hard. The main problem is how close you can move the trackbar to the draglink. If you run a short pitman, you can move the trackbar forward and get it out of the way of the axle moving up. Or, don't let the axle move up as high.

The short pitman is going to suck getting the knuckles lock to lock but you can move the axle forward from stock 4".

However, I'm going to go with most of his stretch being the truth. Unless he moved the stock coil spring buckets, a side shot would show what's going on.

Looks like a shorter pitman arm and the track bar is lower than the drag link, in parallel.Lots of ways to do it, they will compromise a lot of things in return but it isn't that hard. The main problem is how close you can move the trackbar to the draglink. If you run a short pitman, you can move the trackbar forward and get it out of the way of the axle moving up. Or, don't let the axle move up as high.

The short pitman is going to suck getting the knuckles lock to lock but you can move the axle forward from stock 4".

However, I'm going to go with most of his stretch being the truth. Unless he moved the stock coil spring buckets, a side shot would show what's going on.

Looks like a shorter pitman arm and the track bar is lower than the drag link, in parallel.

View attachment 458245

That really doesn't get you 4" up front. I'd like to see the wheels straight ahead and full stuff.

Following gear break-in procedure, I put 50 miles on the Jeep yesterday. Took it to a small venue/car show to support PTSD with veterans. Jeep drove very well. So far (knock on wood), no issues with the PSC ram. There's decent low end torque for 37's and 5.13's but 45mph+ and hills, it slows down rather quickly. I have something on an engine stand for that... Anyways, for the 1.5 hrs. I was at the 5 hr. car show, it won best in show..LOL